Display device, preparation method thereof and drying device

A display device and drying device technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems that uneven ink film formation affects the display work of display devices, and achieves improved display work and consistent orientation The effect of improving the consistency of drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

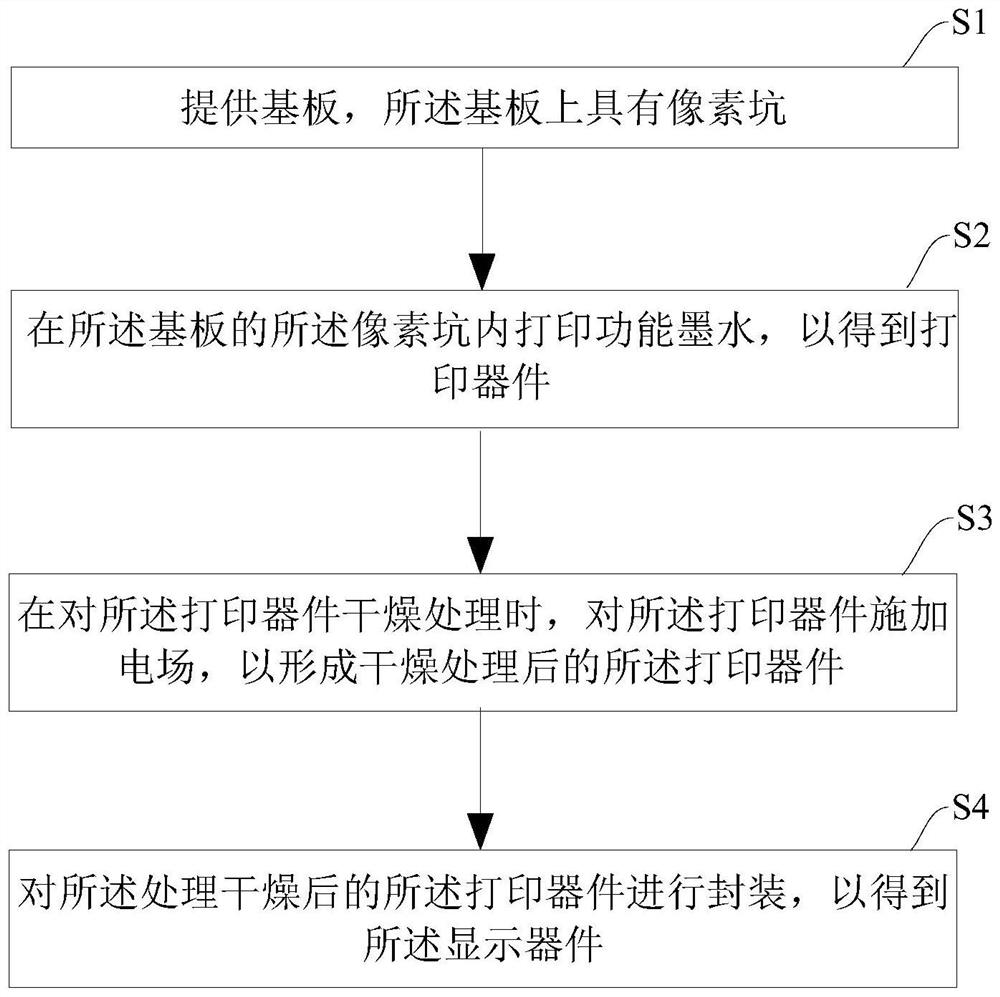

[0063] see figure 1 , figure 1 A flow chart showing a method for manufacturing a display device provided by an embodiment of the present invention includes the following steps:

[0064] S1. Provide a substrate with a pixel cavity on the substrate;

[0065] Wherein, the provided substrate has been subjected to ITO patterning treatment, and the substrate has a pixel cavity for placing ink, and the pixel cavity is defined by the pixel bank on the substrate.

[0066] S2, placing ink in the pixel cavity of the substrate to obtain the printed device 1;

[0067] In this step, the inkjet printing technology is used to place ink in the above-mentioned pixel cavity, that is, a liquid film is printed on the substrate, and the ink forms an ink layer on the pixel cavity of the substrate to obtain the printed device 1, and the printed device 1 is composed of the substrate formed by forming an ink layer on top. Wherein, the ink is an organic ink, which includes a solvent and solute molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com