Method for connecting dry-type high-voltage bushing capacitor core and flange

A capacitor core and high-voltage bushing technology, which is applied in the electrical field, can solve problems such as long-term vibration loosening, stress concentration of clamping structures, etc., and achieve the effects of improving strength, meeting production requirements, and improving connection strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

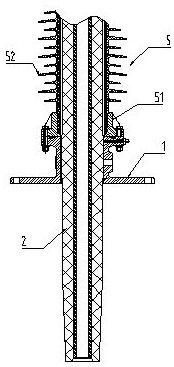

[0032] Embodiment 1: as Figure 1-2 Shown: This embodiment is a method for connecting the dry-type high-voltage bushing capacitor core and the flange, including the following steps:

[0033] Step 1: First car out the connecting thread on the inner wall of flange 1;

[0034] Step 2: Carry out the connecting thread on the outer wall of the dry capacitor core 2;

[0035] Step 3: Put O-ring seal 3 and buffer pad 4 in the sealing groove of flange 1;

[0036] Step 4: apply epoxy glue on the connecting thread of the dry capacitor core 2;

[0037] Step 5: Tighten the dry capacitor core 2 on the flange 1 through the tooling;

[0038] Step 6: Set the insulating sleeve 5 on the upper end of the dry capacitor core 2 and connect it to the flange 1 with bolts.

[0039] The insulating sleeve 5 in step six includes a ceramic sleeve 51 and connecting flanges 52 arranged at both ends of the ceramic sleeve.

[0040] The ceramic sleeve 51 is cast after mixing cement binder and retarder.

[...

Embodiment 2

[0051] Embodiment 2: as Figure 1-2 As shown, this embodiment is a method for connecting the dry-type high-voltage bushing capacitor core and the flange, including the following steps:

[0052] Step 1: First car out the connecting thread on the inner wall of flange 1;

[0053] Step 2: Carry out the connecting thread on the outer wall of the dry capacitor core 2;

[0054] Step 3: Put O-ring seal 3 and buffer pad 4 in the sealing groove of flange 1;

[0055] Step 4: apply epoxy glue on the connecting thread of the dry capacitor core 2;

[0056] Step 5: Tighten the dry capacitor core 2 on the flange 1 through the tooling;

[0057] Step 6: Set the insulating sleeve 5 on the upper end of the dry capacitor core 2 and connect it to the flange 1 with bolts.

[0058] The insulating sleeve 5 in step six includes a ceramic sleeve 51 and connecting flanges 52 arranged at both ends of the ceramic sleeve.

[0059] The ceramic sleeve 51 is cast after mixing cement binder and retarder. ...

Embodiment 3

[0070] Embodiment 3: as Figure 1-2 As shown, this embodiment is a method for connecting the dry-type high-voltage bushing capacitor core and the flange, including the following steps:

[0071] Step 1: First car out the connecting thread on the inner wall of flange 1;

[0072] Step 2: Carry out the connecting thread on the outer wall of the dry capacitor core 2;

[0073] Step 3: Put O-ring seal 3 and buffer pad 4 in the sealing groove of flange 1;

[0074] Step 4: apply epoxy glue on the connecting thread of the dry capacitor core 2;

[0075] Step 5: Tighten the dry capacitor core 2 on the flange 1 through the tooling;

[0076] Step 6: Set the insulating sleeve 5 on the upper end of the dry capacitor core 2 and connect it to the flange 1 with bolts.

[0077] The insulating sleeve 5 in step six includes a ceramic sleeve 51 and connecting flanges 52 arranged at both ends of the ceramic sleeve.

[0078] The ceramic sleeve 51 is cast after mixing cement binder and retarder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com