Aluminum-magnesium alloy metal product with high welding property and oxidation resistance

A technology of anti-oxidation performance and metal products, applied in the direction of coating, etc., can solve the problem that the welding performance, metal mechanical properties and anti-oxidation performance cannot reach higher performance, affect the use performance, damage the welding performance and metal machinery of aluminum-magnesium alloys. performance and other issues, to achieve the effect of protecting anti-oxidation performance, improving welding performance, and avoiding oxidation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments of the present invention.

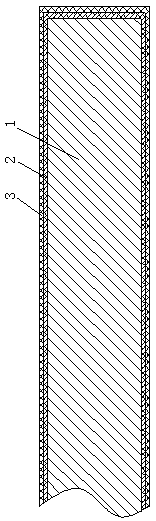

[0035] Such as figure 1 As shown, the aluminum-magnesium alloy metal product with high weldability and oxidation resistance includes: a metal product body 1 that mainly meets the use requirements and ensures the strength of the metal product, and a welding layer that improves the welding performance between the metal product bodies 1 2, and an anti-oxidation layer 3 that isolates the external environment and prevents the metal product body 1 and the welding layer 2 from being oxidized.

[0036] In order to achieve the required technical effect of each layer, according to the weight ratio, the chemical composition content of each layer is respectively:

[0037] The metal product body 1 includes 0.0773%~0.0986% scandium; by adding a trace amount of scandium element composition, the fusion with the welding layer 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com