Multi-element alloy probe for semiconductor testing and manufacturing method of multi-element alloy probe

A multi-component alloy and manufacturing method technology, applied in the field of probe card testing, can solve problems such as complex processes, and achieve the effects of wide adaptability, low production cost, and short probe cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

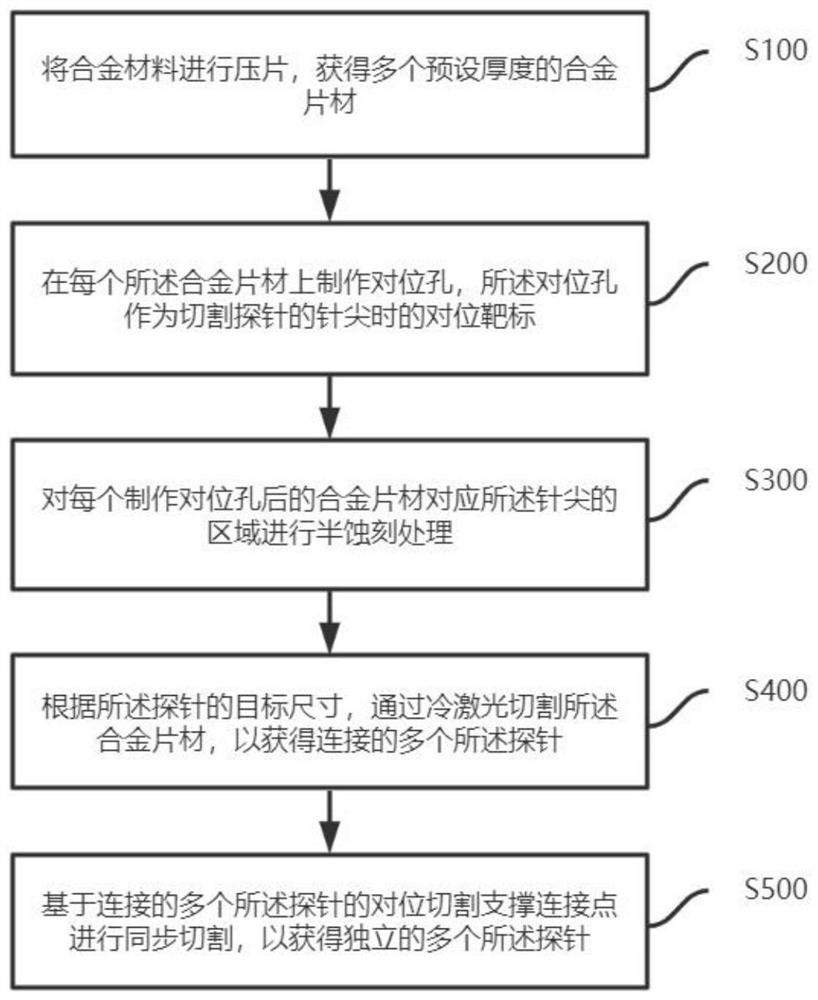

[0087] Based on the above-mentioned embodiment, the parts that are the same as the above-mentioned embodiment in this embodiment will not be repeated one by one. This embodiment provides a method for manufacturing a multi-element alloy probe for semiconductor testing, including steps:

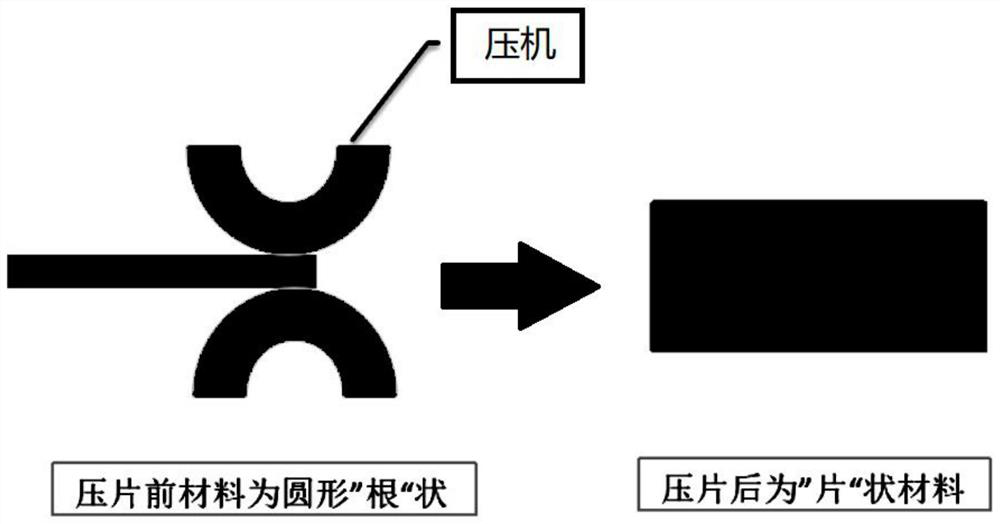

[0088] S100 presses the alloy material into sheets to obtain alloy sheets with multiple preset thicknesses. Exemplary, including steps:

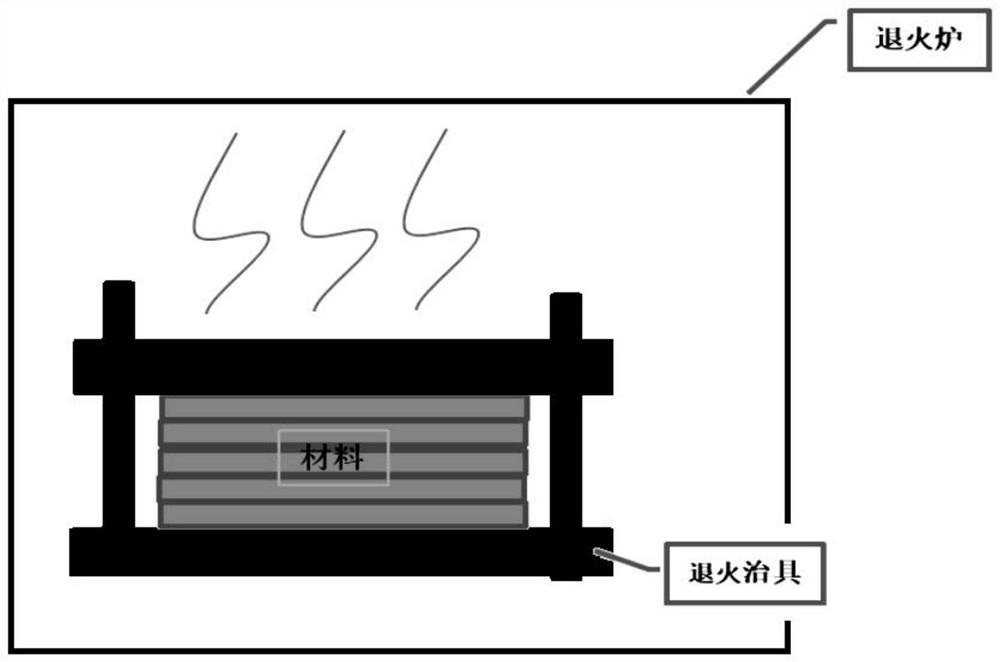

[0089] S01: Use a four-axis metal tablet press to press the copper-silver alloy material with a diameter of 0.3mm. After 4-6 presses, the copper-silver metal sheet with the designed thickness is obtained. The thickness of the alloy sheet is 30-100um, which meets the size requirements of the existing wafer-level chip test probes.

[0090] Among them, the silver content in the copper-silver alloy is 1%-10%, the copper content is 90%-99%, and the tensile strength of the alloy is 400-1500Mpa. This thickness meets the existing wafer-level chip test probe size re...

Embodiment 3

[0147] A multi-element alloy probe for semiconductor testing, comprising: a multi-element alloy probe for semiconductor testing manufactured according to the manufacturing method of the multi-element alloy probe for semiconductor testing.

[0148] Specifically, such as Figure 10 As shown, it can be seen from left to right that the structure of the probe includes: a pointed head with a contact surface smaller than the needle body, an elastic body of the probe, and a needle tail with a limiting function.

[0149] The probe made by the invention has wide adaptability to probe materials, and does not need to be limited by the material limitations of electroforming alloys of traditional MEMS probes. The probe body can be obtained by traditional metallurgical methods, and rare elements can be added to form materials with special performance requirements. . The probe made by the present invention can quickly and accurately make the needle tip of the probe, and the size of the fast ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com