Plasma bag residual liquid recovery device and plasma bag residual liquid recovery method

A recovery device and plasma bag technology, which is applied in the field of plasma collection, can solve the problems of raw material plasma waste and achieve the effects of ensuring recycling, smooth placement process, and convenient cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

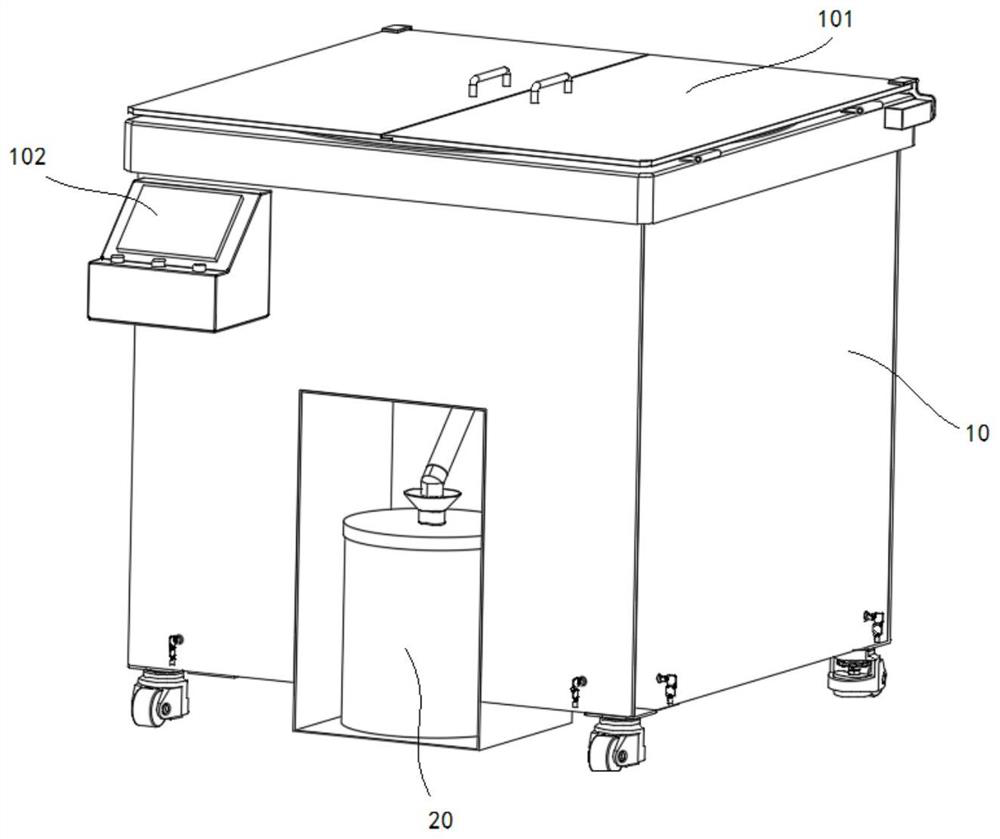

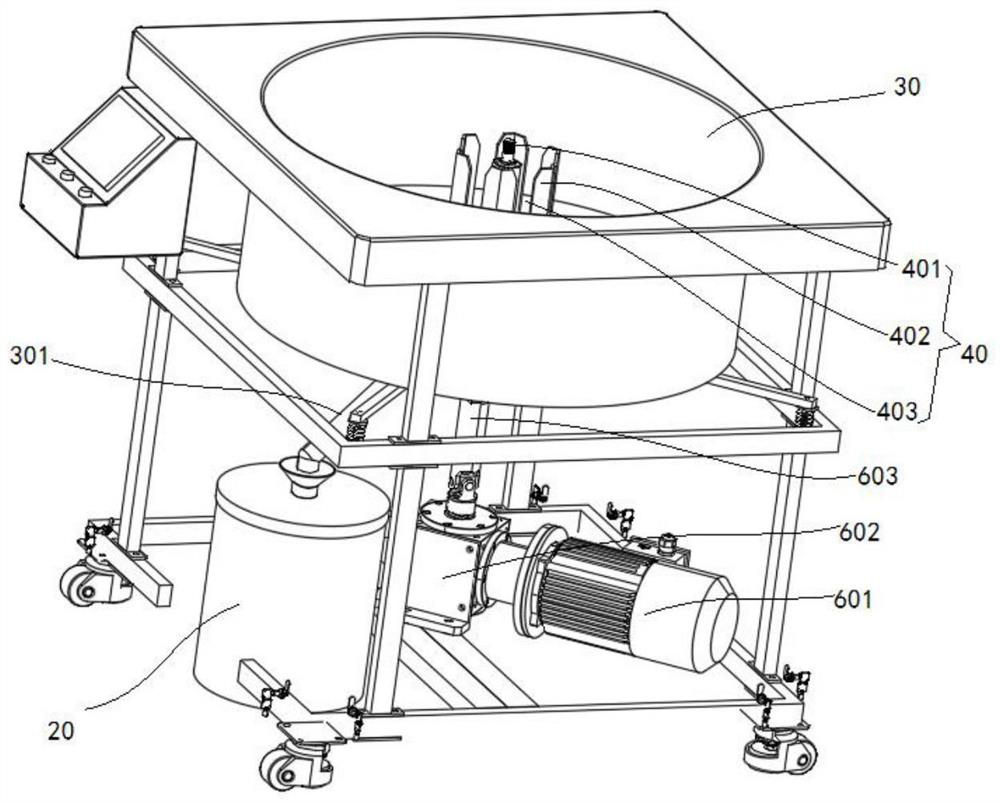

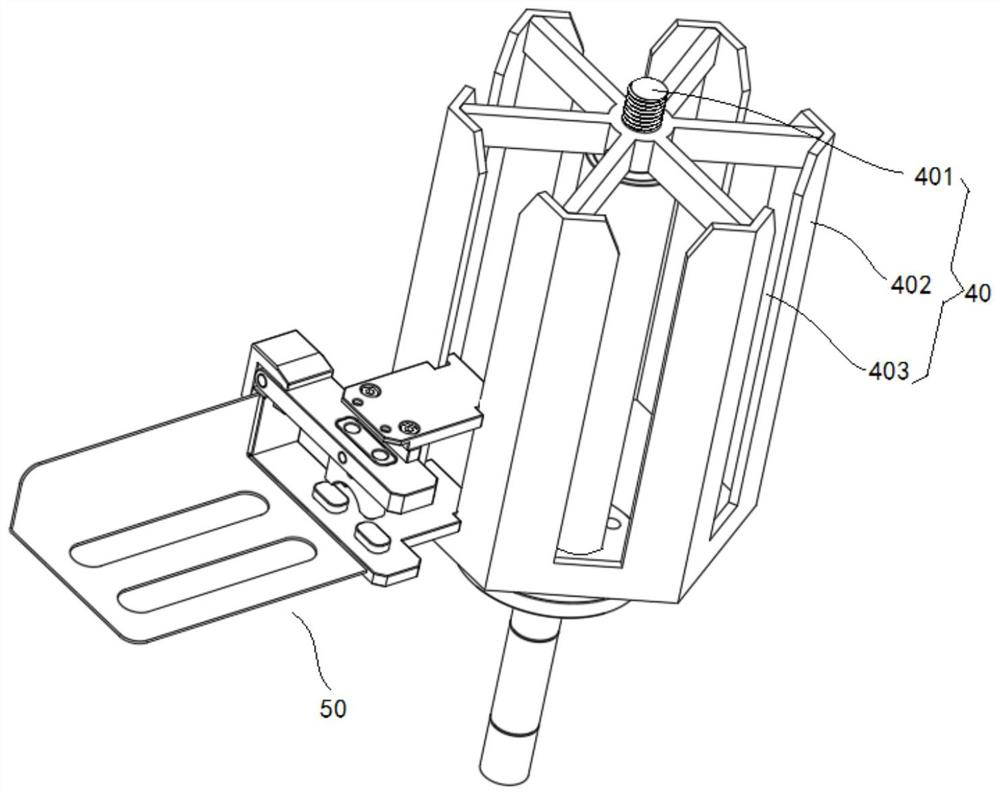

[0042] Such as Figure 1 to Figure 10 As shown, a plasma bag residual fluid recovery device includes a frame body 10, a collection bucket 20, a buffer liner 30, a centrifugal cage 40, a holder 50 and a drive mechanism 60, and the inside of the frame body 10 is installed There is a buffer liner 30, and the bottom is provided with a collection barrel 20 communicating with the inside of the buffer liner 30 (the buffer liner 30 communicates with the collection barrel 20 through a draft tube 301), and the centrifugal cage 40 passes through The rotating shaft 401 is installed in the interior of the buffer liner 30 for circumferential rotation, the centrifugal cage 40 is evenly arranged along the circumferential direction, and is detachably connected with a plurality of holders 50, and the driving mechanism 60 is located in the buffer liner. Below the inner tank 30 , the driving mechanism 60 is connected to the part of the rotating shaft 401 extending out of the bottom of the buffer ...

Embodiment 2

[0052] In order to solve the technical problems in the above-mentioned embodiment 1, a method for recovering plasma bag residual liquid is provided, which includes the following steps: vertically stack the plasma bags to be processed, and place them on the fixing clamp, the placing plate and the lower connection on the placement plane formed by the block; turn over the movable clamp block so that the plasma bag to be treated is located in the clamping space between the movable clamp block and the fixed clamp block, and fix the clamp; clamp all the plasma bags to be processed The gripper is snapped into a slot corresponding to the centrifugal cage; the drive motor is driven to rotate the centrifugal cage through the drive shaft to generate centrifugal force, so that the plasma in the plasma bag to be processed is thrown into the buffer liner and passed through The guide tube guides the plasma obtained in the buffer liner into the collection bucket for collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com