Hydraulic wheel cylinder allowing manual and automatic integrated adjusting of brake clearance

A brake clearance, integrated technology, applied in the direction of brake type, brake actuator, slack adjuster, etc., can solve the problem that the shoe cannot be retracted to increase the brake gap, cannot be adjusted in time, and manual adjustment is impossible at any time. To achieve the effect of convenient manual adjustment and automatic double adjustment and locking, avoid brake drag and lock failure, and facilitate manual adjustment of self-locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

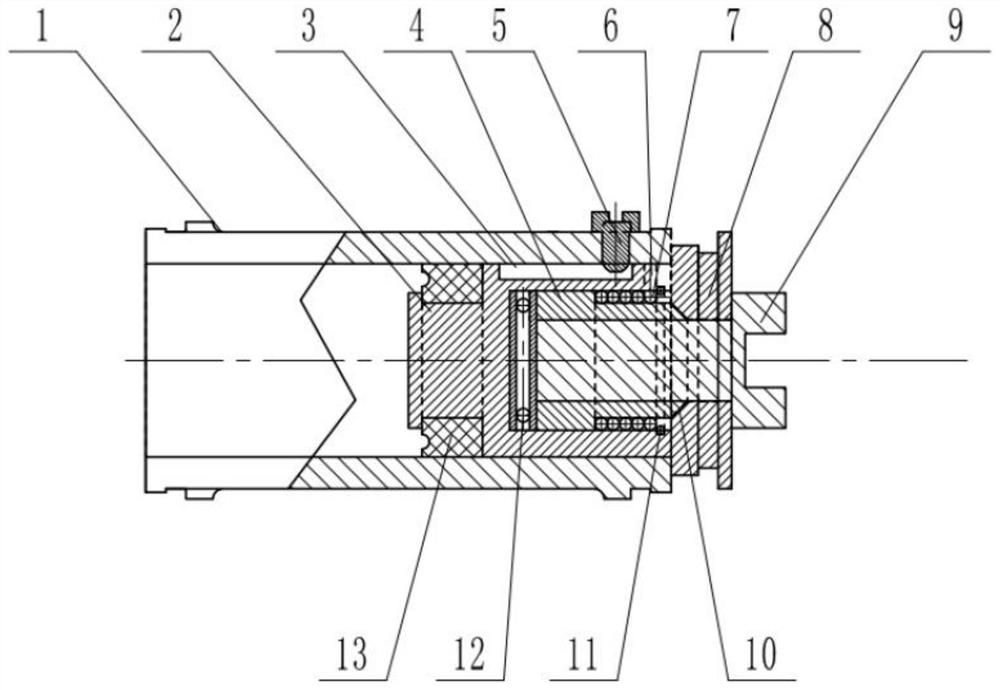

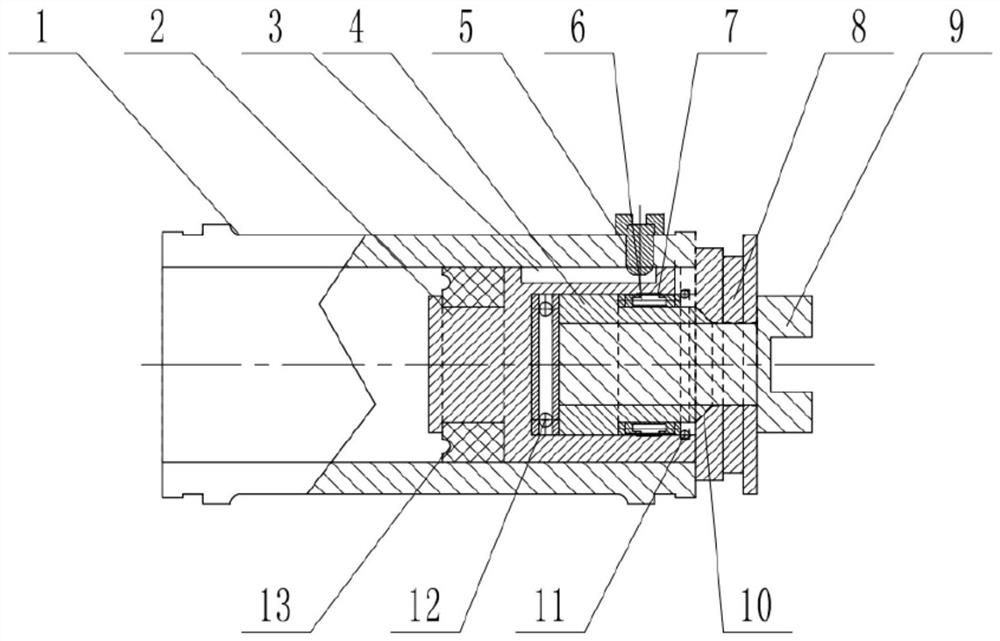

[0023] see figure 1 and figure 2 In this embodiment, the hydraulic wheel cylinder for adjusting the braking clearance manually has a cylinder body 1, and a piston 2 is arranged in the cylinder body 1, and a center hole is arranged in the center of the piston 2, and a bolt 9 is arranged in the center hole, and the bolt 9 The outer end forms a protrusion at the end of the cylinder body 1 and is provided with an end surface engaging groove.

[0024] Such as figure 1 As shown, in the present embodiment, a helical groove 3 is provided on the outer peripheral surface of the piston 2, and a pin 5 that penetrates the cylinder 1 radially from the outside is inserted in the helical groove 3, and the pin 5 and the helical groove 3 are inserted into the helical groove 3. There is an axial movable gap between the grooves 3 .

[0025] The inner cavity of the piston 2 is provided with a clutch sleeve 4, and the central hole used to configure the bolt 9 is the central hole of the clutch s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com