Low-friction efficient driving wheel gear ring and implementation method thereof

A low-friction, gear ring technology, applied to engine components, engine lubrication, components with teeth, etc., can solve the problems that the friction coefficient cannot be reduced, the power loss cannot be improved, and the wear-reducing effect is limited, so as to improve the overall Vehicle maneuverability, low friction coefficient, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

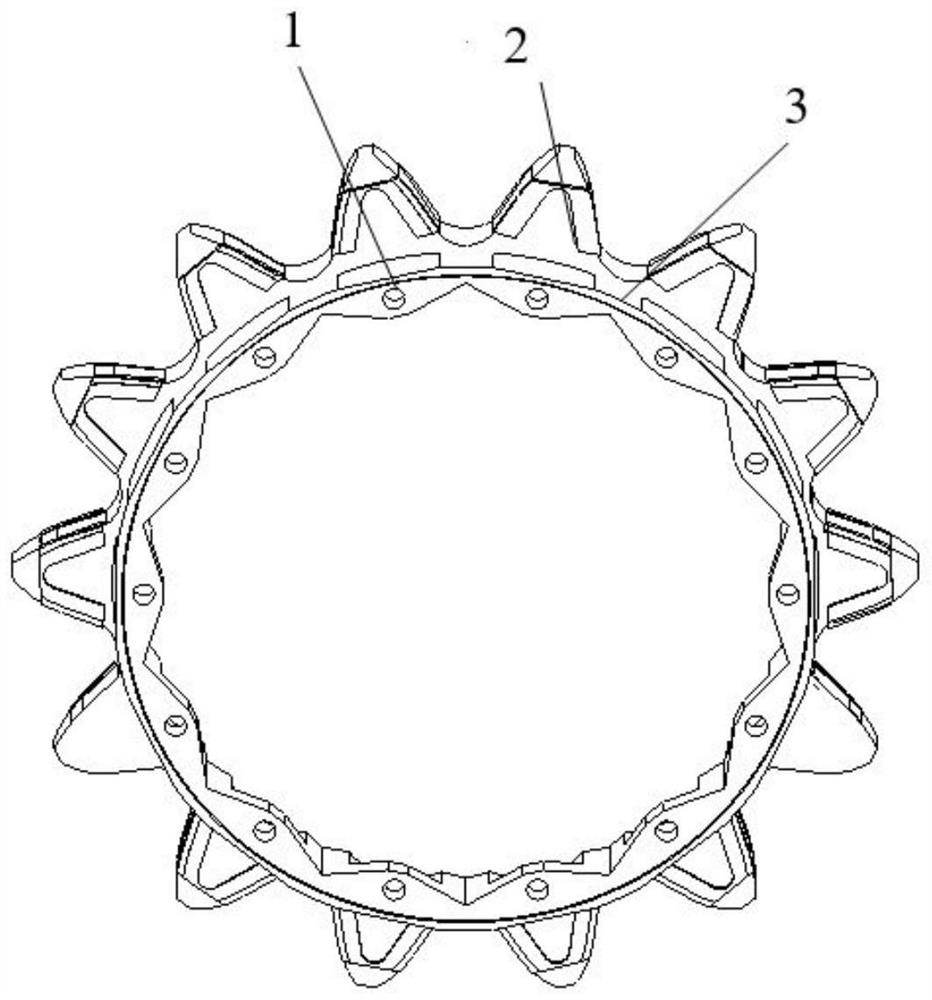

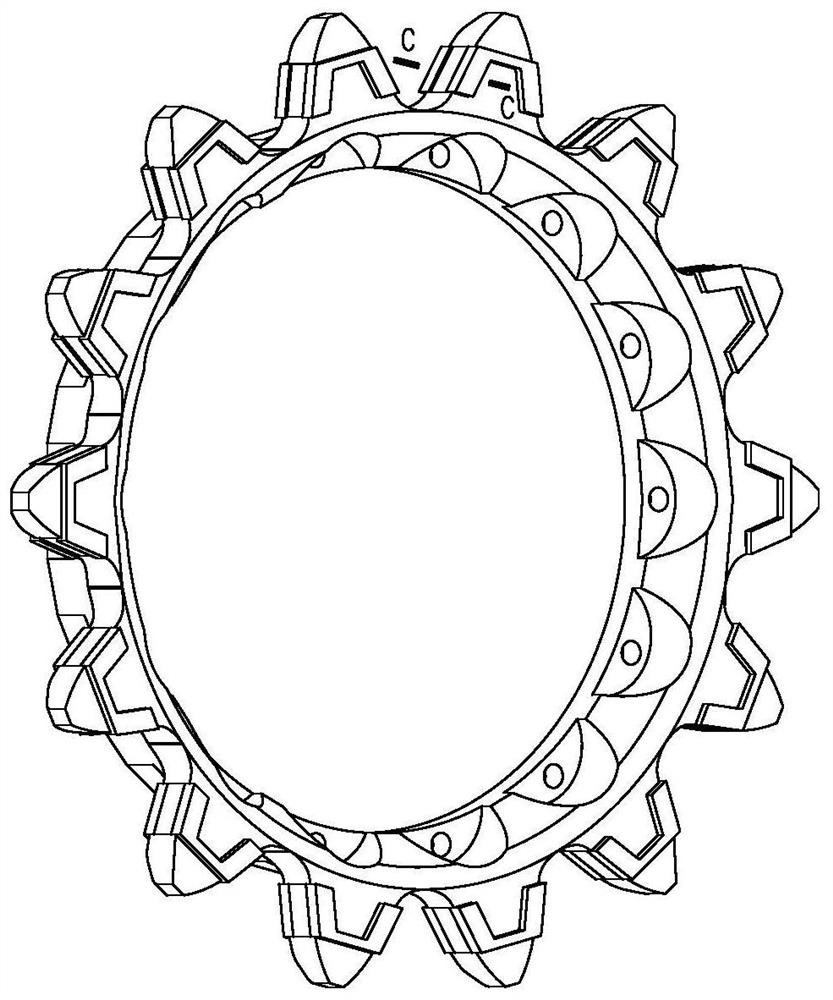

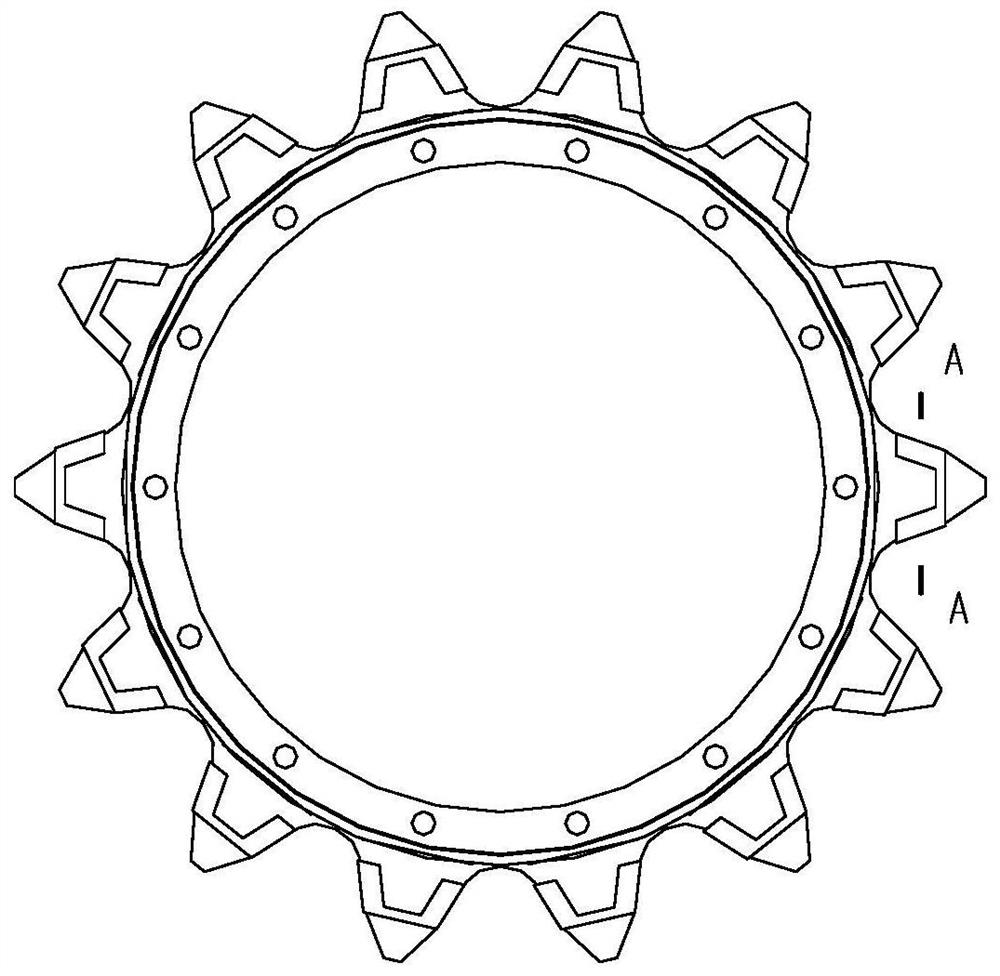

[0033] Attached below Figure 1 to Figure 6 The present invention is described in further detail.

[0034] see Figures 1 to 3 , a low-friction high-efficiency drive wheel ring gear mainly consists of a ring gear base 1, a self-lubricating friction-reducing block 2 and a limit baffle 3. The shape of the self-lubricating anti-friction block 2 is matched with the driving tooth structure on the ring gear base to form a close fit.

[0035] The base body of the driving wheel ring gear adopts steel structure for installation and torque transmission. Grooves for installing the self-lubricating anti-friction block 2 are machined on both sides of the drive tooth structure of the ring gear base 1, and the depth is consistent with the height of the self-lubricating anti-friction block 2 to ensure a smooth streamline after installation. The anti-friction block has the characteristics of low friction coefficient and wear resistance, which can reduce the friction coefficient and wear spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com