Ventilator non-stop switching system

A ventilator and reverse machine technology, applied in the direction of machine/engine, mechanical equipment, pump control, etc., can solve problems such as safety accidents, expansion, safety hazards, economic losses, etc., to improve work efficiency, increase economic benefits, and achieve remarkable results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

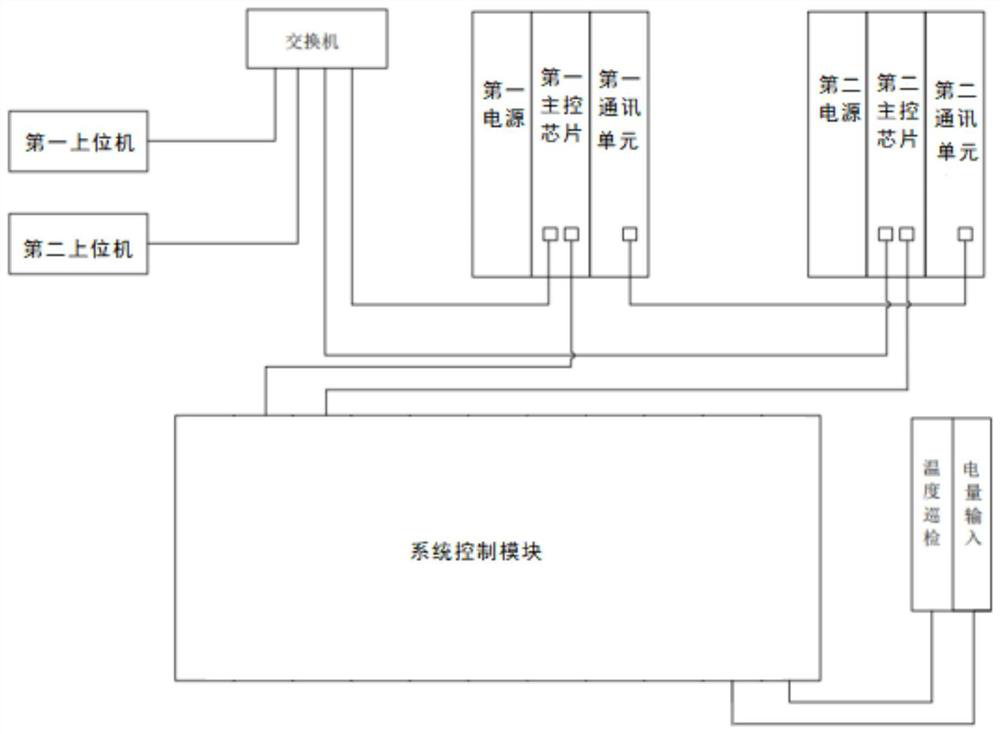

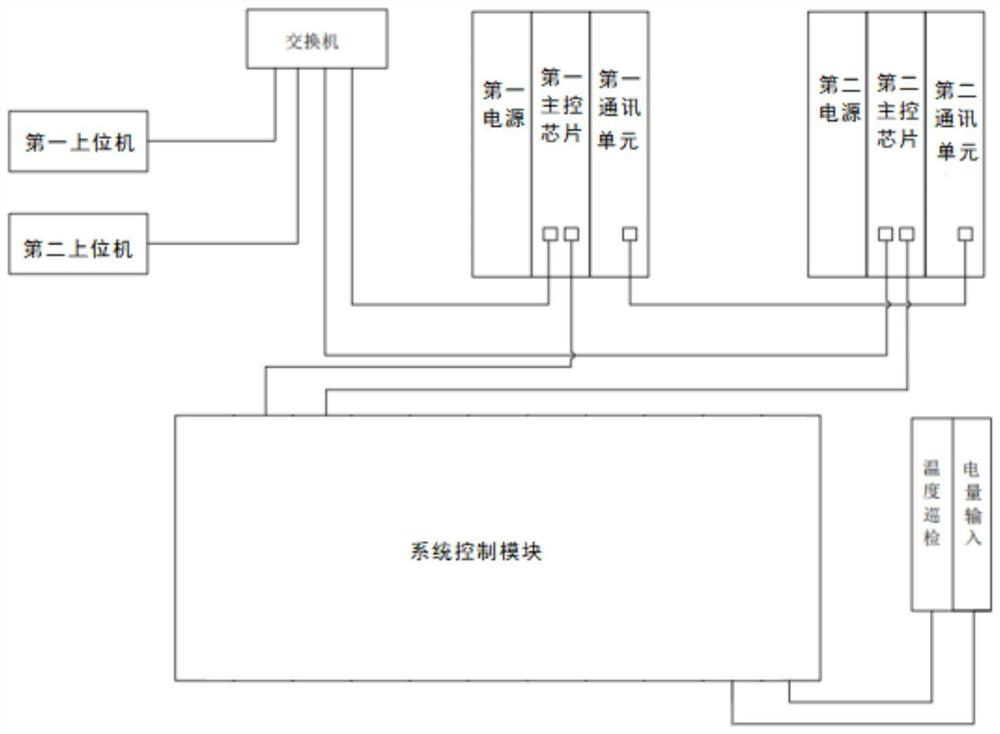

[0021] figure 1 The ventilator non-stop shutdown system shown includes a host computer module, a switch module, a central control processing module, a system control module and a fan module, and the communication serial port of the host computer module passes through the communication serial port of the switch module and the central control processing module Connection, the communication serial port of the central control processing module is connected with the communication serial port of the system control module, the signal output terminal of the system control module is connected with the signal input terminal of the fan module, and the communication serial port of the fan module communicates with the communication serial port of the system control module bidirectionally .

[0022] The upper computer module includes a first upper computer and a second upper computer, and the communication serial ports of the first upper computer and the second upper computer are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com