Dual-motor synchronous driving device

A technology of synchronous drive and motor drive, which is applied to the transmission device, transmission device parts, gear transmission device, etc., can solve the problems of long transmission chain, complex structure, failure to obtain practical production application, etc., and achieve the goal of avoiding the interference of gear meshing movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below according to the accompanying drawings.

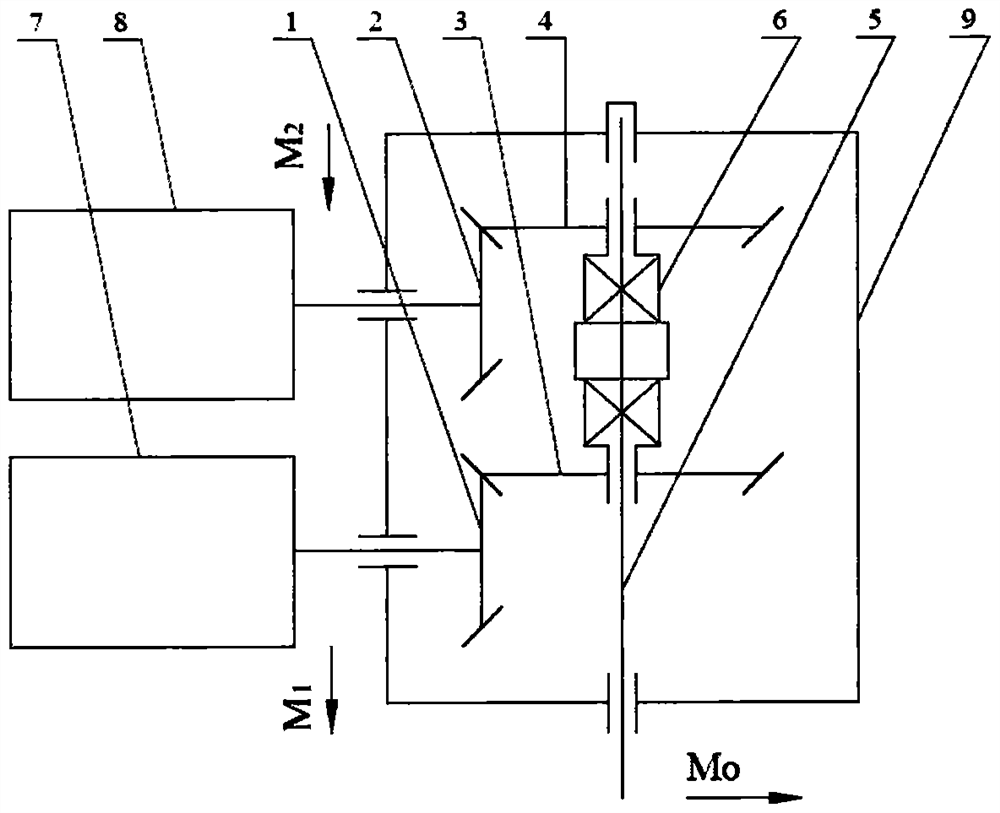

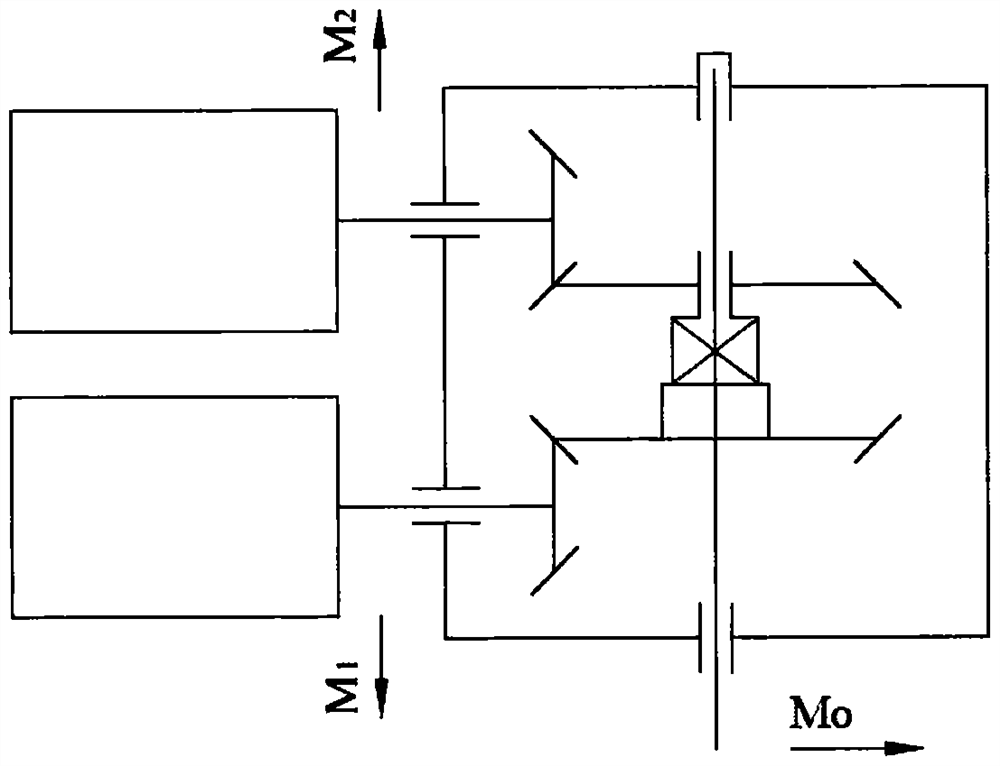

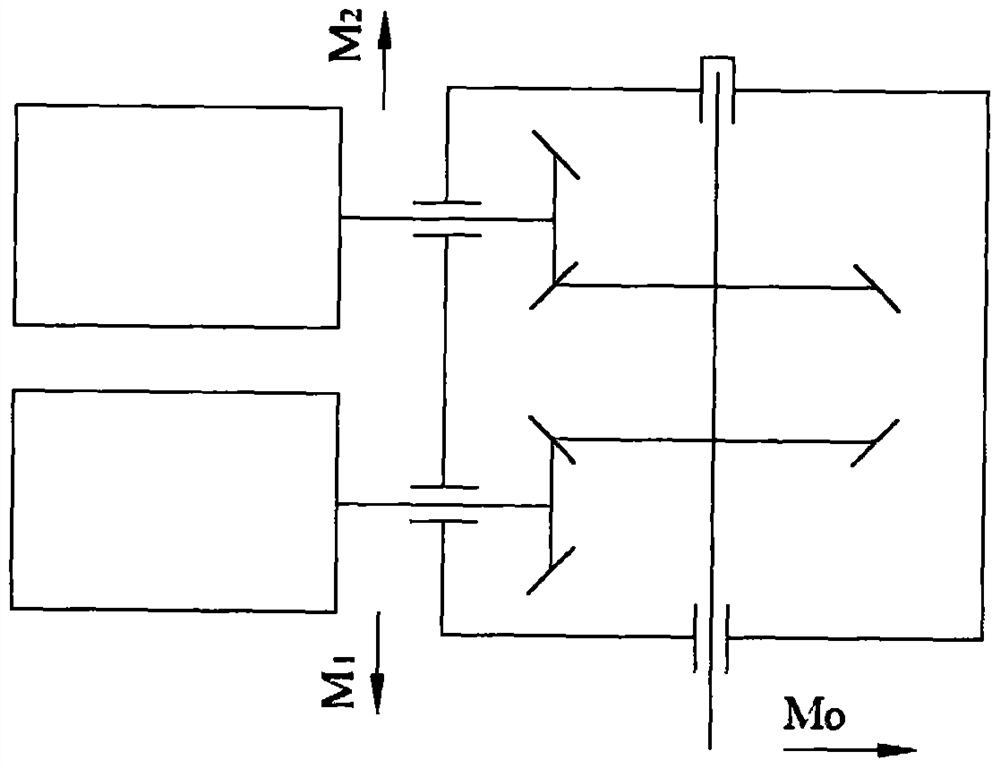

[0025] figure 1 The schematic diagram of the dual-motor synchronous driving device is shown, the dual-motor synchronous driving device includes: the third gear (3) is coaxially connected with the transmission shaft (5), and the elastic element (6) constrains the third gear (3) and the transmission shaft (5). The relative rotation of the shaft (5) and the torque transmission from the third gear (3) to the transmission shaft (5), the fourth gear (4) and the coaxial rotation connection of the transmission shaft (5), another elastic element (6 ) constrains the relative rotation between the fourth gear (4) and the transmission shaft (5), and maintains the torque transmission from the fourth gear (4) to the transmission shaft (5), and the transmission shaft (5) rotates on the transmission box (9) connection and output torque, the first gear (1) is rotated and connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com