Method for estimating productivity of circular weft knitting machine

A circular knitting and weft knitting technology, applied in the field of knitting production, can solve the problems of not being universally applicable and having many parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for estimating the production capacity of single-sided plain weave fabrics produced by a circular weft knitting machine according to the present invention.

[0043] Include the following steps:

[0044] Fabrics are produced using circular weft knitting machines at specific machine speeds;

[0045] Measure and record the width and grammage of the fabric;

[0046] Measure and record the longitudinal density of the fabric;

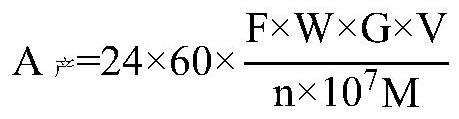

[0047] Calculate and adopt described weft knitting circular machine to estimate the one-day production capacity of described fabric production according to following formula:

[0048]

[0049] in,

[0050] A 产 The estimated production capacity of fabrics produced by the weft knitting circular machine in one day, unit: kg;

[0051] F is the number of knitting systems that participate in weaving when the weft knitting machine produces the fabric;

[0052] W is the width of the fabric, unit: cm;

[0053] G is th...

Embodiment 2

[0061] The difference from Example 1 is that this example provides a method for estimating the production capacity of a weft knitting circular machine for producing double-sided plain weave + mesh fabrics.

[0062] This process is double-sided jacquard mesh fabric, the parameters are: model 20"14G8F, width 137cm, weight 330g / m 2 , the machine speed is 20r / min, the longitudinal density is 13.3 needles / cm, and the cloth surface is 2 lines and 1 line, that is, n=2, so the formula is calculated as follows:

[0063]A=24×60×8×137×330×20 / (2×10 7 ×13.3)=39.16 (kg / day).

[0064] In summary, this type of double-sided jacquard mesh fabric has a theoretical production capacity of 39.16kg / day, while the actual production capacity is 40kg / day, and the error between the calculated theoretical production capacity and the calculated theoretical production capacity data is 2.16%.

Embodiment 3

[0066] Different from Embodiments 1 and 2, this embodiment provides an estimate of the production of weft-knitted ordinary sandwiches by a weft-knitting circular machine.

[0067] This process is Sandwich Minari, the parameters are: model 34"24G72F, width 147.32cm, weight 277g / m 2 , the machine speed is 15r / min, the longitudinal density is 26 needles / cm, and the cloth surface is 3 lines and 1 line, that is, n=3, so it is substituted into the formula:

[0068] A=24×60×72×147.32×277×15 / (3×10 7 ×26)=81.36 (kg / day).

[0069] In summary, this type of double-sided jacquard mesh fabric has a theoretical production capacity of 80kg / day, while the actual production capacity is 81.36kg / day, and the error between the theoretical production capacity and the calculated theoretical production capacity data is 1.67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com