Pipe hoop-shaped parallel broadband particle damper and design method thereof

A particle shock absorber, parallel technology, applied in the design characteristics of spring/shock absorber, shock absorber, inertia effect shock absorber, etc., can solve maintenance difficulties, high cost of shock absorber, limited use of space, etc. problem, to achieve the effect of flexible application, good vibration reduction effect and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

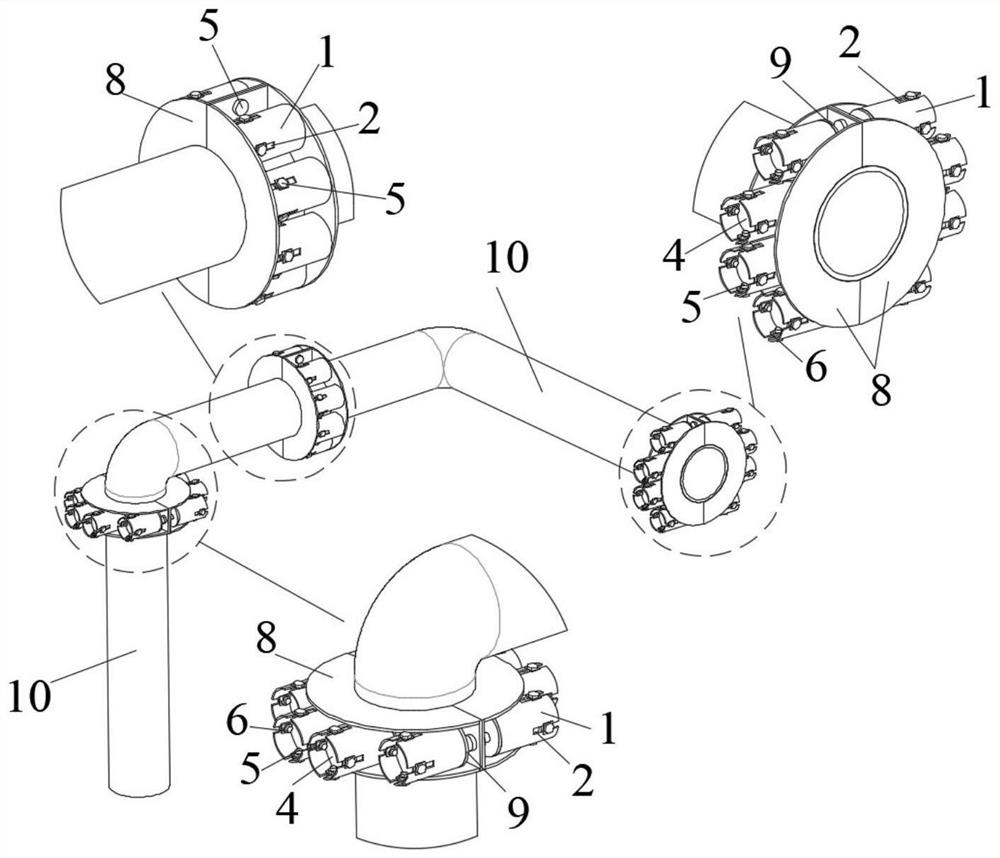

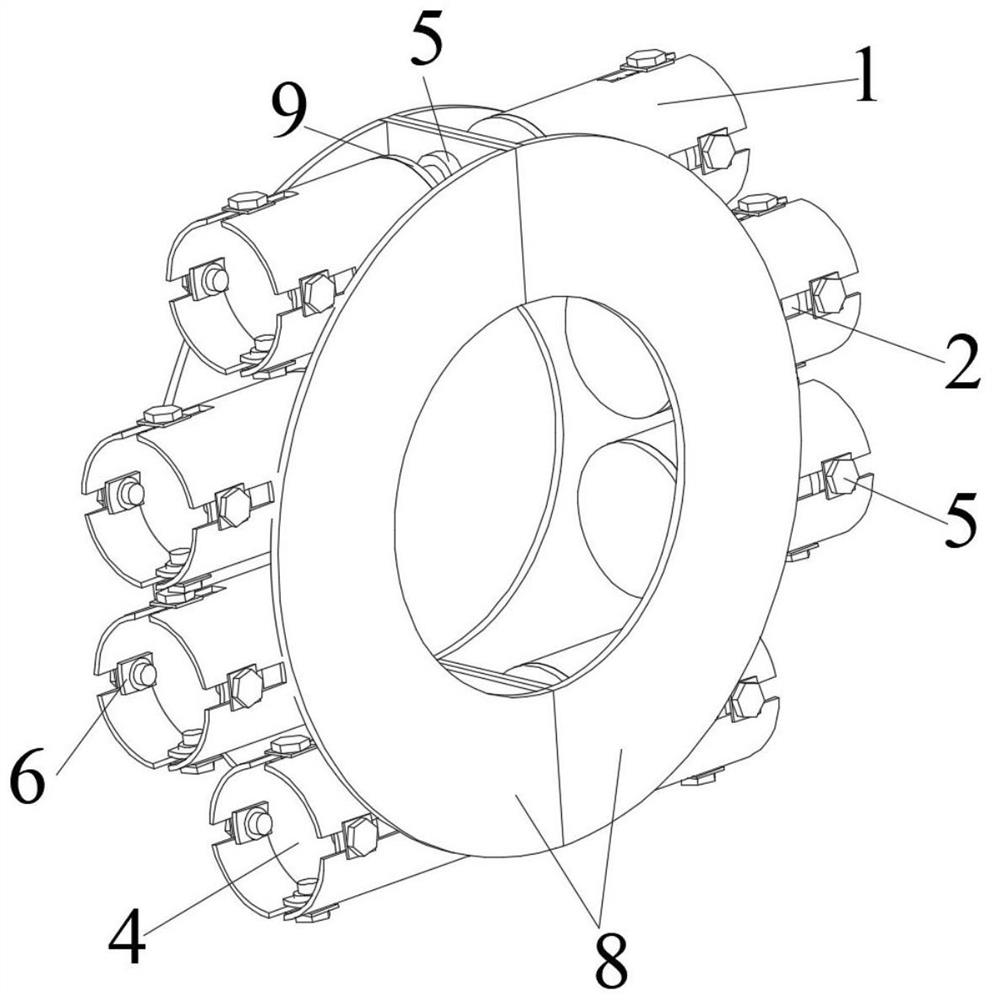

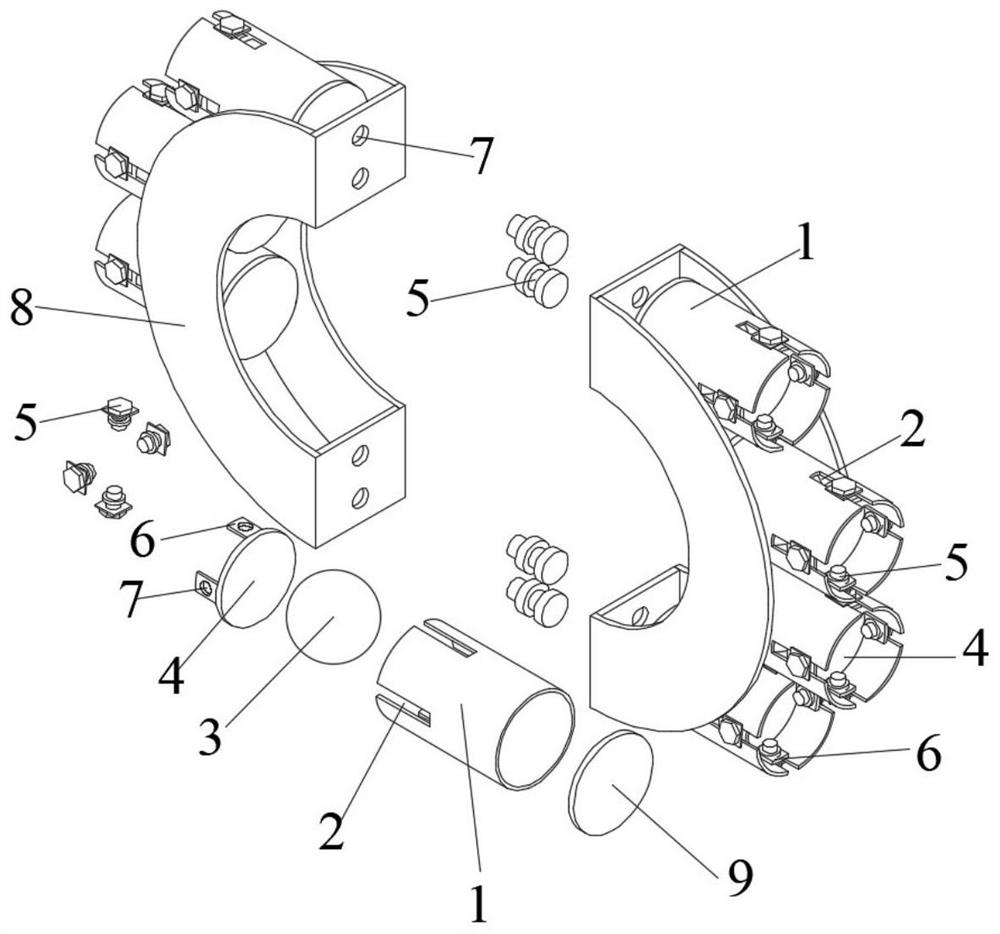

[0057] Please refer to the attached Figure 1-13 , the purpose of this embodiment is to provide a tubular hoop-shaped parallel broadband particle damper, including: a multi-section tubular structure 10, the tubular structure 10 is circular or square, so as to be suitable for various types of cross-sections 10 Vibration reduction of tubular structure. A parallel broadband particle damper is arranged between the multi-section tubular structures 10; the parallel broadband particle damper consists of a tubular hoop-shaped parallel broadband particle damper for axial vibration reduction, and a radial vibration damper for radial vibration reduction. It is composed of a tubular hoop-shaped parallel broadband particle damper.

[0058] Among them, the tubular hoop-shaped parallel broadband particle damper for axial vibration reduction is provided with a cylindrical cavity 1 whose axis is parallel to the axis of the tubular structure 10, and a cylindrical cavity whose axis is parallel ...

Embodiment 2

[0064] The purpose of this embodiment is to provide a design method for a tubular hoop-shaped parallel broadband particle damper, including the following steps: determining the total mass and number of particles 3 in the tubular hoop-shaped parallel broadband particle damper , radius and movement distance; according to the design information of the particle 3, the size of the two cylindrical cavities 1 and the size of the elongated hole 2 are determined.

[0065] Specifically, the vibration characteristics of the tubular structure 10 include mass m, damping coefficient c and stiffness k, and the displacement, velocity and acceleration of the tubular structure 10 are x, and The mass m is the sum of the mass of the tubular structure 10 and other components in the particle damper except the particle 3, and the mass of the particle 3 is m p , the displacement, velocity and acceleration of particle 3 are x p , and d is the movement distance of the particles 3, g is the acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com