Aluminum profile production equipment and process

A technology of production equipment and production process, applied in the field of aluminum profile production equipment and its production process, can solve the problems affecting the use of aluminum profiles, uneven painting, unstable cutting and fixing of aluminum profiles, etc., to achieve stability and uniform brushing. effect of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

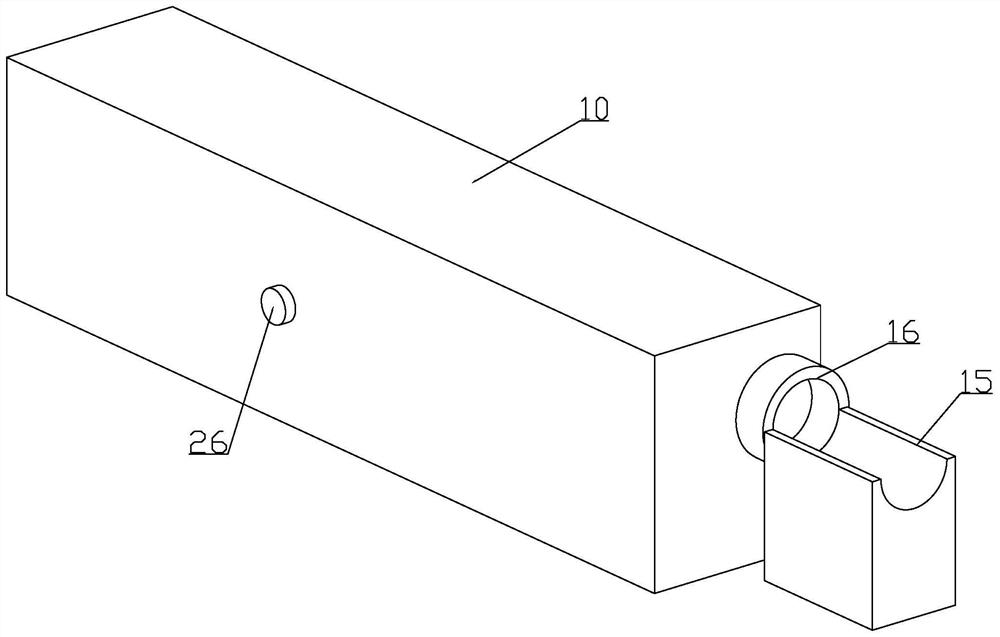

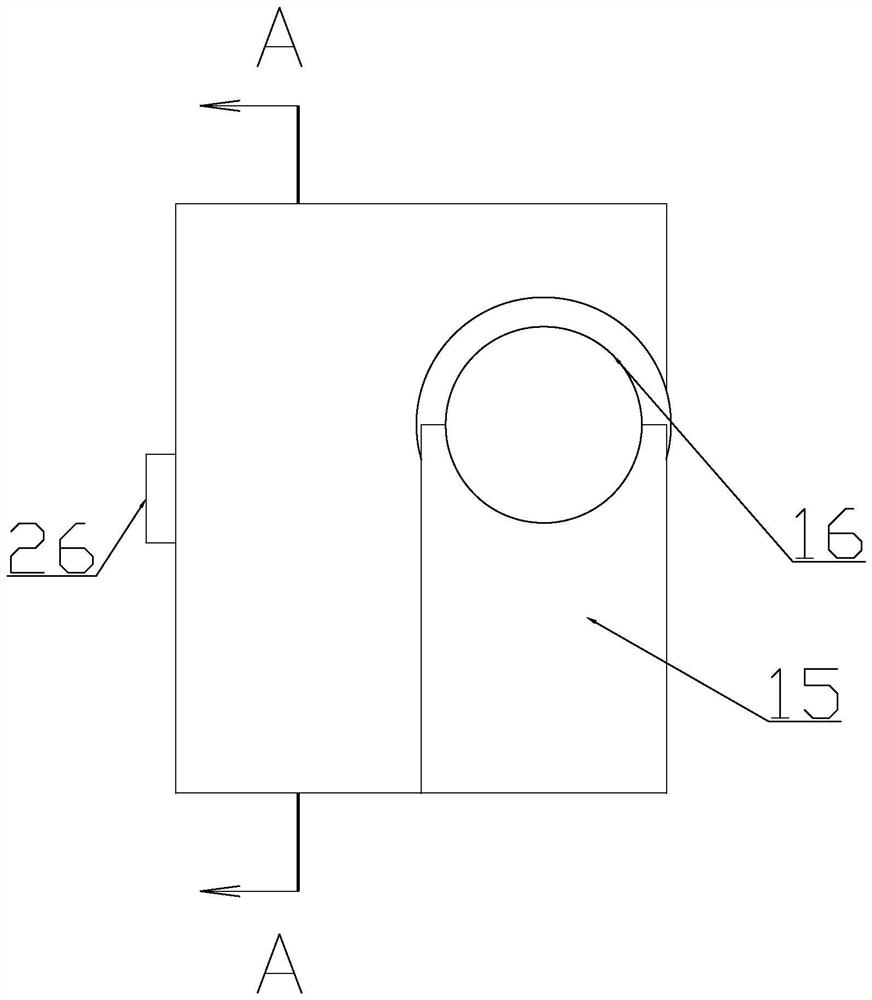

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

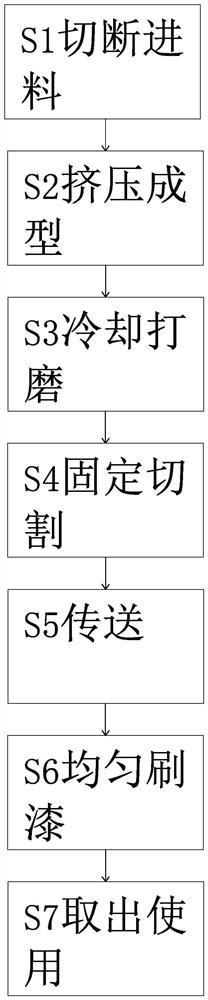

[0040] combine Figure 1-10 , a kind of aluminum profile production equipment and production technology thereof, comprises the following steps:

[0041] S1: Cut off the feed material, cut the heated and softened cast aluminum rod into the required length, and put it into the processing box;

[0042] S2: Extrusion molding, using an extruder to extrude the cut aluminum section into a profile, and extruding and removing the middle of the profile;

[0043] S3: Cooling and grinding, conveying and cooling the aluminum profiles and moving and grinding the aluminum profiles;

[0044] S4: Fixed cutting, stably fix the aluminum profile, and then perform circular cutting;

[0045] S5: Transfer, drop and transfer the cut aluminum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com