Preparation method and test of wear-resistant concrete

A technology of concrete and cement concrete, which is applied in the field of suggested materials, can solve the problem of high cost of high wear-resistant aggregates, and achieve the effect of improving wear resistance, improving mechanics and wear resistance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention will be described in further detail below.

[0053] A wear-resistant concrete, which is made of the following components in parts by weight: 240-270 parts of ordinary portland cement, 80-90 parts of slag, 618 parts of machine-made sand, 60 parts of 5-10mm gravel, 10-20mm 299 parts of gravel, 839 parts of 16-31.5mm gravel, 106-119 parts of water, and 2.88-4.07 parts of water reducing agent. Ordinary Portland cement 235 parts, slag 85 parts, 27.5mm gravel 839 parts, water 110 parts, water reducing agent 3.5 parts.

[0054] A method for preparing wear-resistant concrete, characterized in that the specific steps are as follows:

[0055] S001: Add 60 parts of 5-10mm crushed stone, 299 parts of 10-20mm crushed stone, 839 parts of 16-31.5mm crushed stone and 618 parts of machine-made sand into the mixer, and stir for 1 minute;

[0056] S002: Add 240 parts of ordinary Portland cement and 80 parts of slag to the mixture in step S001, and stir for 1 minute; then a...

PUM

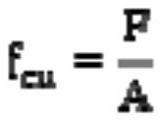

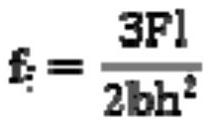

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com