Metal prefabricated pavement slab structure and prefabricated pavement

A board structure and metal technology, applied to roads, roads, special pavements, etc., can solve the problems of inability to recycle and reuse, low stability, etc., and achieve the effect of improving construction and repair efficiency, light weight, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

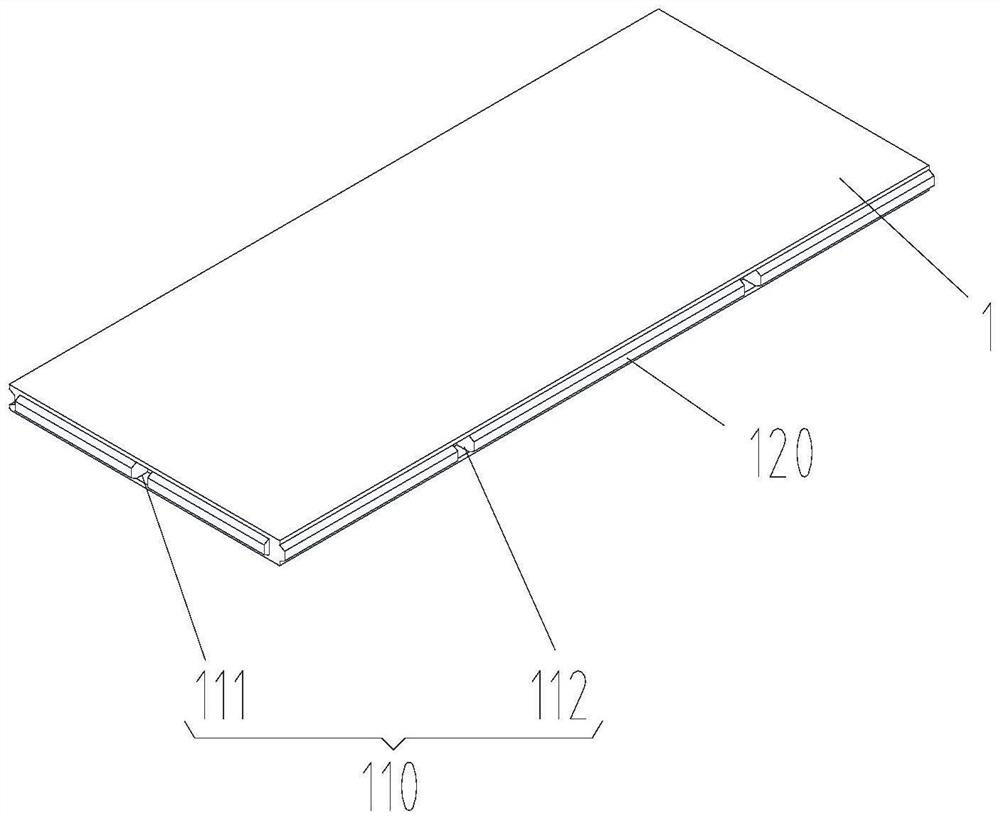

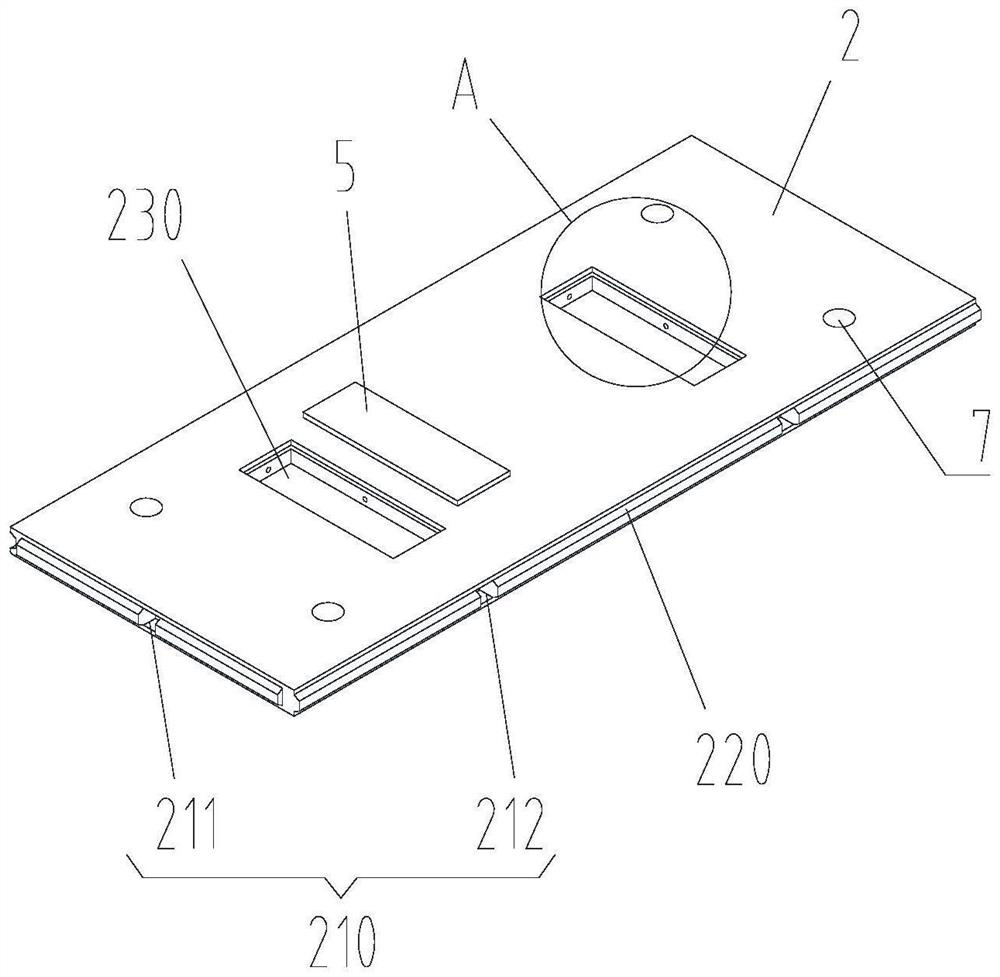

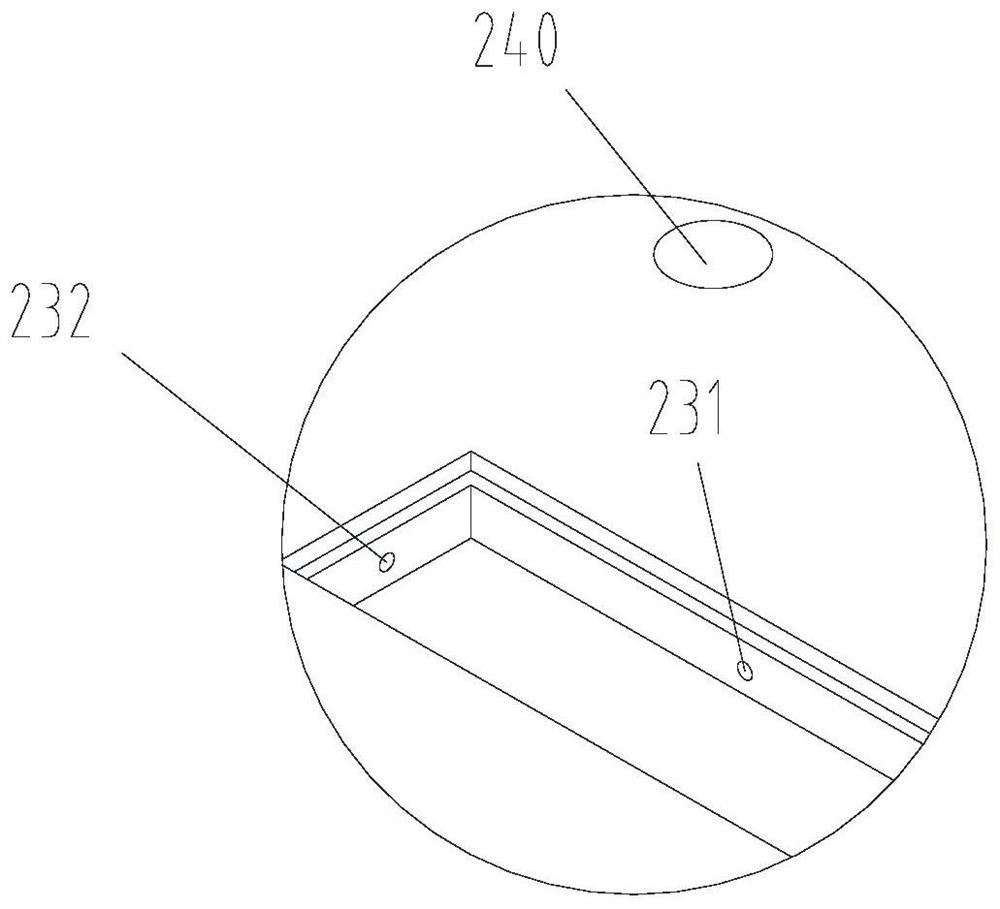

[0032] Such as Figure 1-Figure 3As shown, a metal prefabricated path panel structure provided by the embodiment of the present invention includes a first plate body 1 and a second plate body 2 made of metal materials that can be spliced with each other; The first channel 110 of a plate body 1, the edge of the first plate body 1 is provided with a first groove 120; the second plate body 2 is provided with a second channel corresponding to the first channel 110 and extending in the same direction Hole 210, the edge of the second plate 2 is provided with a second rebate 220 that matches the first rebate 120; the upper side of the second plate 2 is provided with an anchor reserved groove for loading the anchor 3 230 , the second hole 210 passes through the anchor reserved groove 230 , so that the second hole 210 forms a perforation on the side wall of the anchor reserved groove 230 . Both the above-mentioned first plate body 1 and the second plate body 2 are made of metal mate...

Embodiment 2

[0034] Such as Figure 4 , different from Embodiment 2, the first hole 110 and the second hole 210 in this embodiment are arranged along the width direction of the first board body 1 or the second board body 2, that is, they are all longitudinally arranged correspondingly, but the first The plate body 1 is also provided with a first left oblique tunnel 113 and / or a first right oblique tunnel 114 . When the first left oblique tunnel 113 and the first right oblique tunnel 114 are both provided, the first left oblique tunnel 113 and the first right oblique tunnel 114 intersect, and the staggered stretching of this oblique direction can improve the local plate body Excellent interlocking performance, improve local integrity, and can effectively absorb and buffer omnidirectional impact loads.

Embodiment 3

[0036] refer to Figure 1 to Figure 3 , the difference from Embodiment 1 or 2 is that the above-mentioned first tunnel 110 includes a first transverse tunnel 111 and a first longitudinal tunnel 112 . The first transverse hole 111 extends along the length direction of the first plate 1 ; the first longitudinal hole 112 extends along the width of the first plate 1 . The second tunnel 210 includes a second transverse tunnel 211 and a second vertical tunnel 212 . The second transverse hole 211 extends along the length direction of the second plate body 2 ; the second longitudinal hole 212 extends along the width direction of the second plate body 2 . The first transverse hole 111 is parallel to the second transverse hole 211 ; the first longitudinal hole 112 corresponds to the second longitudinal hole 212 . The first transverse tunnel 111, the first longitudinal tunnel 112, the second transverse tunnel 211 and the second longitudinal tunnel 212 are arranged in this way, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com