Preparation method of crotonic acid

A technology of crotonic acid and crotonaldehyde, applied in the field of preparation of crotonic acid, can solve the problems of large damage to the environment and operators, unfavorable recovery and waste liquid treatment, and high cost of precious metal catalysis, and achieves low cost, guaranteed oxidation, and improved conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

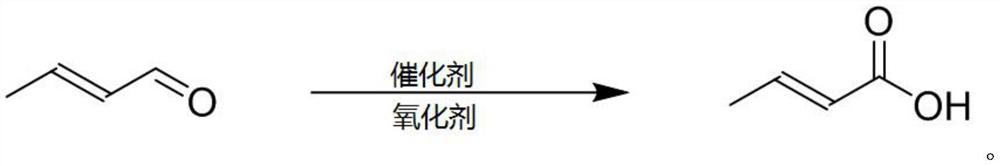

[0023] The invention provides a preparation method of crotonic acid, comprising the following steps:

[0024] In the presence of molecular sieve catalyst, crotonaldehyde, organic solvent and oxidizing gas are mixed to carry out catalytic oxidation reaction to obtain crotonic acid.

[0025] In the present invention, the molecular sieve catalyst is preferably 3A molecular sieve, 4A molecular sieve, 5A molecular sieve, NKF-5-80W molecular sieve, NKF-6-25 molecular sieve, NKF-7SC molecular sieve, ZSM-5-50 molecular sieve, NKF-50- One or more of 25 molecular sieve and NKF-8SC0.8 molecular sieve. In the present invention, the particle size of the molecular sieve catalyst is preferably 80-100 mesh. In the present invention, the molecular sieve is an aluminosilicate compound with a cubic lattice, which has a uniform microporous structure, a uniform pore diameter, and has the advantages of strong adsorption capacity and good thermal stability. During the oxidation of crotonaldehyde t...

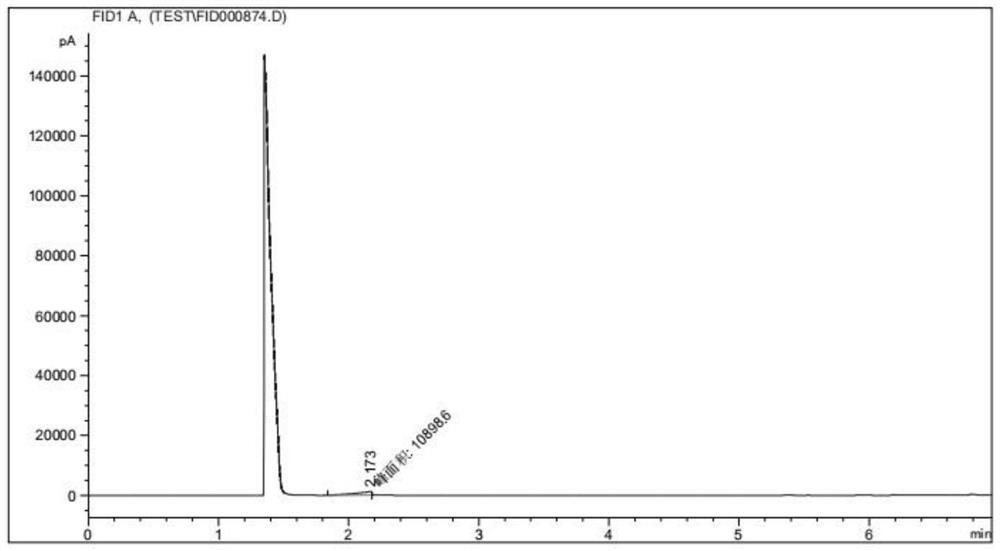

Embodiment 1

[0047]Taking crotonaldehyde as a raw material, 3A molecular sieve as a catalyst, weighing crotonaldehyde and molecular sieve according to a weight ratio of 1:0.1, the crotonaldehyde quality is 1kg, and crotonaldehyde and molecular sieve are added in ethyl acetate to obtain a mixed solution, the crotonaldehyde The mass volume ratio of aldehyde and ethyl acetate is 1:5, and the mixed solution is uniformly mixed on a magnetic stirrer with a rotating speed of 400 rpm / min; air is fed into the mixed solution, and the reaction temperature is 30 ° C, and the pressure is The crude crotonic acid was obtained by catalytic oxidation reaction at 0.1MPa for 12h.

[0048] The crude crotonic acid product was evaporated at 80°C, the unconverted crotonaldehyde was recovered, and then a solvent was added for filtration to obtain a filtrate of the crude crotonic acid product and a solid catalyst; the filtrate was crystallized by cooling at 5°C, filtered, and dried to obtain a refined Crotonic aci...

Embodiment 2

[0053] Taking crotonaldehyde as a raw material, 5A molecular sieve as a catalyst, weighing crotonaldehyde and molecular sieve according to a weight ratio of 1:0.3, the crotonaldehyde quality is 10kg, and crotonaldehyde and molecular sieve are added in n-pentane to obtain a mixed solution, the crotonaldehyde The mass volume ratio of aldehyde and n-pentane is 1:5, and the mixed solution is uniformly mixed on a magnetic stirrer with a rotating speed of 500 rpm / min; Ozone is introduced into the mixed solution, and the reaction temperature is 35 ° C and the pressure is 0.5 The crotonic acid crude product was obtained by catalytic oxidation reaction under MPa for 24 h; the crotonic acid crude product was evaporated at 60 ° C, the unconverted crotonaldehyde was recovered, and then a solvent was added for filtration to obtain the crotonic acid crude product filtrate and solid catalyst; Cooling and crystallization at 5 °C, filtering, and drying to obtain refined crotonic acid; after dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap