Automatic sorting device for appearance inspection of PCB bars

An automatic sorting and appearance inspection technology, which is applied in vibrating conveyors, transportation and packaging, conveyors, etc., can solve the problems of semi-automatic inspection of appearance, inconvenient inspection switching of different products, and inadaptable products, etc., so as to achieve convenient appearance Inspect, improve the efficiency of appearance inspection, and realize the effect of sorting and collecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be further specifically described through the following examples. An automatic sorting device for PCB bar visual inspection is limited.

[0030] In addition, in the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a comprehensive understanding of the embodiments of the present disclosure. It may be evident, however, that one or more embodiments may be practiced without these specific details.

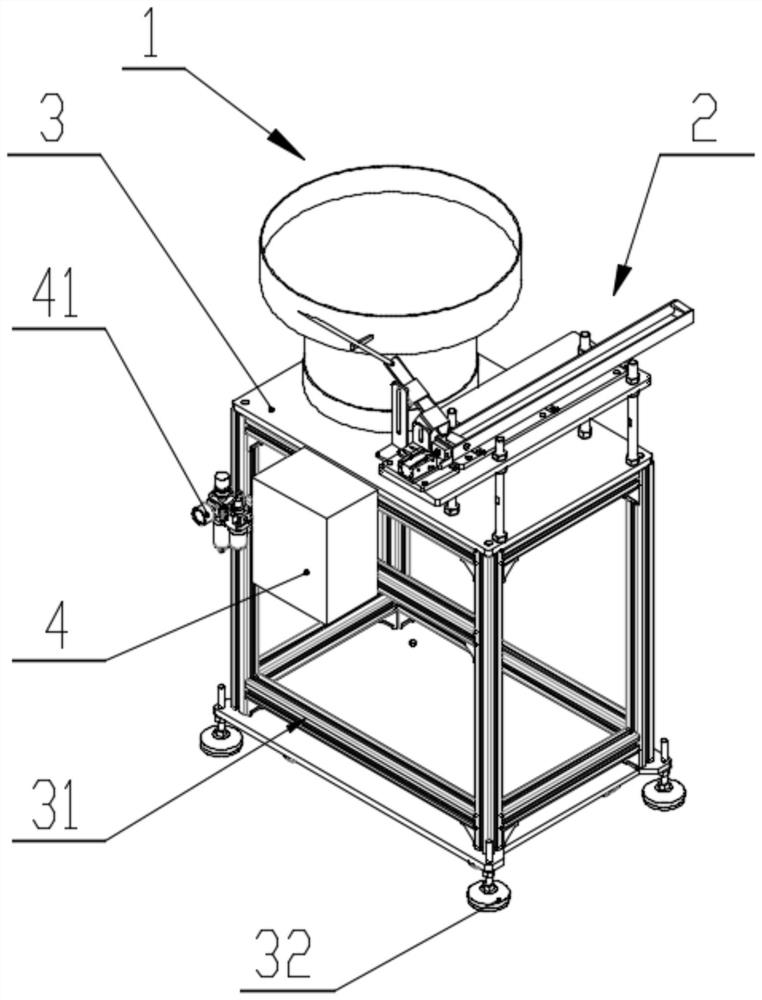

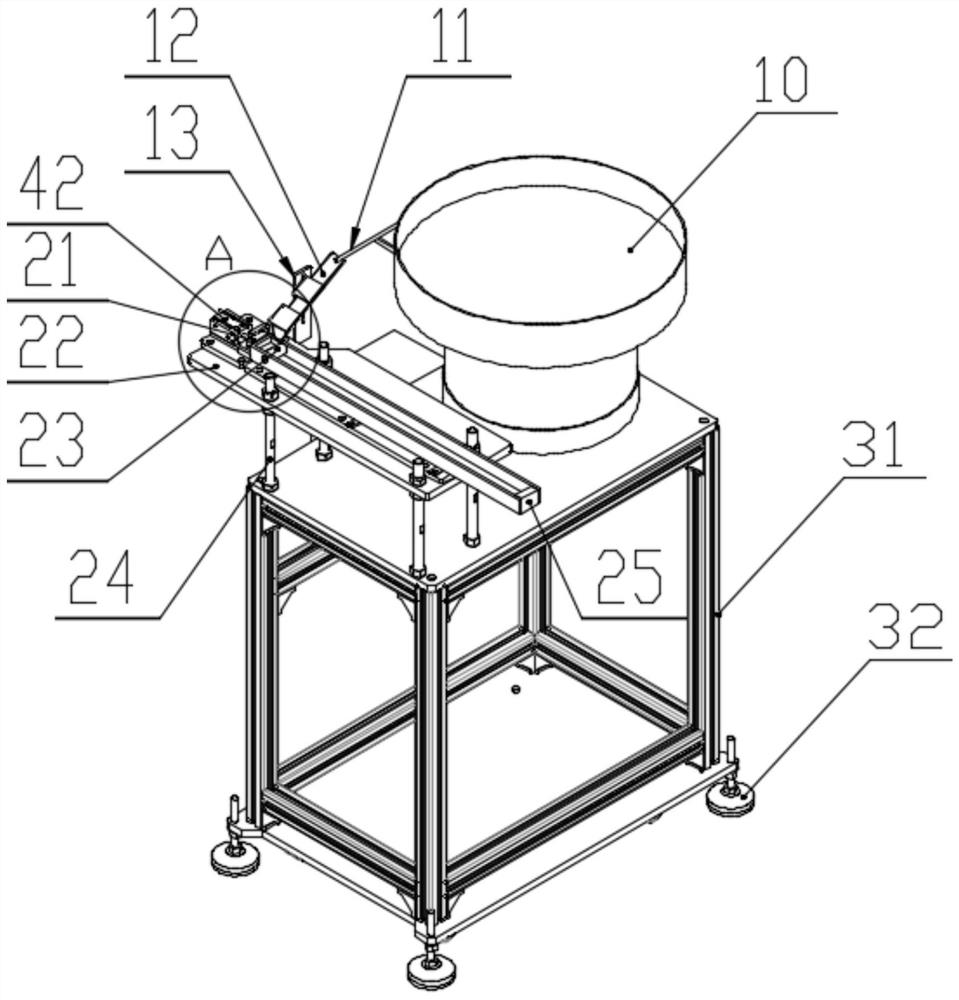

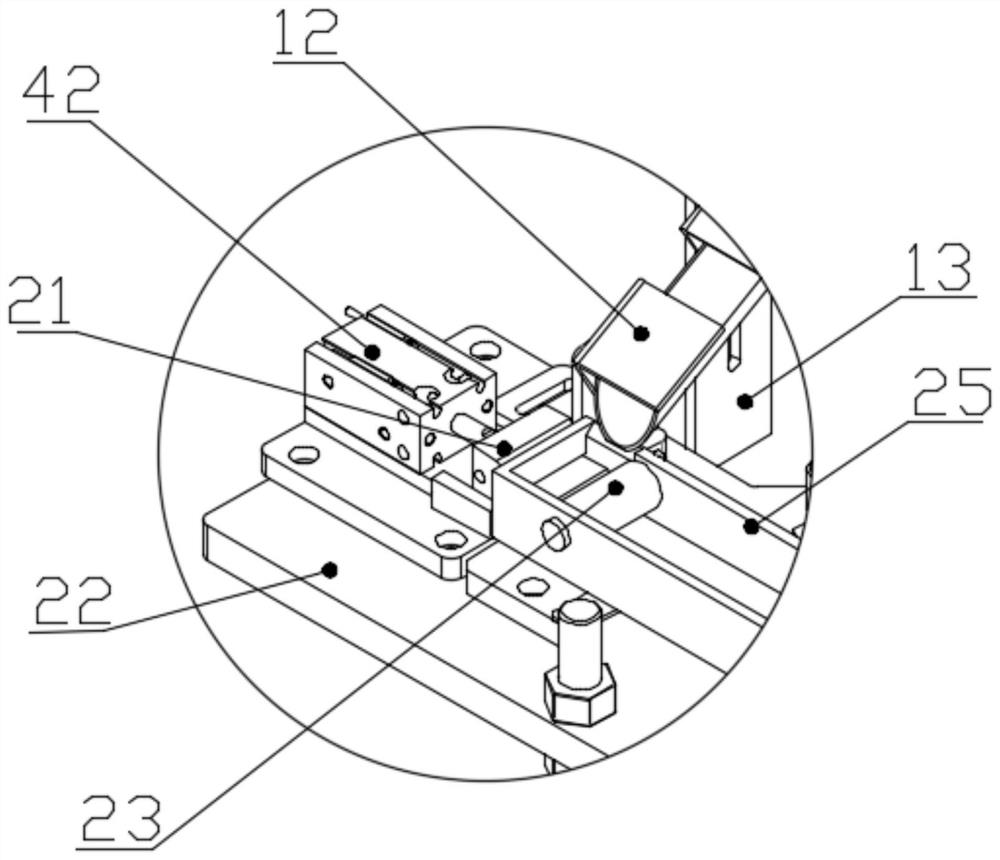

[0031] According to a general technical idea of the present invention, such as Figure 1-3 As shown, an automatic sorting device for PCB bar appearance inspection is provided, including:

[0032] The device main body mechanism 3, the device main body mechanism 3 includes a device frame 31 which plays a supporting role and a device foot 32 arranged at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com