Vertical basket-free continuous sterilization system

A vertical, sterilizing pot technology, which is applied in toilet sanitary equipment, water supply equipment, heating, etc., can solve the problems of time-consuming and laborious, uneven heating of products, poor continuity, etc., achieve high efficiency, facilitate continuous sterilization, and save up and down effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

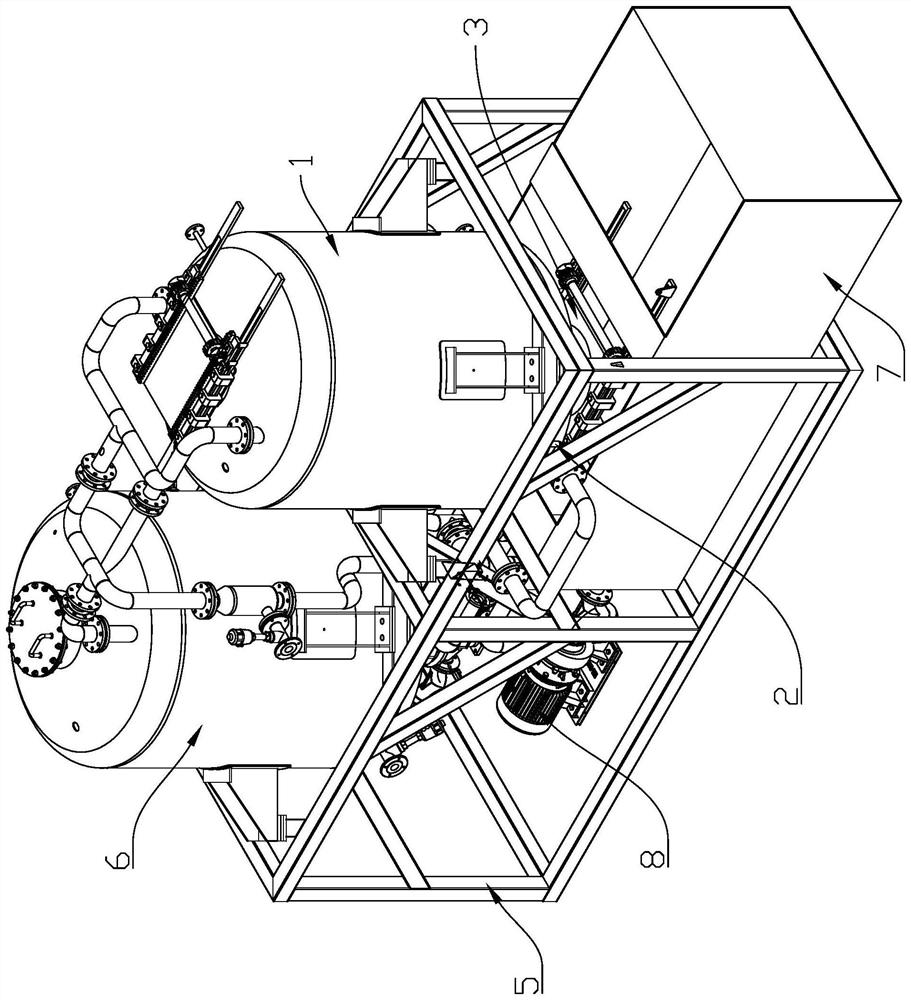

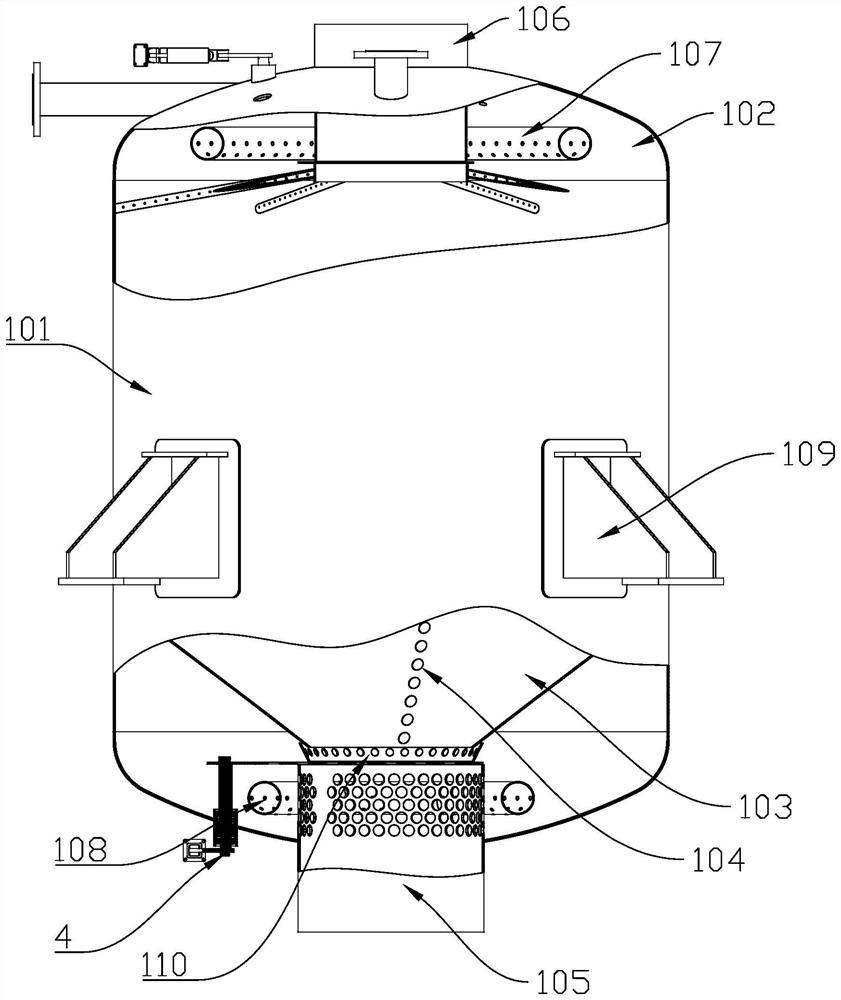

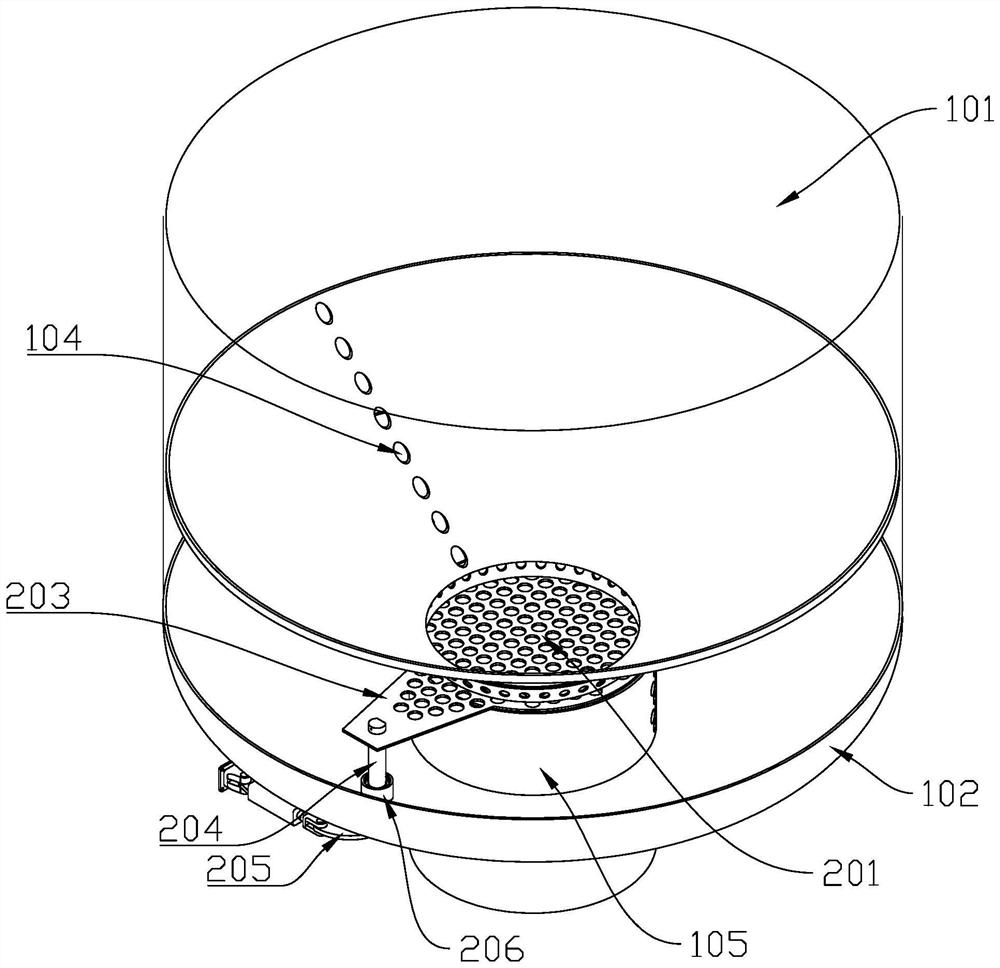

[0030] Such as Figure 1-6 As shown, a vertical basketless continuous sterilization system includes a vertical pot device 1, a pneumatic capping stopper device 2, and an up and down translation door device 3, and the pneumatic capping stopper device 2 is located in the vertical pot device 1 At the inner bottom, the upper and lower translation door devices 3 are respectively arranged at the top feeding port or the bottom feeding port of the vertical pot device 1, and the vertical pot device 1 is fixed on one side of the sterilizing pot frame body 5 for sterilization. The other side of the pot support body 5 is provided with a vertical hot water tank 6 communicating with the vertical pot body device 1, and the bottom of the vertical pot body device 1 is provided with a material receiving pool 7 at the bottom of the sterilizing pot support body 5, The receiving pool 7 is provided with a mesh belt conveyor that extends obliquely upward to the outside of the sterilizing pot frame b...

Embodiment 2

[0036] like Figure 1-4 , 7, a vertical basketless continuous sterilization system, including a vertical pot device 1, a pneumatic capping retaining device 2, an upper and lower revolving door device 4, and the pneumatic capping retaining device 2 is located in the vertical pot body The bottom of the device 1, the upper and lower revolving door devices 4 are respectively arranged at the top feeding port or the bottom feeding port of the vertical pot device 1, and the vertical pot device 1 is fixed on one side of the sterilizing pot frame body 5 , the other side of the sterilizing pot frame body 5 is provided with a vertical hot water tank 6 communicating with the vertical pot body device 1, and the bottom of the vertical pot body device 1 is provided with a receiving pool at the bottom of the sterilizing pot frame body 5 7. A mesh belt conveyor is installed in the material receiving pool 7 and extends obliquely upward to the outside of the sterilizing pot frame body 5;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com