Electric push rod

A technology of electric push rods and screw rods, which is applied in the direction of electric components, electrical components, electromechanical devices, etc. It can solve the problems of difficulty in ensuring the coaxiality of catheters, screw nuts, poor use stability, large welding deformation, etc., and achieve smooth transmission , high installation accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below according to the accompanying drawings and specific embodiments.

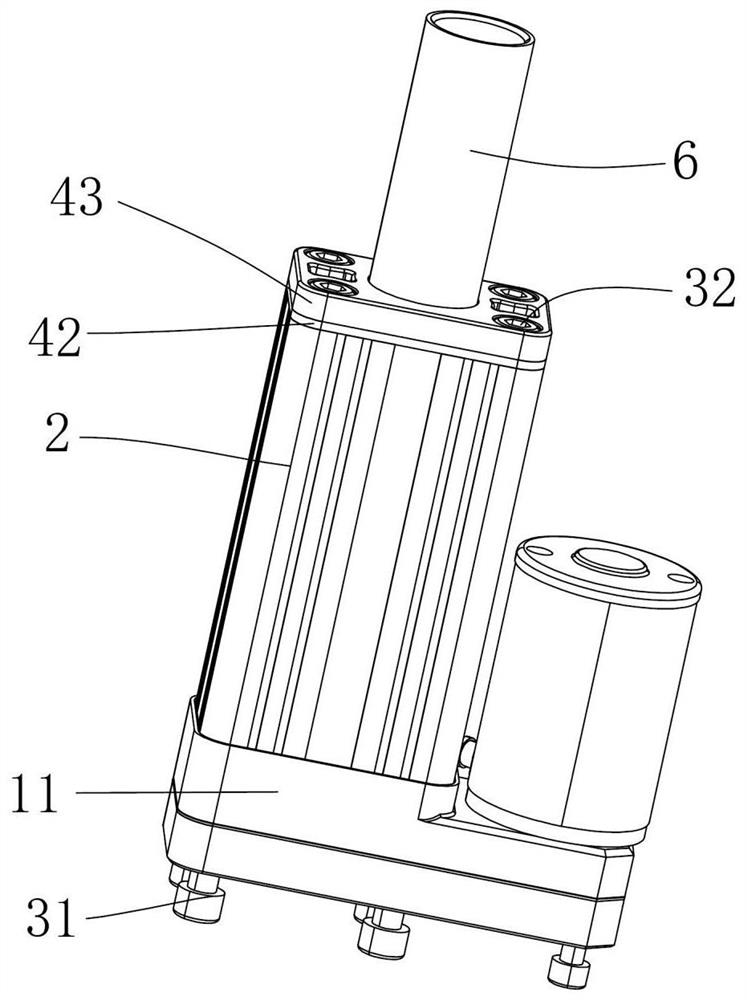

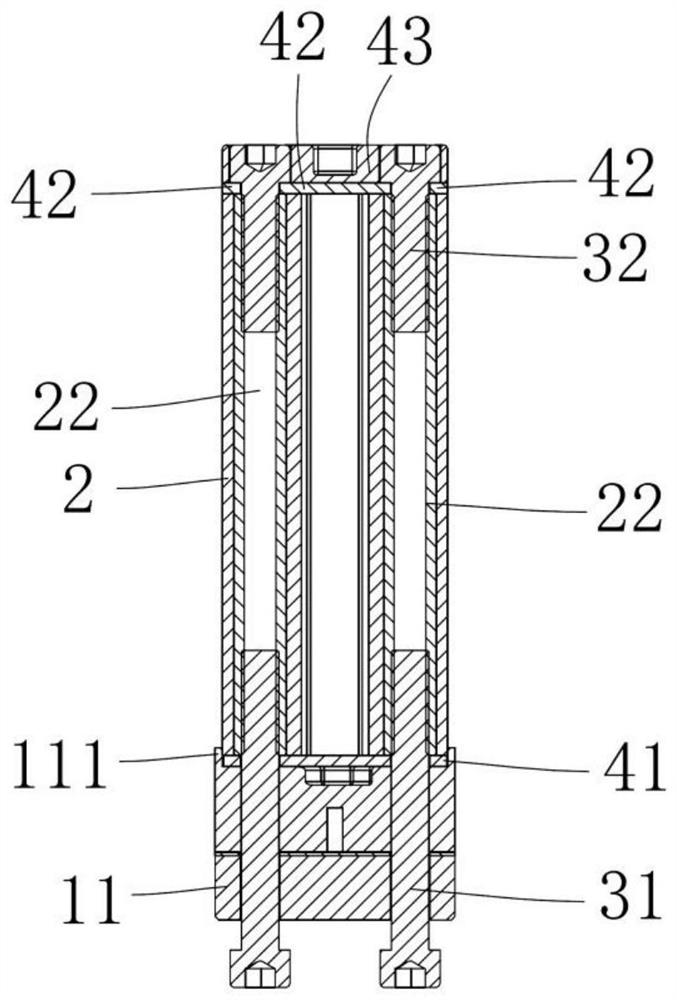

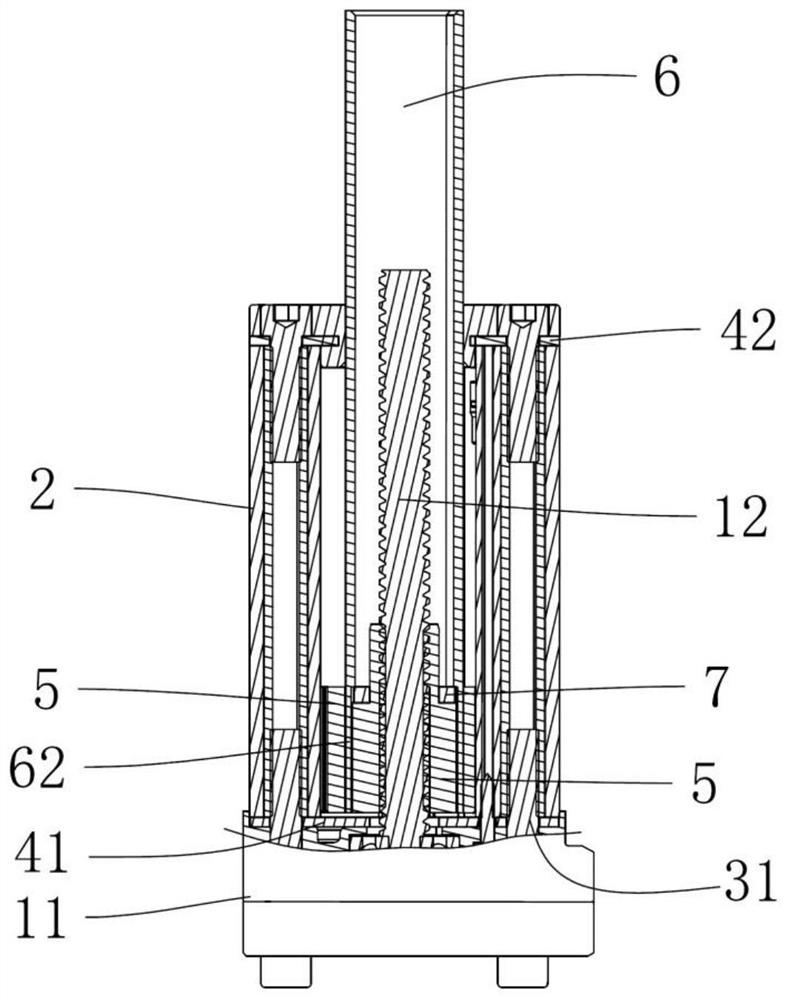

[0033] Depend on Figure 1 to Figure 5 As shown, an electric push rod of the present invention is characterized in that it includes a reduction box 11 and a conduit assembly fixed outside the reduction box 11. The conduit assembly includes a conduit body 2. The four corners of the conduit body 2 are respectively provided with a And through the fixing holes 21 at both ends, the fixing holes 21 are excessively equipped with a reinforcing tube 22, the hardness of the reinforcing tube 22 is greater than the hardness of the catheter body 2, and the two ends of the reinforcing tube 22 are respectively located in the two ends of the fixing hole 21, and the length of the reinforcing tube 22 is the same as The fixing holes 22 have the same length, and there is glue between the reinforcing pipe 22 and the inner wall of the fixing hole 21 . Wherein, the conduit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com