Foam cement insulation board film covering leveling device

A technology of foamed cement and insulation boards, applied in the direction of supply devices, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of controlling the thickness of mortar, not being able to expose the net, and the quality of fiber-reinforced foamed cement insulation boards cannot be guaranteed, and achieve Uniform thickness, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

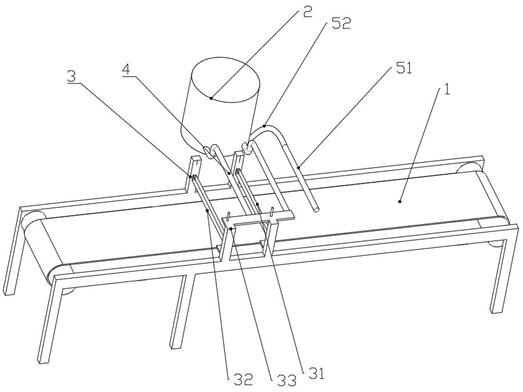

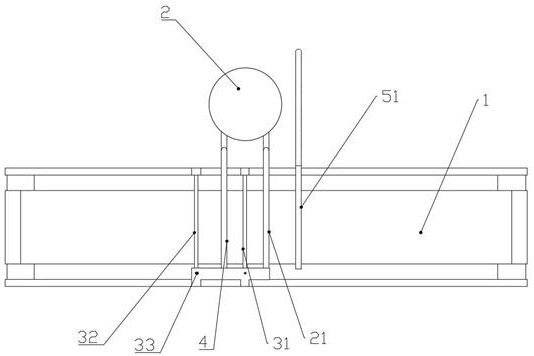

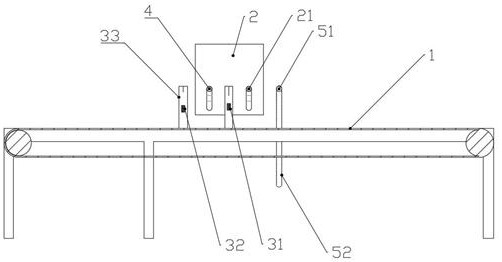

[0020] see Figure 1~3 , the present invention provides a foamed cement insulation board coating leveling device, comprising a batching storage tank, a batching conveying motor, a stirring tank 2, a conveyor belt 1, and a scraping device 3, and the feed port of the batching conveying motor passes through a pipeline and a batching The storage tank is connected, and the discharge port of the batching conveying motor is connected with the stirring tank 2 through a pipeline. The bottom of the stirring tank 2 is provided with a discharge pipe 21, and the outlet of the discharge pipe 21 is located directly above the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com