Precise lifting appliance positioning system and method based on machine vision

A precise positioning and machine vision technology, which is applied in the field of precise positioning system for spreaders based on machine vision, can solve the problem that the positioning accuracy of engineering crane hoisting points cannot reach the millimeter level, so as to improve safety and reliability, and improve detection accuracy , the effect of increasing redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better understand the above technical solution, the above technical solution will be described in detail below with reference to the drawings and specific embodiments.

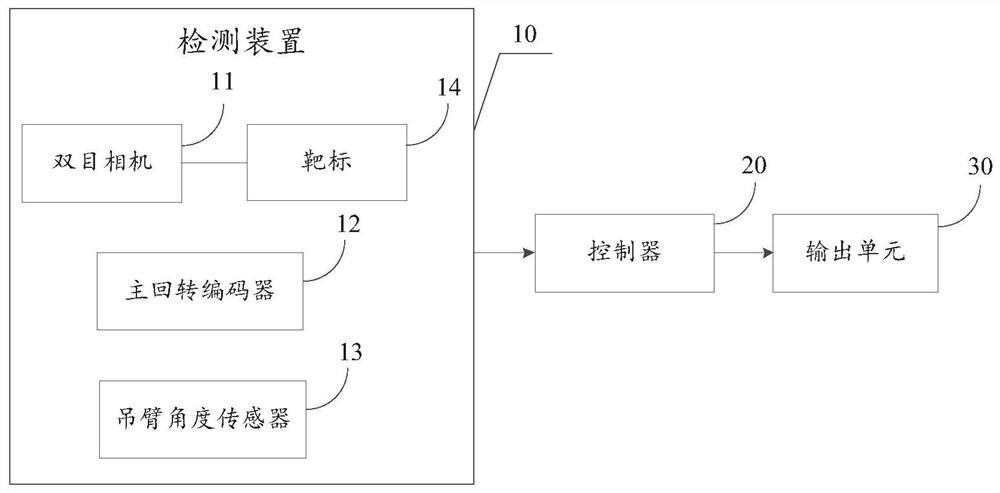

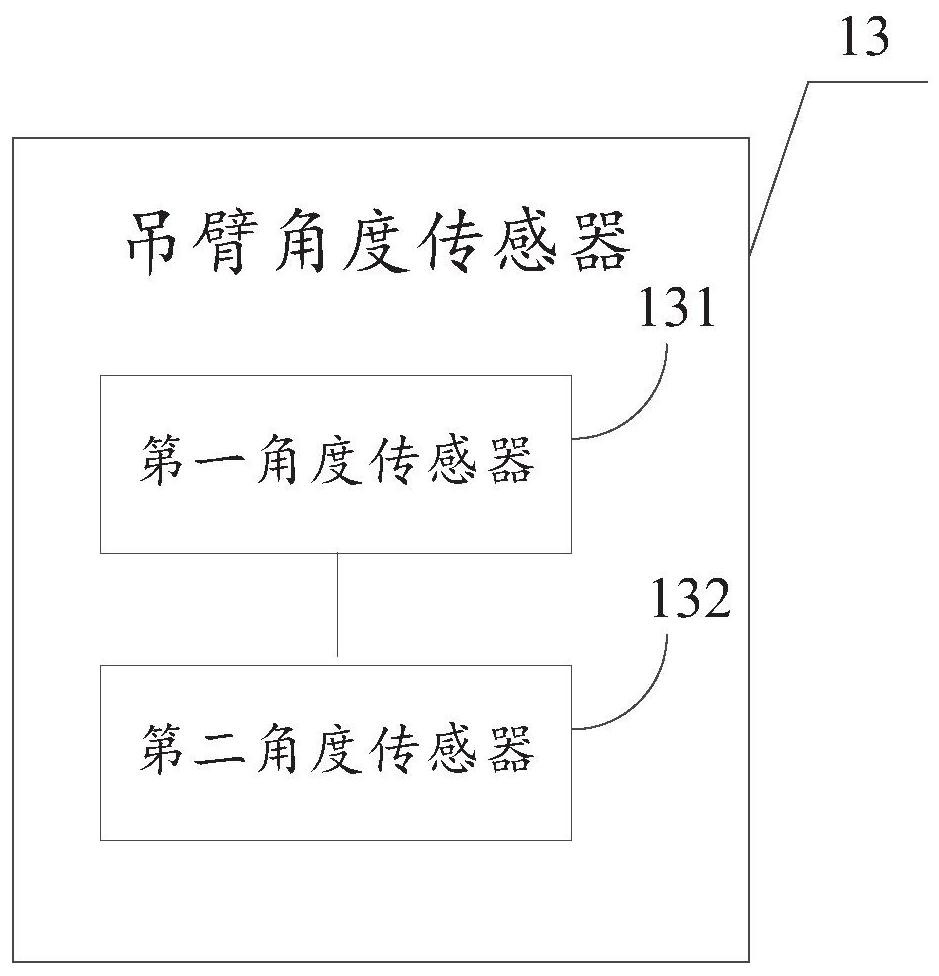

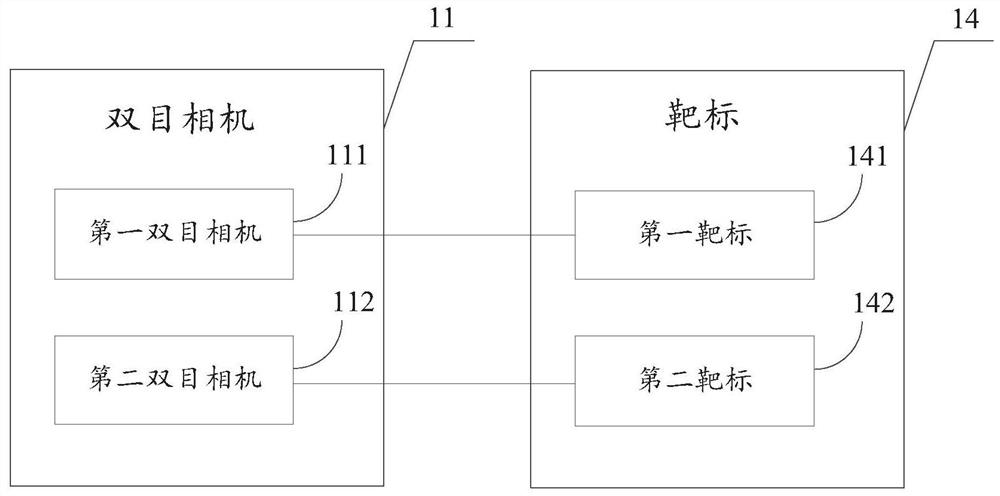

[0054] like figure 1 As shown, the first embodiment of the present invention proposes a machine-based spreader precision positioning system, including the detecting device 10, the controller 20, and the output unit 30, wherein the detecting device 10 is used to obtain a hoisting vehicle spreader 100 and The position information of the load 200, the detecting device 10 includes a binocular camera 11, the main autorector 12, and the boom angle sensor 13 on the spreader, and the budget camera 11 is used to identify the target 14 on the load 200 for identification. The target 14 on the load 200 acquires the position information of the load 200; the main auto-rotation encoder 12 is used to detect the main rotation angle of the lifting vehicle in real time; the boom angle sensor 13 is used to detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com