Screw rods for PIN-type three-screw extruder

A three-screw and extruder technology, which is applied in the field of screw structure, can solve the problems of affecting the performance of finished materials, the performance of finished materials, the shortening of molecular chains, etc., and achieve the effect of strengthening, improving and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

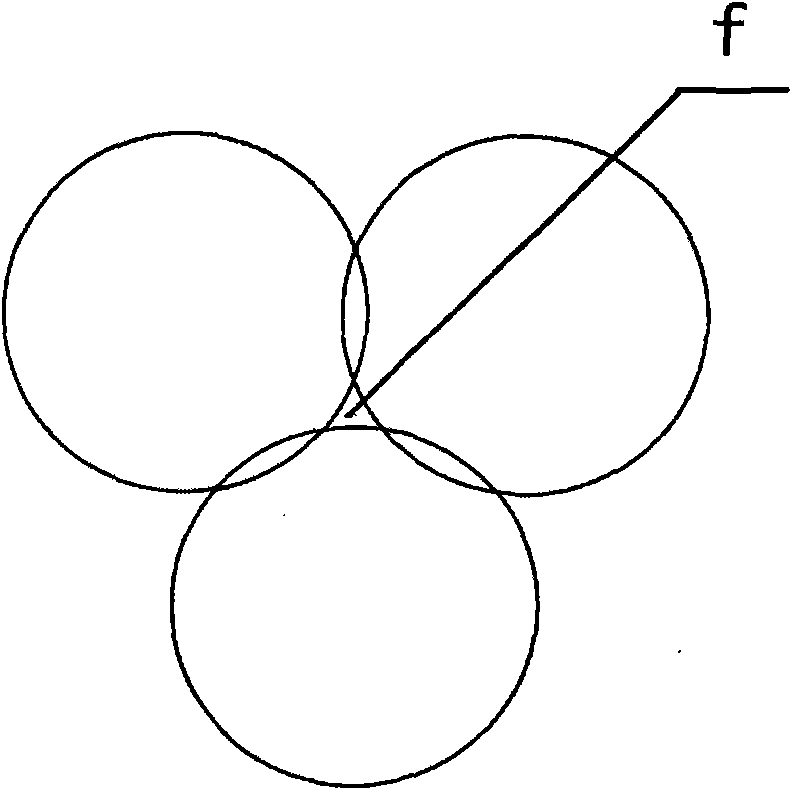

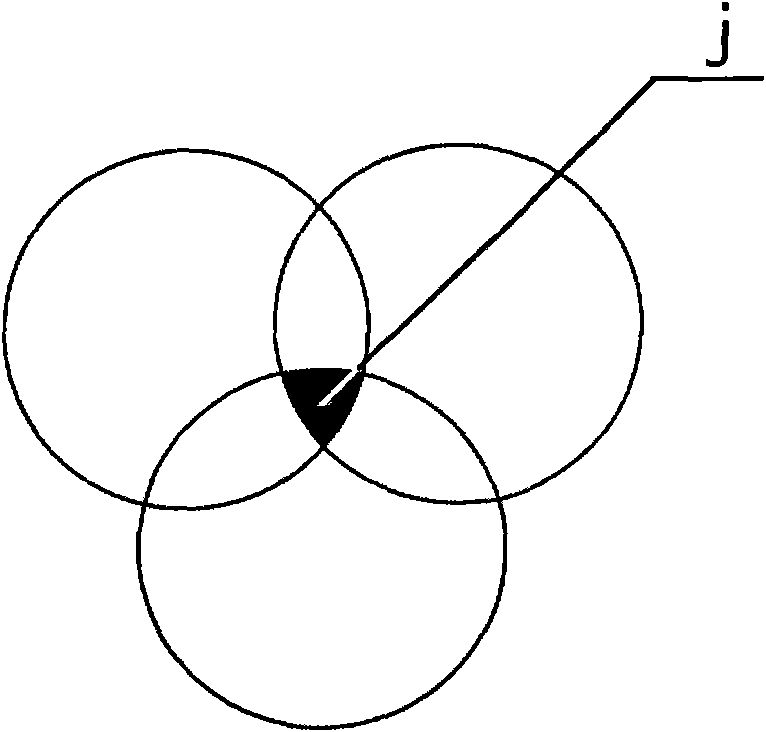

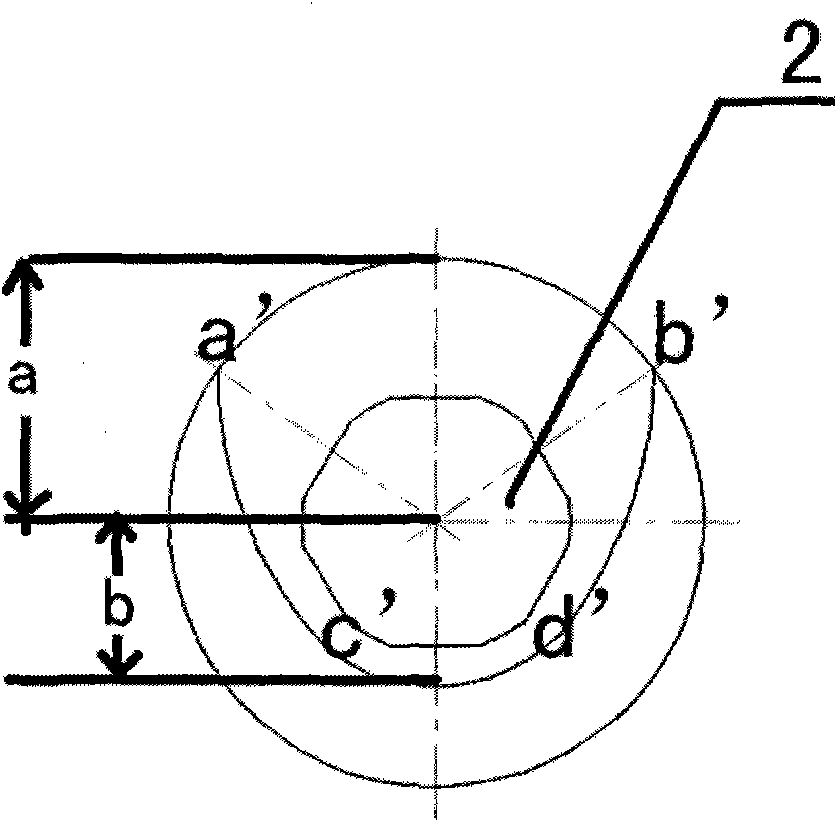

[0035] Depend on image 3 , Figure 4 As can be seen from the illustration, the screw used in the pin-shaped three-screw extruder of this embodiment is composed of a screw mandrel 2 and a threaded element 1 set on the screw mandrel 2, and the threaded elements 1 of the three screws are conjugate Engagement, and the shape of the threaded elements 1 that engage with each other is the same, the outer circle radius formed by the rotation of the threaded element 1 is a=3.0cm, the inner circle radius is b=2cm, and the center distance of the three screws is 5cm. The threaded element 1 is a single-line helical block, which is formed by rotating a single-line helical piece 3 with a certain thickness with the axis of the screw mandrel 2 as the center line. , the inner circle arc c'd' and the transition line a'c' and b'd' connecting the outer circle arc a'b' and the inner circle arc c'd', and the transition line a' c' and b'd' are arranged symmetrically.

[0036] Depend on Figure 5 ...

Embodiment 2

[0039] Depend on Figure 6 , Figure 7 It can be seen that the difference from Embodiment 1 is that the threaded element 1 is a single-wire engagement block, which is formed by rotating a plurality (seven in this embodiment) of single-wire engagement pieces 4 with a certain thickness. The shape of the end face of the engagement piece 4 is identical to that of the single-wire helical piece 3 in Embodiment 1, that is, the end surface of the single-line engagement piece is surrounded by an outer circular arc, an inner circular arc, and a transition line connected between the outer circular arc and the inner circular arc. , and the transition line is set symmetrically. At this time, the same straight line where the radius of the outer circle arc and the radius of the inner circle arc is set as the rotation reference line m, the single-line engagement piece takes the axis of the screw mandrel as the center line of rotation, and each single-line engagement piece is engaged with the...

Embodiment 3

[0041] Depend on Figure 8 , Figure 9It can be seen that the difference from Embodiment 1 is that the threaded element 1 is an equilateral three-wire eccentric engagement block, and the equilateral three-wire eccentric engagement block is composed of a plurality of (this embodiment is 5) equilateral three-wire eccentric engagement blocks with a certain thickness. The meshing piece 5 is rotated, and the shape of the end surface of the equilateral three-line eccentric meshing piece 5 has three corner points, and the corner points are connected by the same transition line, and one of the corner points is used as a point forming the outer circle track of the rotary block. The distance from the point extending from the axis to the transition line is equal to a+b, and the straight line where the distance is located is defined as the reference line of rotation. The equilateral three-line eccentric engagement piece takes the axis of the screw mandrel as the rotation center line, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com