Anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling and its preparation method and application

A technology of hot rolling forming, anti-friction and anti-wear, applied in the field of anti-friction and anti-wear, to achieve the effect of convenient operation, simple process, protection and anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

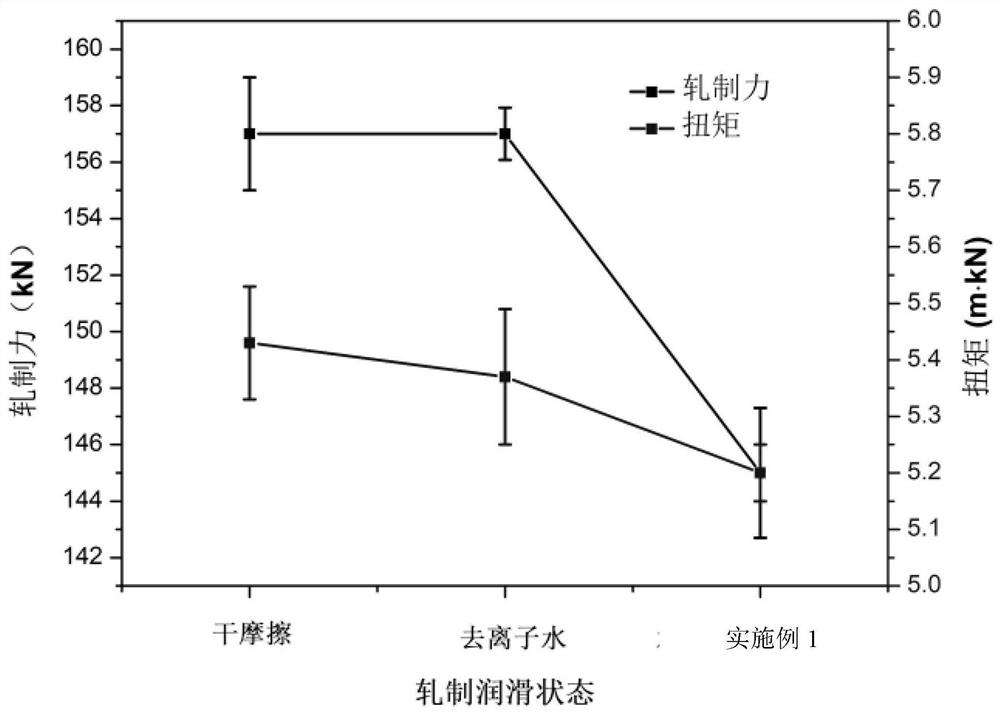

Embodiment 1

[0038] A method for preparing an anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling, comprising the following steps:

[0039] To 20 parts by mass of talc (with a particle size of 10-30 μm) and 5 parts by mass of Na 2 SiO 3 (particle diameter is 10~30 μ m) add in the water of 75 mass parts, obtain the talc water-based suspension; Then add the isobutyl vinyl ether / maleic anhydride copolymer of 1 mass part in the talc water-based suspension, After ultrasonic vibration for 2 hours, the metal hot rolling forming anti-friction, anti-wear and anti-oxidation lubricant is obtained.

[0040] The method for using the anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming includes the following steps:

[0041] Coat the surface of the steel plate (width 65mm×length 203mm×height 20mm) preheated to 150°C with a layer of anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming, so that the anti-friction, anti-wea...

Embodiment 2

[0044] A method for preparing an anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling, comprising the following steps:

[0045] To 5 parts by mass of talc (with a particle size of 10-30 μm) and 5 parts by mass of Na 2 SiO 3 (Particle diameter is 10~30 μm) add 90 mass parts waters, obtain the talc water-based suspension; Then add the isobutyl vinyl ether / maleic anhydride copolymer of 1 mass part in the talc water-based suspension, ultrasonic After vibrating for 2 hours, the anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling is obtained.

[0046] The method for using the anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming includes the following steps:

[0047] Coat the surface of the steel plate (width 65mm×length 203mm×height 20mm) preheated to 150°C with a layer of anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming, so that the anti-friction, anti-wear and anti-oxid...

Embodiment 3

[0050]A method for preparing an anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling, comprising the following steps:

[0051] To 45 parts by mass of talc (with a particle size of 10-30 μm) and 10 parts by mass of Na 2 SiO 3 (Particle diameter is 10~30 μ m) add 45 mass parts in water, obtain the talc water-based suspension; Then add 5 mass parts of isobutyl vinyl ether / maleic anhydride copolymer in the talc water-based suspension, ultrasonic After vibrating for 2 hours, the anti-friction, anti-wear and anti-oxidation lubricant for metal hot rolling is obtained.

[0052] The method for using the anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming includes the following steps:

[0053] Coat the surface of the steel plate (width 65mm×length 203mm×height 20mm) preheated to 150°C with a layer of anti-friction, anti-wear and anti-oxidation lubricant for metal hot-rolled forming, so that the anti-friction, anti-wear and anti-oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com