Heat preservation and insulation aluminum profile and preparation method thereof

A technology for thermal insulation and aluminum profiles, applied in the field of aluminum profiles, can solve the problems of long time spent tightening screws, affecting assembly efficiency, etc., and achieve the effect of improving assembly efficiency and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

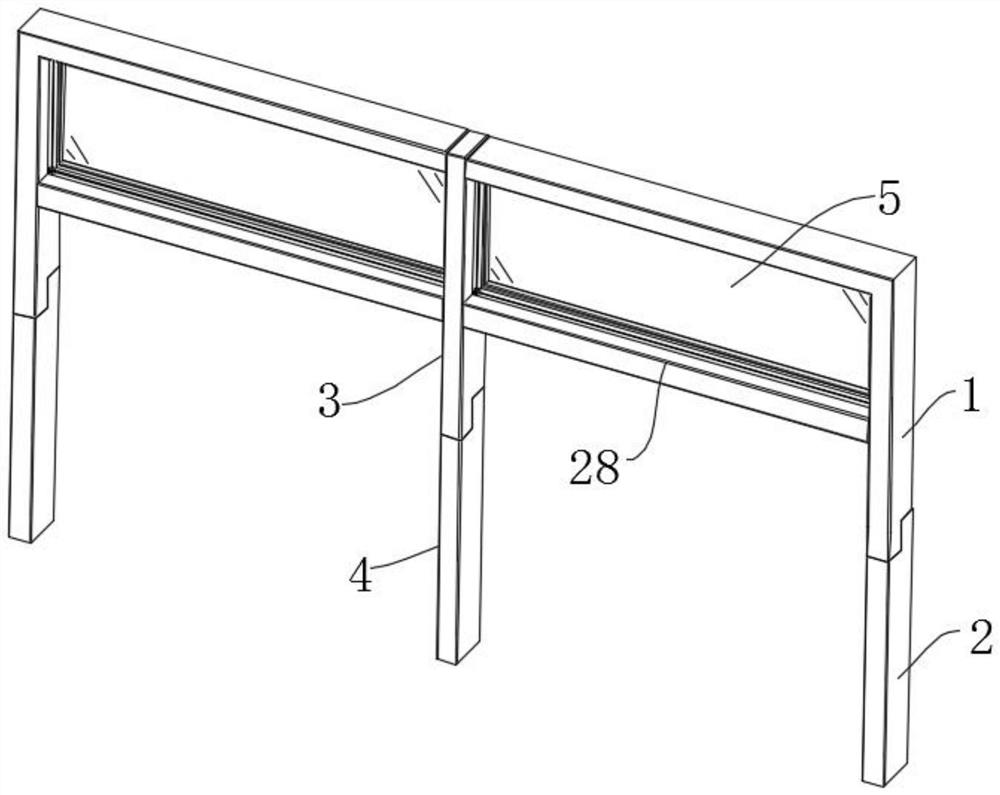

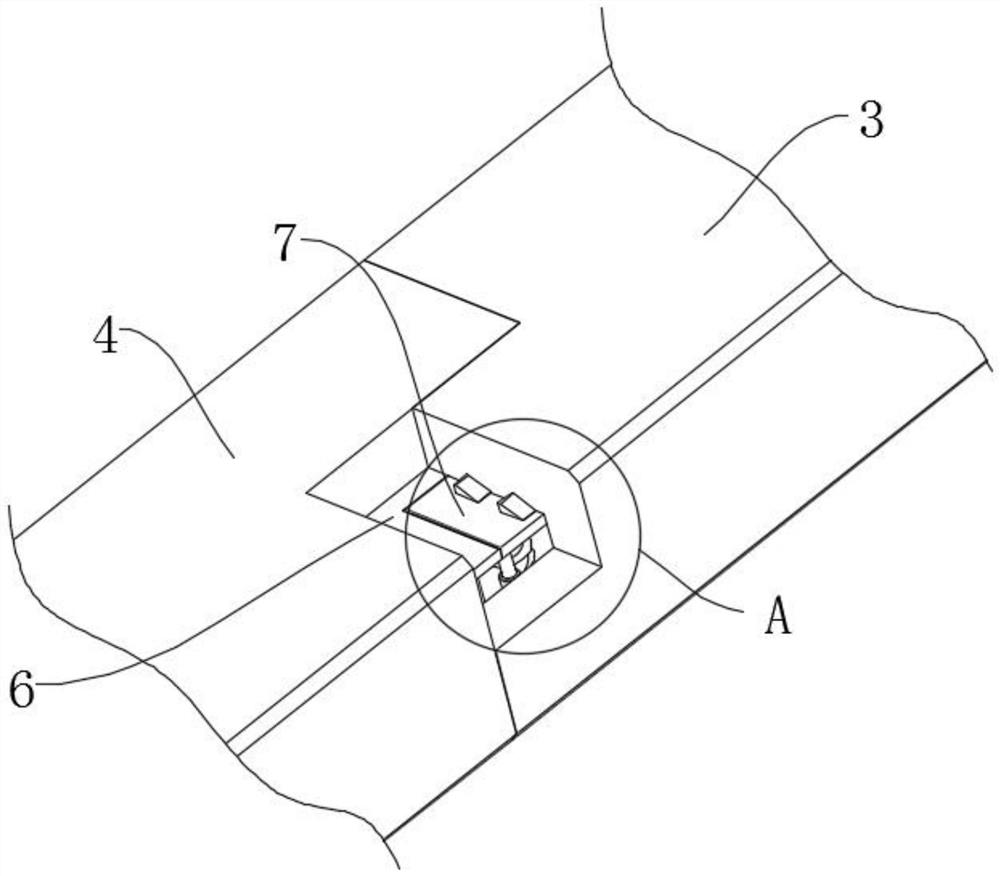

[0032] Such as Figure 1-7As shown, this embodiment proposes a thermal insulation aluminum profile, including a main aluminum frame 1, the lower end surface of the main aluminum frame 1 is fitted with a No. 1 extension frame 2, and the end of the main aluminum frame 1 is fitted and installed There is a connecting aluminum frame 3, and the lower end surface of the connecting aluminum frame 3 is fitted with a No. 2 extension frame 4, between the main aluminum frame 1 and the No. 1 extension frame 2 and between the connecting aluminum frame 3 and the No. 2 extension frame 4 There are clamping parts installed between them, and an aluminum beam 28 is installed between the connecting aluminum frame 3 and the main aluminum frame 1. The aluminum beam 28 plays the role of supporting the installation frame 16. The aluminum beam 28 and the connecting aluminum frame 3 and the main aluminum frame 1 are provided with fixing parts, the side and top surface of the main aluminum frame 1, the s...

Embodiment 2

[0034] The scheme in embodiment 1 is further introduced below in combination with specific working methods, see the following description for details:

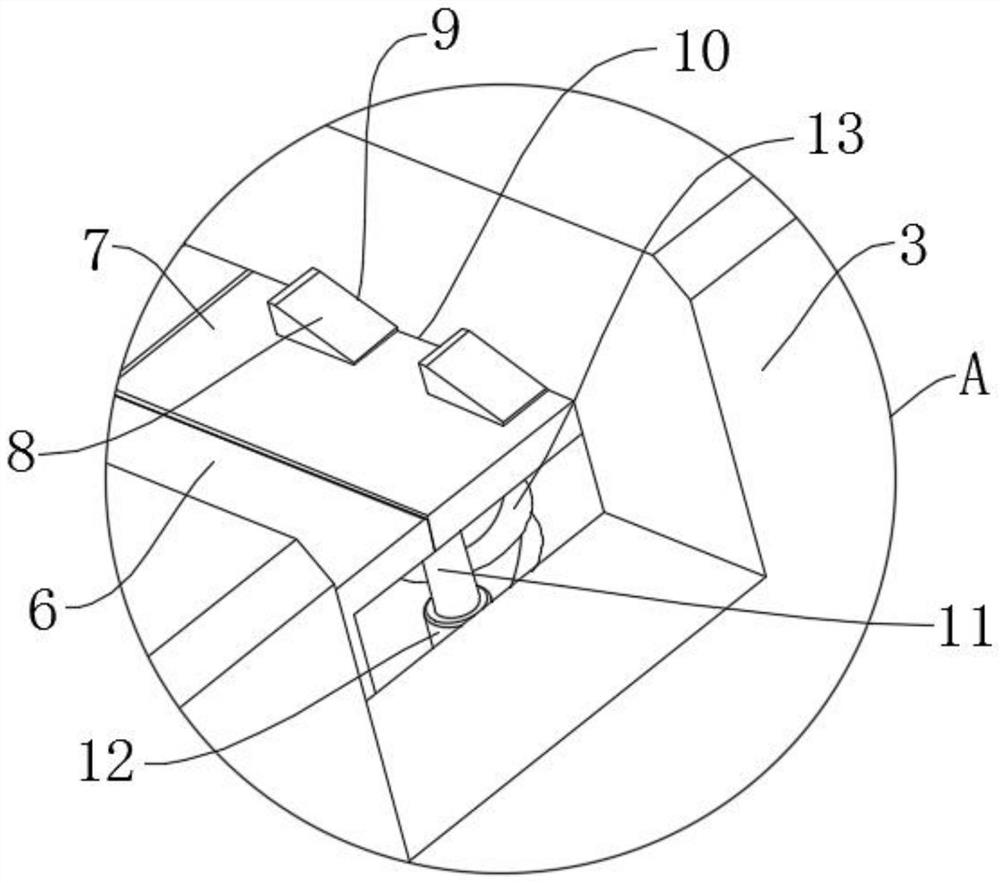

[0035] As a preferred embodiment, on the basis of the above method, further, the clamping part includes a positioning frame 6 extending on the front end of the second extension frame 4 and the front end of the first extension frame 2, and the positioning frame 6 plays a positioning role. Positioning slot 10 is provided at the lower edge of the rear end face of the main aluminum frame 1 and the lower edge of the rear end face of the connecting aluminum frame 3, and the positioning frame 6 fits inside the positioning slot 10, and the positioning slot 10 plays the role of The function of restricting the positioning frame 6 is that the side of the positioning frame 6 fits through and elastically installs a fixing seat 7, and the side of the fixing seat 7 extends with a triangular bump 8, and the triangular bump 8 fits through the i...

Embodiment 3

[0046] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0047] Specifically, when in use, the installation frame 16 is placed in the frame groove 17 on the main aluminum frame 1, and then the clamping column 15 on the connecting aluminum frame 3 is docked with the clamping groove 14 on the main aluminum frame 1 At this time, the installation frame 16 is located in the frame groove 17 on the connecting aluminum frame 3, then the bracket 27 is pressed down, and the aluminum beam 28 is placed between the main aluminum frame 1 and the connecting aluminum frame 3, this When the installation frame 16 is located in the frame groove 17 on the aluminum beam 28, then the bracket 27 is released, so that the bracket 27 resets into the bracket groove 38 on the aluminum beam 28 under the action of the jacking spring 35, and at the same time The limit block 37 on the seat 27 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com