Connecting structure and method for prefabricated veneer and prefabricated concrete external wall panel

A technology of prefabricated concrete and connecting structures, which is applied in building construction, covering/lining, construction, etc., can solve the problems of environmental pollution at the construction site, low construction efficiency, and many construction procedures, and achieve the reduction of wet work load, safety and The effect of high stability and simple construction of the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

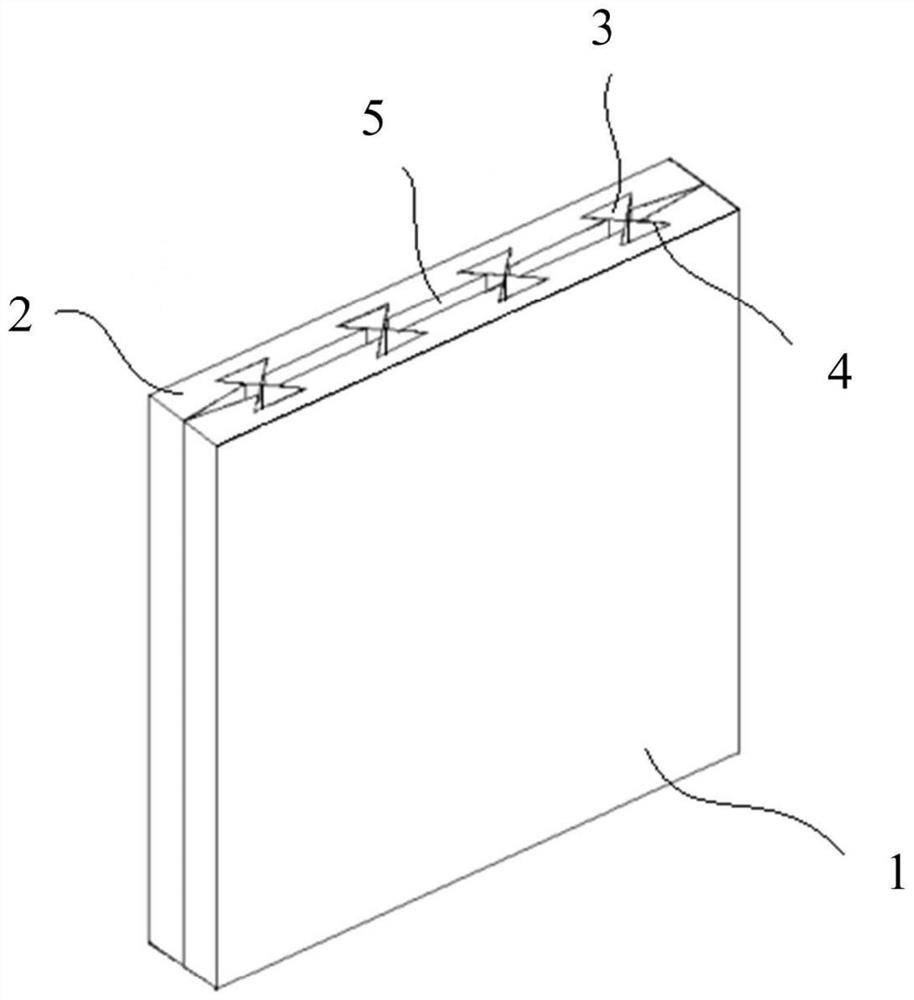

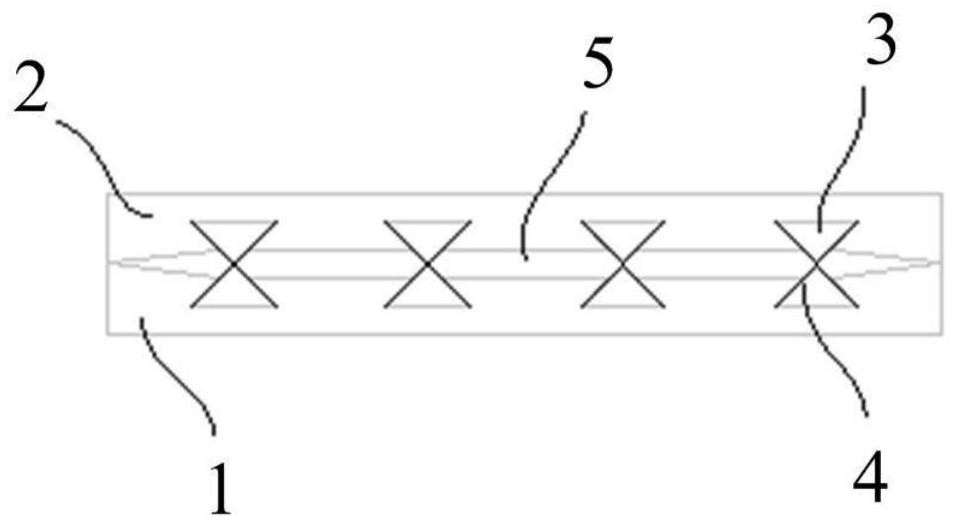

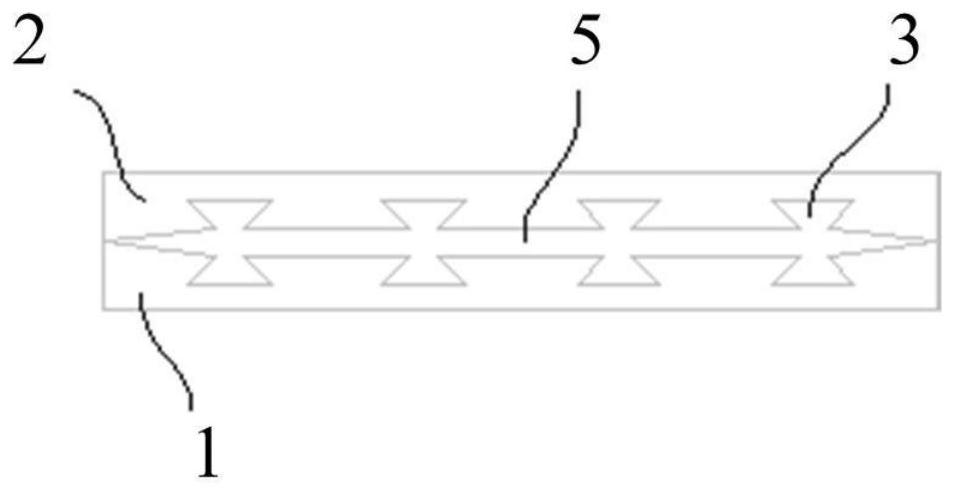

[0032] Combine below Figure 1 to Figure 5 , detailing the structural composition of the connection structure between the prefabricated decorative panel and the prefabricated concrete exterior wall panel of the present invention.

[0033] Please refer to Figure 1 to Figure 5 , a connection structure between a prefabricated decorative panel and a prefabricated concrete exterior wall panel, comprising a prefabricated decorative panel 1, a precast concrete exterior wall panel 2, and a clip 4, two board surfaces where the prefabricated decorative panel 1 and the precast concrete exterior wall panel 2 are butted There are several grooves 3 along the thickness direction, and the grooves 3 are arranged at intervals along the length direction of the board surface; after the prefabricated decorative panel 1 and the prefabricated concrete exterior wall board 2 are docked and clamped, the grooves are arranged one by one along the length direction of the board surface. Correspondingly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com