A sealed laser cleaning device for easily oxidized parts

A laser cleaning, easy-to-oxidize technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of oxidation, not easy to move, large volume and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

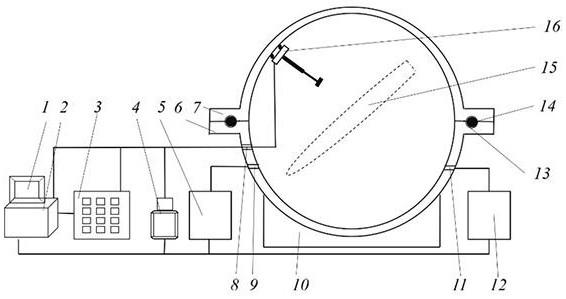

[0016] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings.

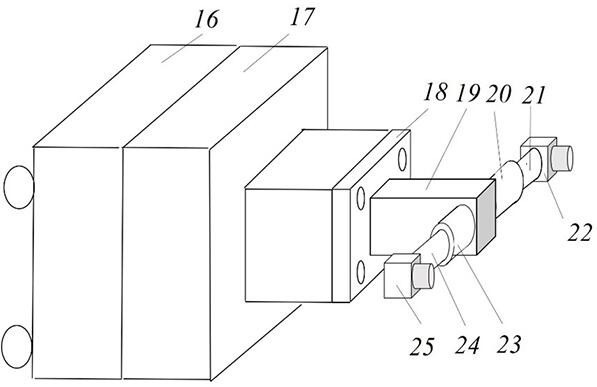

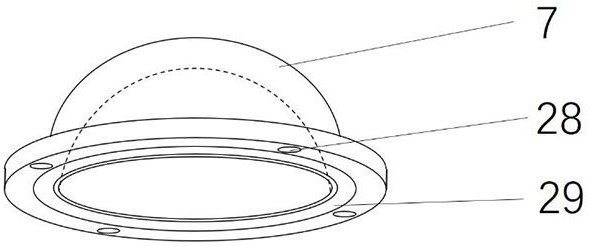

[0017] Such as figure 1 As shown, a sealed laser cleaning device for easily oxidized parts provided in this embodiment includes a computer 1, a controller 2, a laser generator 3, a hydraulic cylinder 4, a ventilation device 5, a lower hemispherical shell 6, and an upper hemispherical shell 7 , transmission hole 8, air inlet hole 9, base 10, air outlet hole 11, gas collecting device 12, second sealing groove 13, sealing strip 14, parts to be washed 15, crawling robot 16, telescopic rod 17, connecting plate 18, connecting Block 19, second motor 20, second motor shaft 21, ranging sensor 22, first motor 23, first motor shaft 24, cleaning equipment 25, fixture 26, second mounting hole 27, first mounting hole 28, the first A sealing groove 29.

[0018] Such as figure 2 As shown, the laser cleaning device 25 is installed on the first rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com