Positioning and cutting device for plastic product processing

A technology for positioning cutting and plastic products, applied in the field of plastic processing, can solve the problems of cumbersome and complicated work process, unable to quickly achieve positioning and cutting of plates, etc., and achieve the effect of increasing the collection range and accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

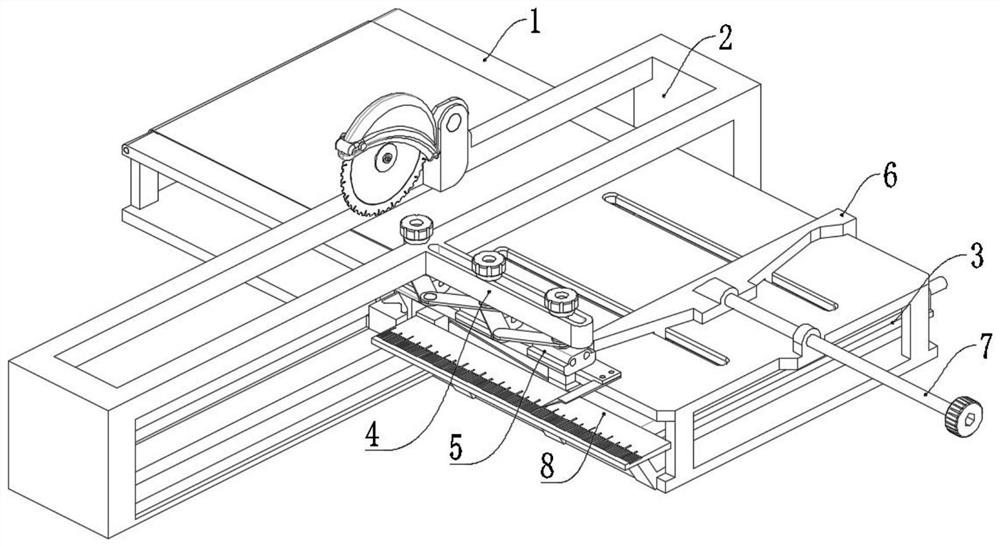

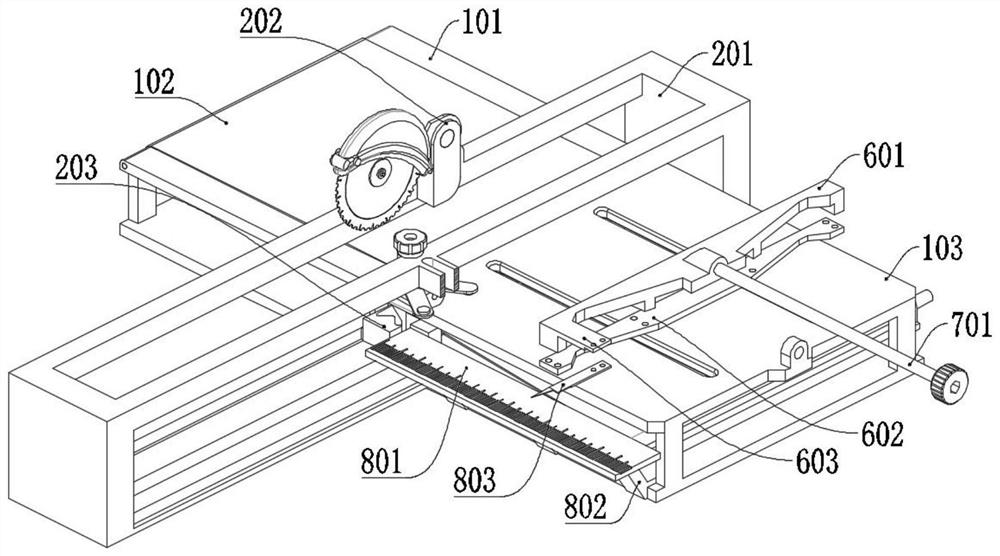

[0058] Example 1: Please refer to Figures 1 to 10 :

[0059] The present invention proposes a positioning cutting device for processing of plastic product, including: carrier structure 1;

[0060] Carrying structure 1, the bearing structure 1 is slid in the intermediate position of the vehicle, and the cutting device 2 is mounted, and the cutting device 2 is set to the left and right sliding direction.

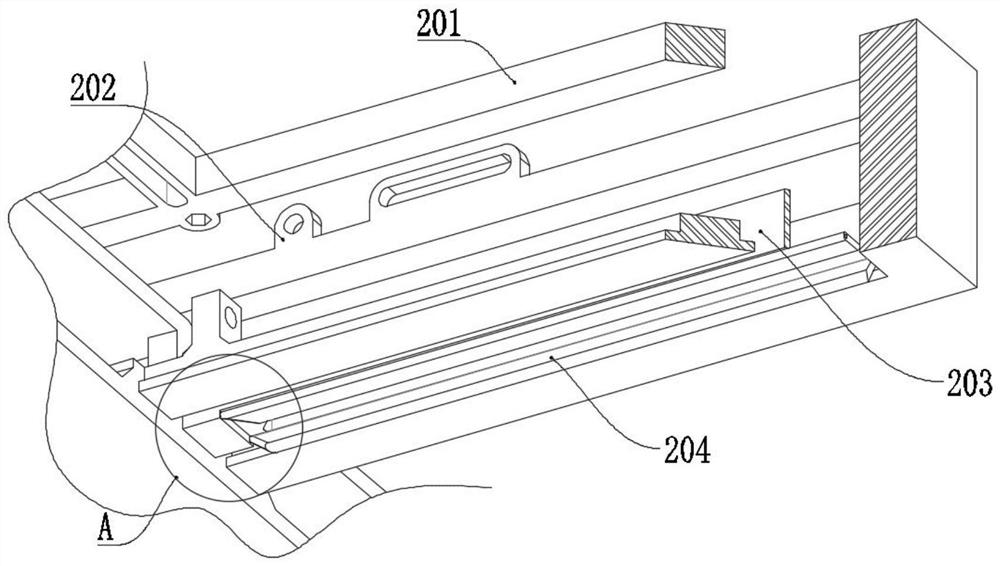

[0061] Further, according to an embodiment of the present invention, such as Figure 1-2 As shown, the carrier structure 1 includes:

[0062] The feed plate 101, the feed plate 101 is a structure of the upper and lower bilateral, and the front and rear end position of the feed plate 101 is mounted, and a transmission belt 102 is provided between the rolling shaft of the feed plate 101, by putting the feed plate 101 on the feed plate 101. Setting the transmission belt 102, which is advantageous to make the plastic plate more efficiently delivered in place;

[0063] The carrier plate...

Embodiment 2

[0071] Including: Upset Structure 3, the lower material structure 3 is disposed at the right side position of the front end of the cutting device 2, and the intermediate position of the top front end of the cutting device 2 is provided with the mounting device 4, and the bottom portion of the mounting device 4 is provided with auxiliary component 5.

[0072] Further, according to an embodiment of the present invention, such as Figure 7 As shown, the following structure 3 includes:

[0073] The extension 301, the extension 301 is fixed to the front end of the bottom of the slide frame 201, and two sets of rollers are provided on the extending frame 301, by fixing the extending frame 301 in the front end position of the bottom of the slider 201, facilitating the expansion of the installation Component;

[0074] The lower tape 302, the lower tape 302 is wound on the outer wall of the two sets of roller, and the roller and the extending frame 301 are arranged to be inclined, and the p...

Embodiment 3

[0085] Including: limit device 6, the limit device 6 provides a front end position of the carrier structure 1, and the limit device 6 is connected by the adjustment structure 7, and the front end of the carrier structure 1 is provided with a measurement component 8; adjustment structure 7 Including: adjustment lever 701, the adjustment lever 701 is rotated mounted in the intermediate position of the limit plate 601, and the adjustment lever 701 is simultaneously screwed on the projection mounted on the carrier plate 103, by rotating the adjustment lever 701 on the limit panel 601 It is advantageous to make the adjustment lever 701 can be rotated on the restricted plate 601, while the adjustment lever 701 is screwed on the projection head of the carrier plate 103, and the rotation adjustment rod 701 reaches the positional panel 601 position adjustment effect, The adjustment lever 701 is provided with a knob, and a groove having an inner wall is a hexagonal structure is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com