Steel frame shear wall structure system and implementation method thereof

A shear wall and steel frame technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of cumbersome technological process, inability to synchronously assemble and construct the steel frame, and the connection between the prefabricated shear wall and the steel frame is not reliable and stable enough. , to achieve the effect of good integrity, improved lateral stiffness and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] A method for implementing a steel frame shear wall structure system, comprising the steps of:

[0034] S1. Assemble and install the prefabricated "H"-shaped steel lattice columns and steel beams; the assembly method is welding or high-strength bolt connection;

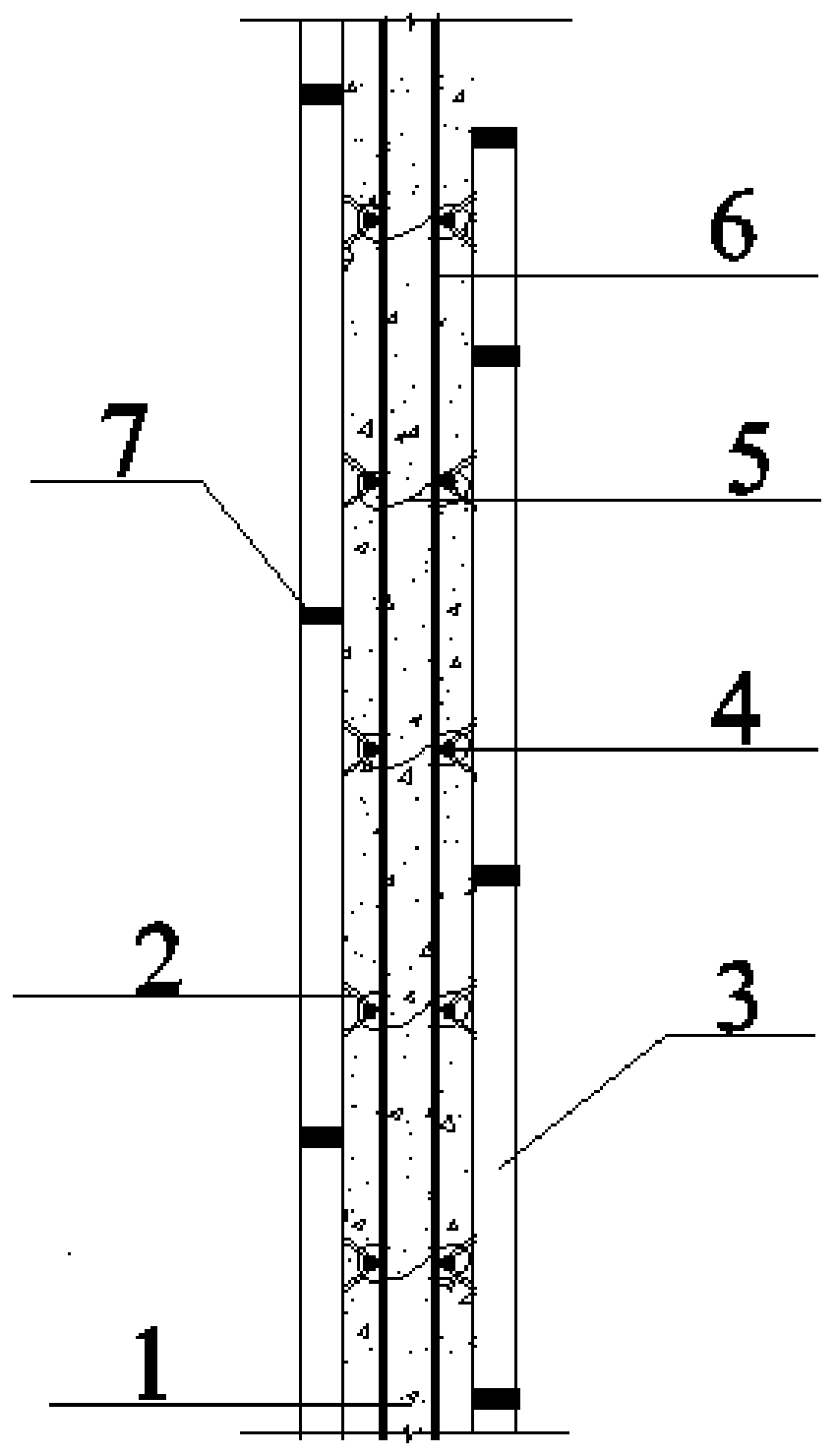

[0035] S2. The precast concrete wall panel 3 has a thickness of 50mm and a height of 600mm. The precast concrete wall panel 3 is placed with grid steel bars 2 during prefabrication, and the grid steel bars 2 are arranged in a vertical linear array along the precast concrete wall panel 3; the grid Steel bar 2 plays the role of bearing the load and fixing the stressed steel bar of the shear wall;

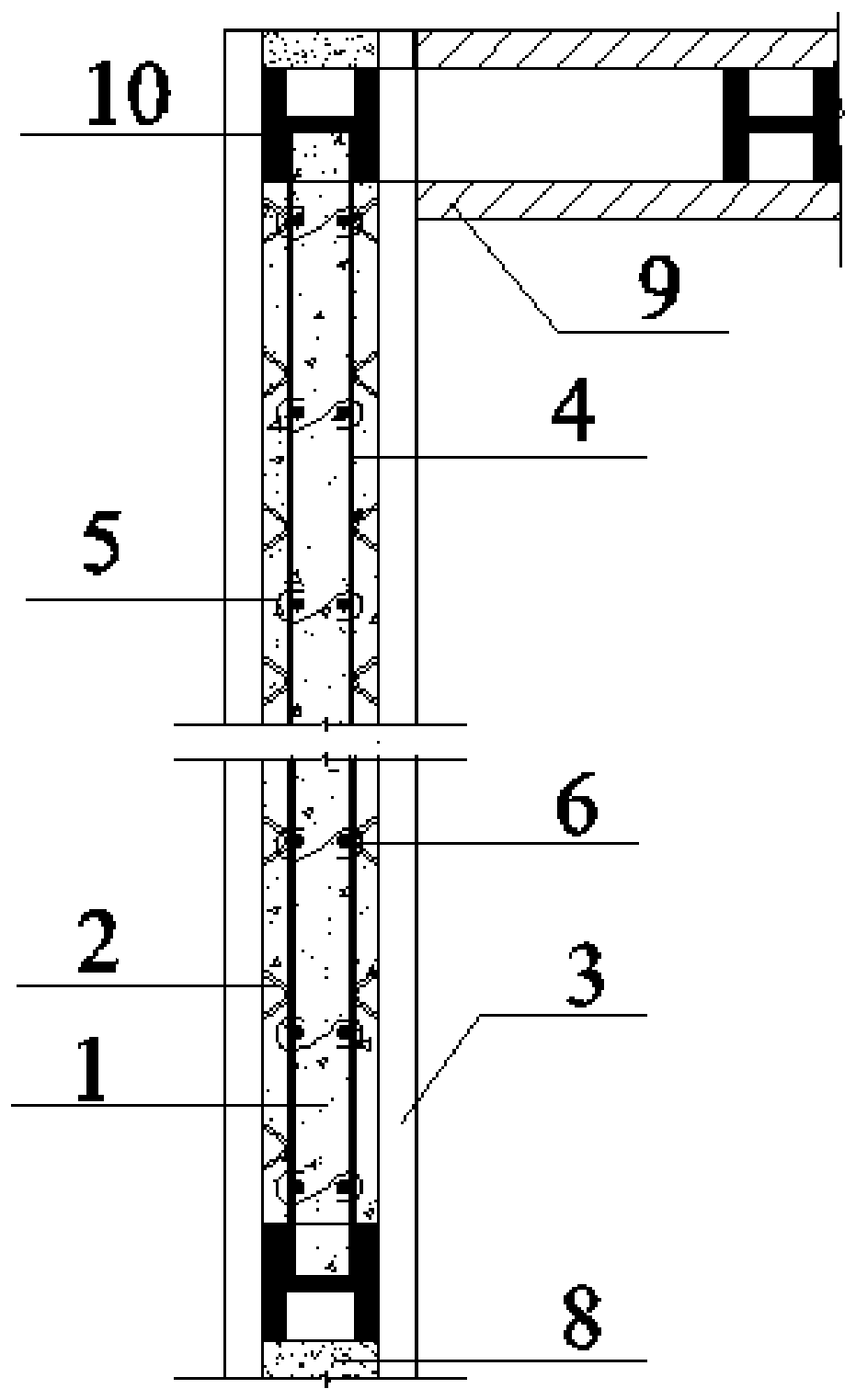

[0036] S3, assemble and install the prefabricated concrete wall panel 3 through the pre-embedded angle steel and steel column 10 on site, and set rubber plugs 8 at both ends of the wall panel to prevent the slurry from running out when pouring concrete;

[0037] S4. The prefabricated concrete wall panels 3 are welded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com