Combined micro-pump control device

A technology of a control device and a micro-pump, which is applied in the directions of hypodermic injection devices, devices introduced into the body, and devices for drugs, etc., can solve the problem that the drugs that cannot be mixed well, have no flushing function, and cannot be injected can be maintained at the required level. temperature and other issues, to achieve the effect of solving the more stringent requirements of storage environment temperature and ensuring the efficacy of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

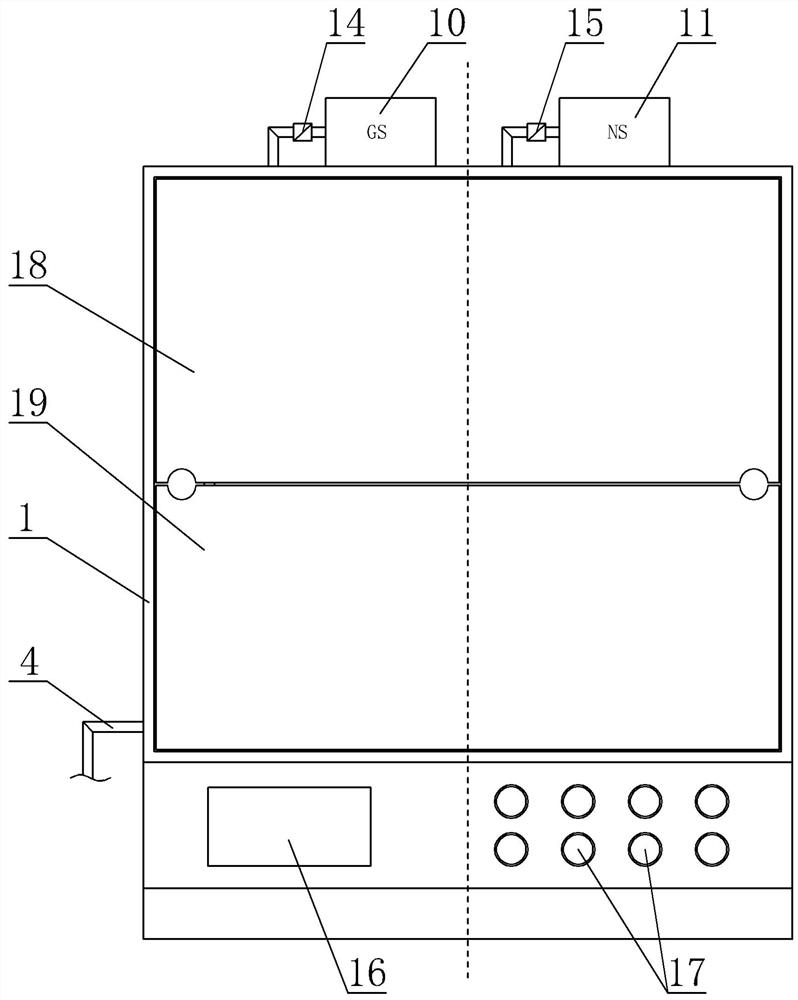

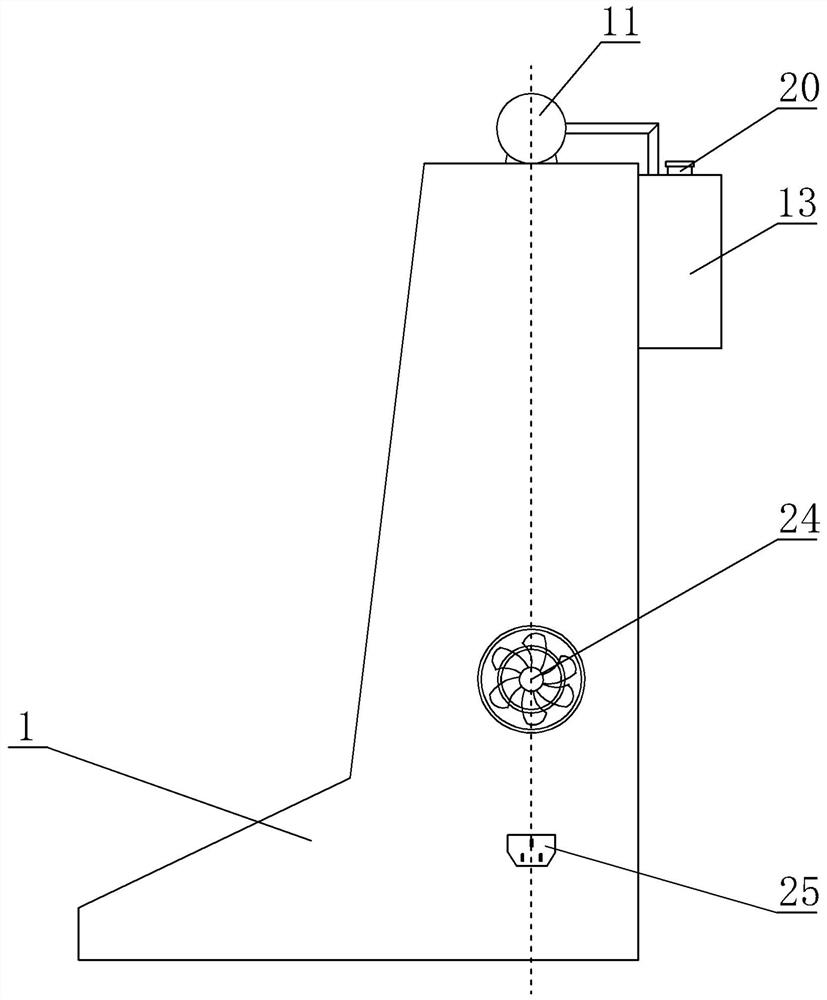

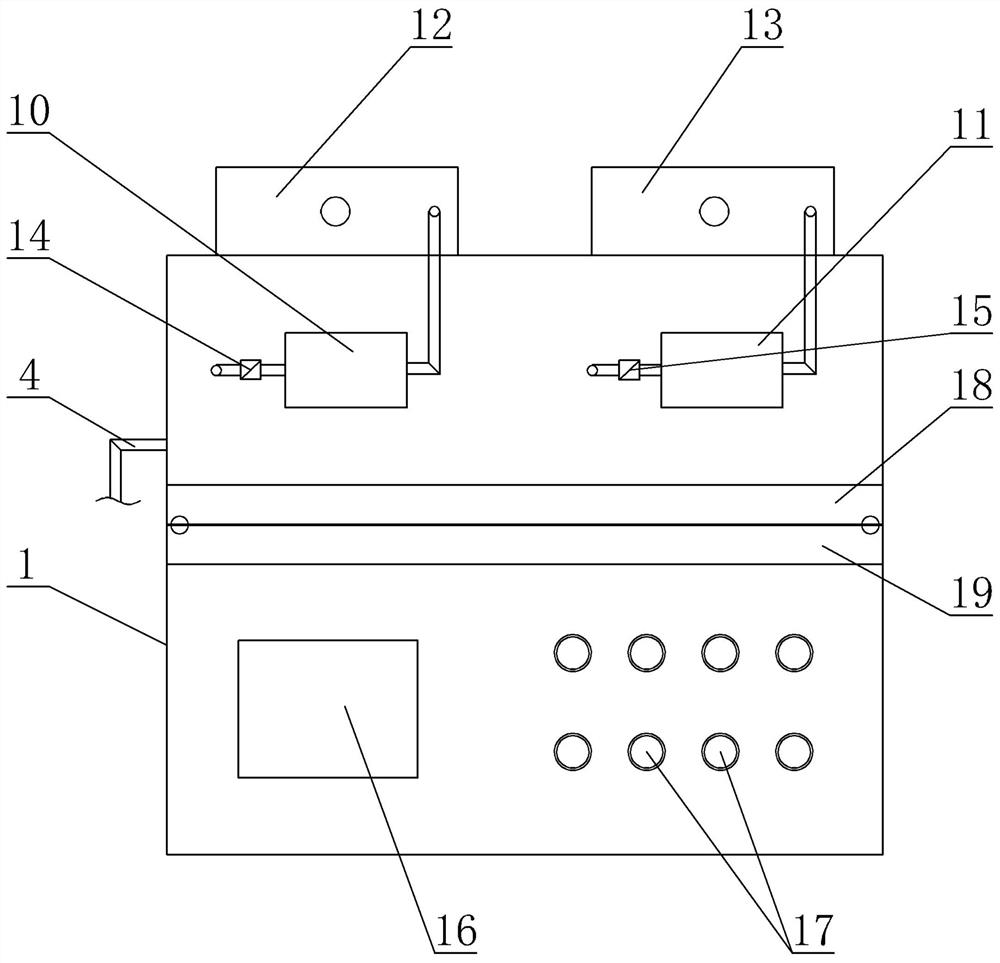

[0020] Such as figure 1 , figure 2 with image 3 As shown, the front view, right view and top view of the combined micropump control device of the present invention are respectively given, Figure 4 The front view of the upper cover and the lower cover of the combined micropump control device of the present invention using the perspective drawing method is given, Figure 5 The front view of the upper cover and the lower cover of the combined micropump control device of the present invention using the perspective drawing method is given, Image 6 The circuit principle diagram of the circuit part in the present invention is given, the combined micropump control device shown is composed of a housing 1, an injection main pipe 4, a plurality of microinjection devices, a saline flushing pump 10, a sugar water flushing pump 11, and a saline container 12 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com