Food detection equipment with sample screening and conveying function

A technology with food detection and transmission functions, which is applied in the field of food detection equipment with sample screening and transmission functions, can solve problems such as poor detection efficiency, achieve the effect of reducing particle size and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

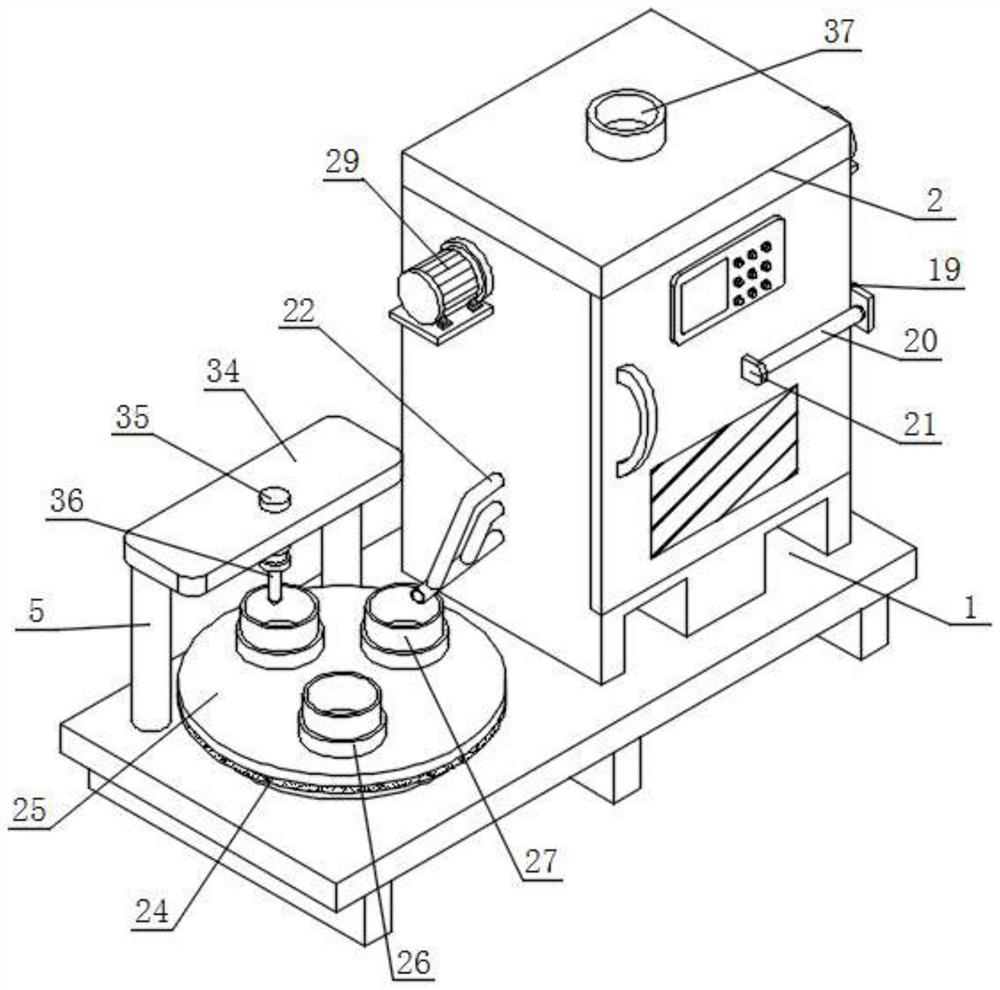

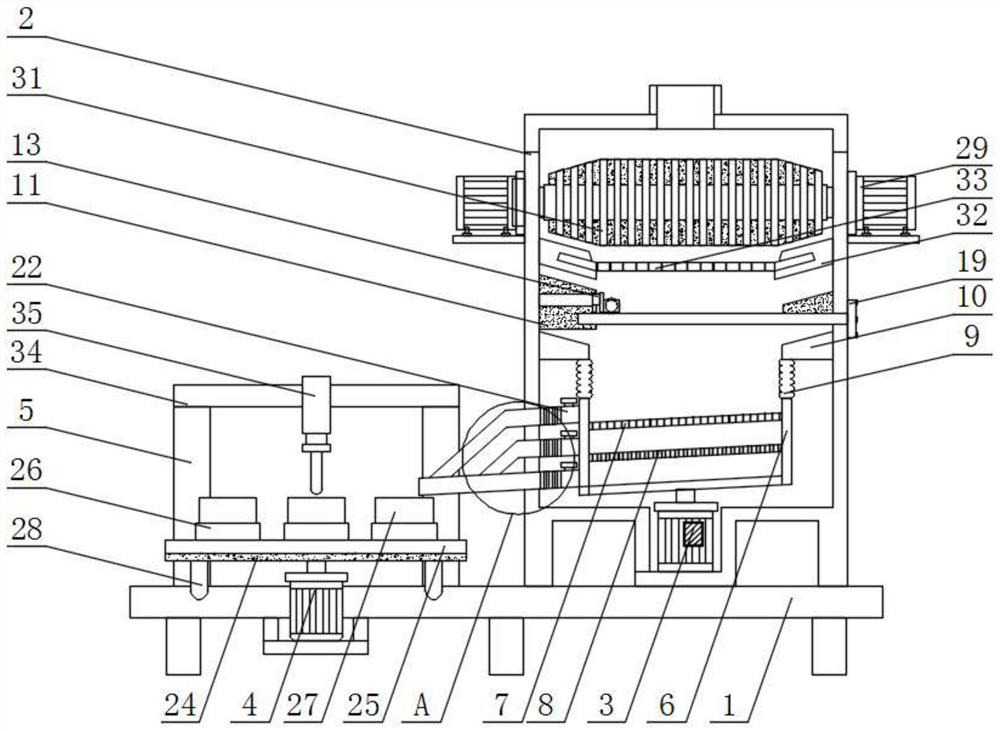

[0043] Such as figure 2 and image 3 As shown, a food testing device with the function of sample screening and transmission includes a bottom plate 1, a screening box 2, a vibration motor 3, a rotating motor 4 and a column 5, the top of the bottom plate 1 is equipped with a screening box 2, and the bottom of the bottom plate 1 is installed with a storage box;

[0044] Specifically, the bottom plate 1 is used to place the sieve component and the detection component in the same space, so that the sieved samples are conveniently transferred to the detection mechanism, and the screening box 2 is provided for crushing and sieving the sample food that needs to be tested. The relatively safe space makes its operation free from external interference, and the storage frame provides a relatively stable place for the rotating motor 4, and makes the distance between the workbench 24 installed on the top of the rotating motor 4 and the bottom plate 1 smaller, for Sufficient space is res...

Embodiment 2

[0050] Such as figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, the side inner wall of the screening box 2 close to the column 5 is equipped with an engaging block 11, the inner wall of the engaging block 11 is equipped with a planar plate 12, and one side of the outer wall of the planar plate 12 extends out of the inside of the screening box 2, snapping One side outer wall of block 11 is provided with two groups of notches that are arranged front and back, and the inner walls of two groups of notches are all equipped with multi-section electric push rods 13, and one end of multi-section electric push rods 13 extends out of the inside of the notch, two One end of a group of multi-section electric push rods 13 is equipped with connecting flaps 14, and the front of one group of connecting flaps 14 is equipped with a rotating rod 15, and the back side of the rotating rod 15 runs through the inside of another group of connecting flaps 14. The outer surface of the rod 1...

Embodiment 3

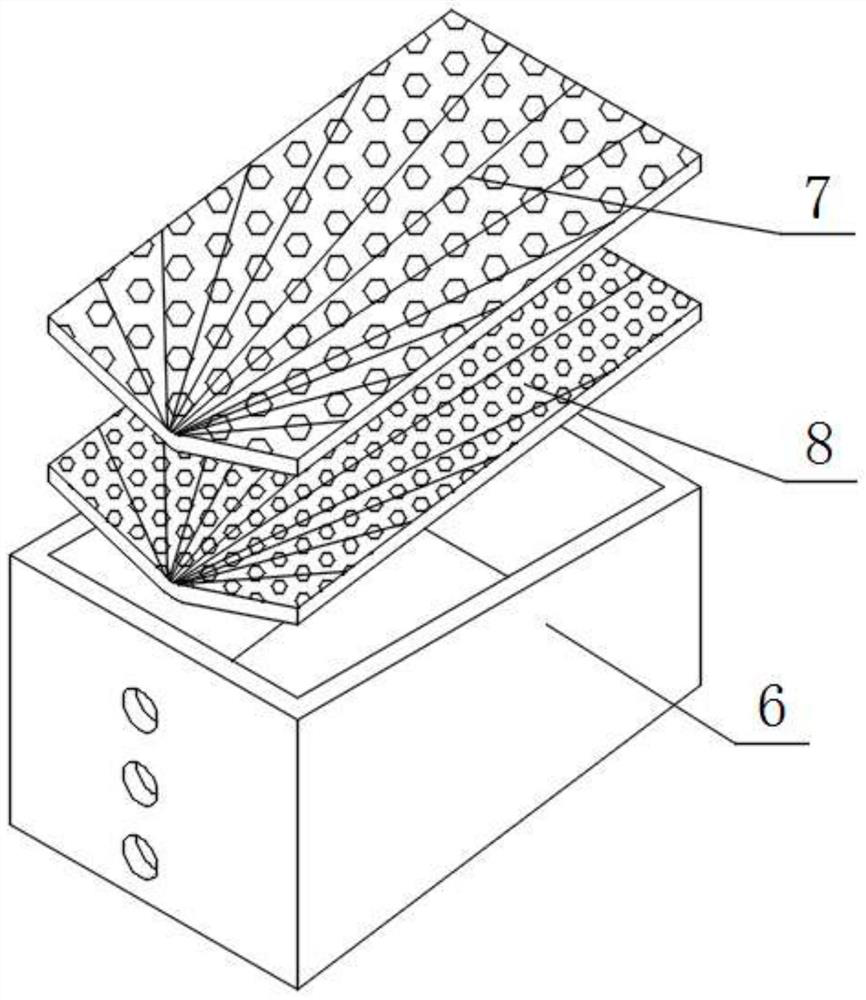

[0055] Such as figure 2 and Figure 8As shown, three groups of inclined tubes 22 arranged up and down are installed on one side of the collection box 6, and the tail ends of the two groups of inclined tubes 22 extend into the inside of another group of inclined tubes 22, and the tops of the three groups of inclined tubes 22 are An electronic valve 23 is installed.

[0056] Specifically, the three groups of inclined tubes 22 are respectively used to transmit the sample food on the top of the two-component sieve plate and the bottom wall of the collection frame, and the three groups of inclined tubes 22 are arranged up and down, and the tail ends of the two groups of pipes above it all extend into the Inside the lower inclined pipe 22, the opening and closing of the electronic valve 23 can be used to control the dredging and blocking of the inclined pipe 22. When the electronic valve 23 on the corresponding pipe is opened, the sieve plate or collection frame 6 corresponding to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap