Method and device for producing concrete pile

A technology of concrete piles and manufacturing methods, which is applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve problems such as deformation, insufficient drainage, and difficult dimensional accuracy of forming concrete piles, and achieve the effect of low noise and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. The following is one embodiment of the present invention and does not limit the present invention.

[0041] [Outline of Embodiment 1]

[0042] (device structure)

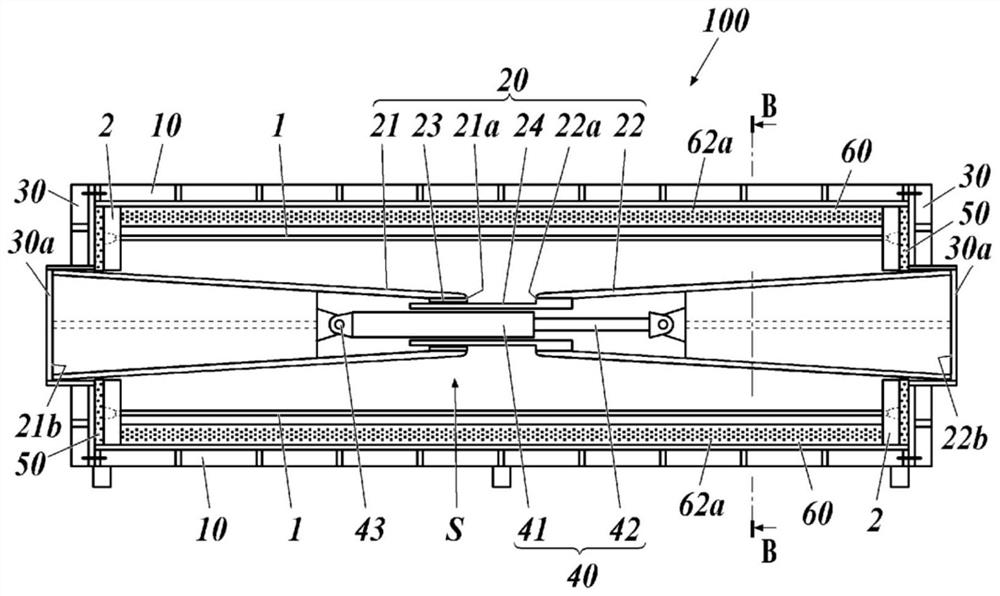

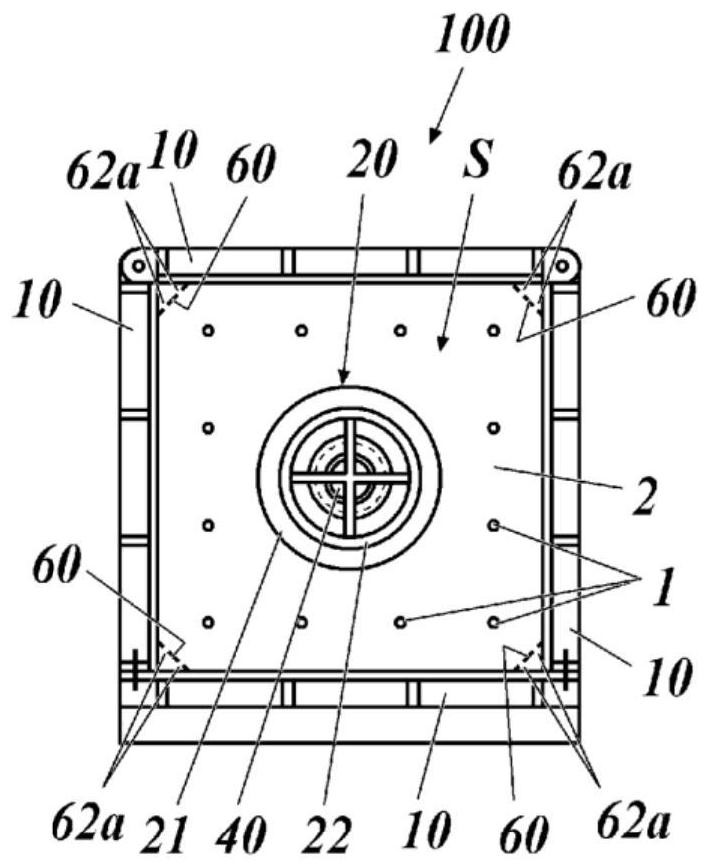

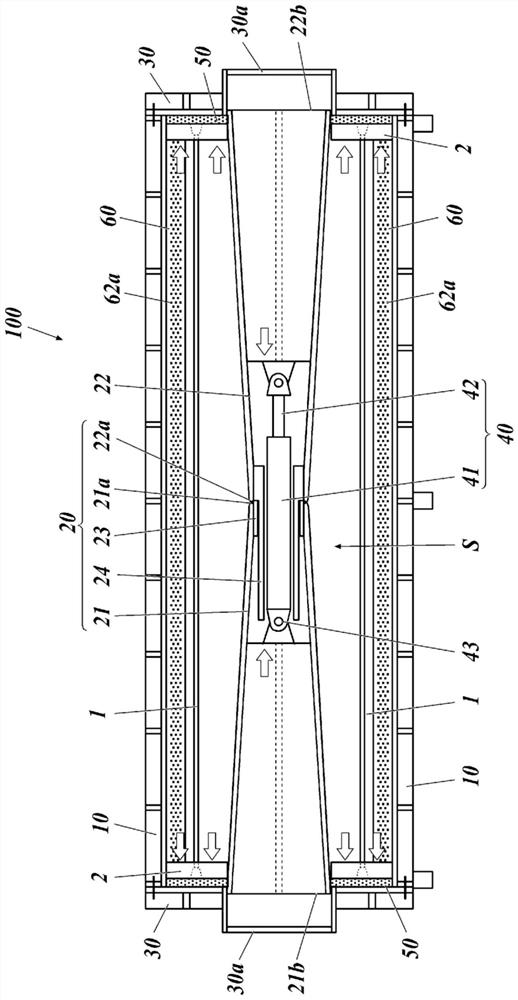

[0043] Such as Figure 1A , 1B As shown, the concrete pile manufacturing apparatus 100 of the present embodiment includes: an outer formwork main body 10 assembled into a substantially square tube shape, an inner formwork 20 disposed inside the outer formwork main body 10 , and a plug to close the outer formwork main body 10 . Open end frame 30 etc. at both ends.

[0044] The outer formwork main body 10 is assembled so as to house a steel rod 1 extending in a predetermined direction and a pair of joint metal fittings 2 fixed to both ends of the steel rod 1 inside.

[0045] The steel rod 1 is, for example, a prestressed concrete steel rod (PC steel rod), and is a core material for reinforcing steel bars o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap