Injection molding direct-drive glue injection structure

A technology of direct drive and glue injection, which is applied in the field of injection molding direct drive glue injection structure, can solve the problems of complex installation process of synchronous wheel, large rotation noise of synchronous belt, poor matching of injection mechanism, etc., achieve compact structure, reduce power transmission link, The effect of ensuring the accuracy of the bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

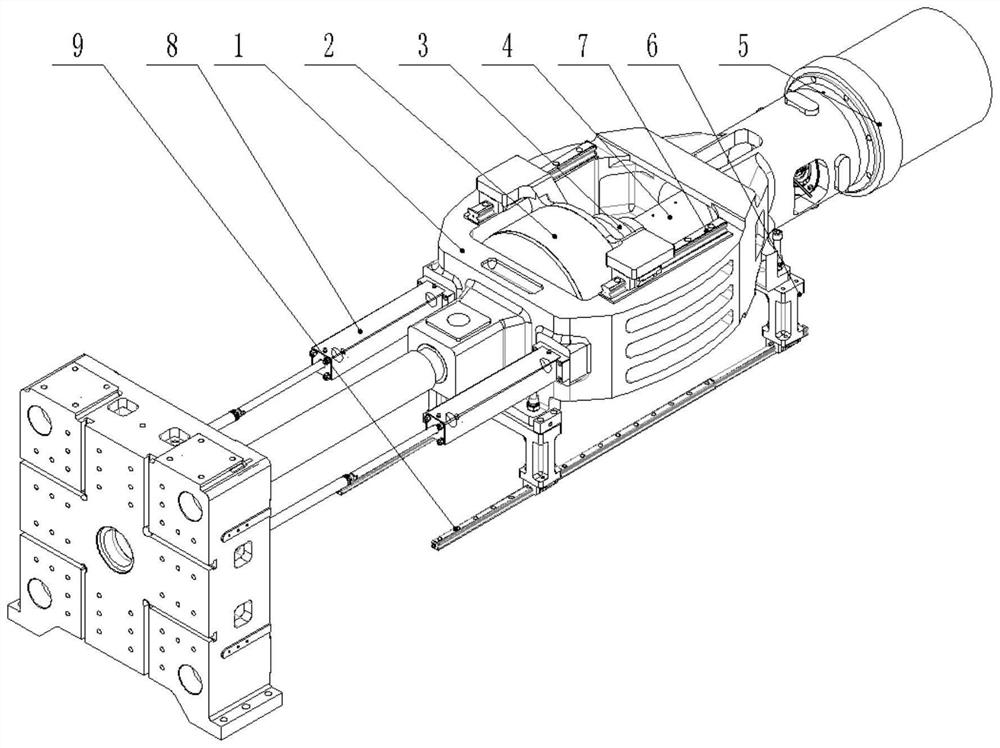

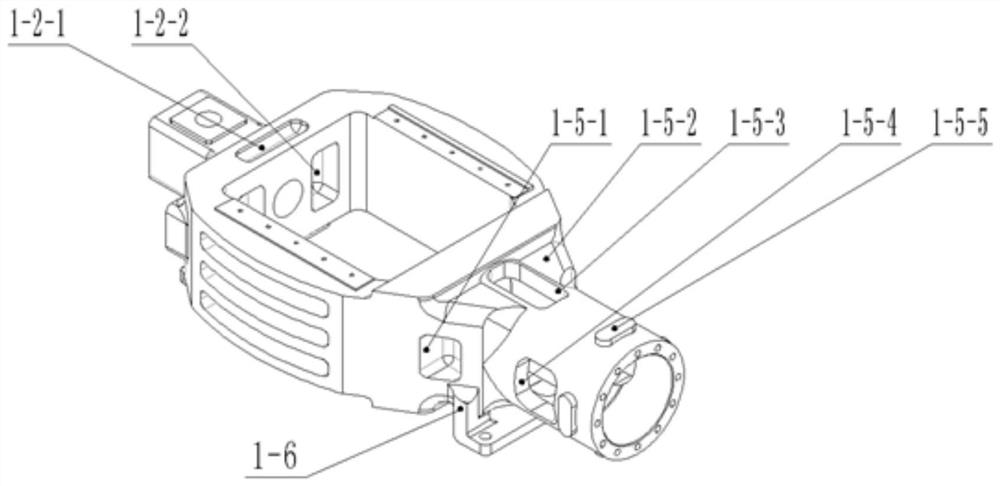

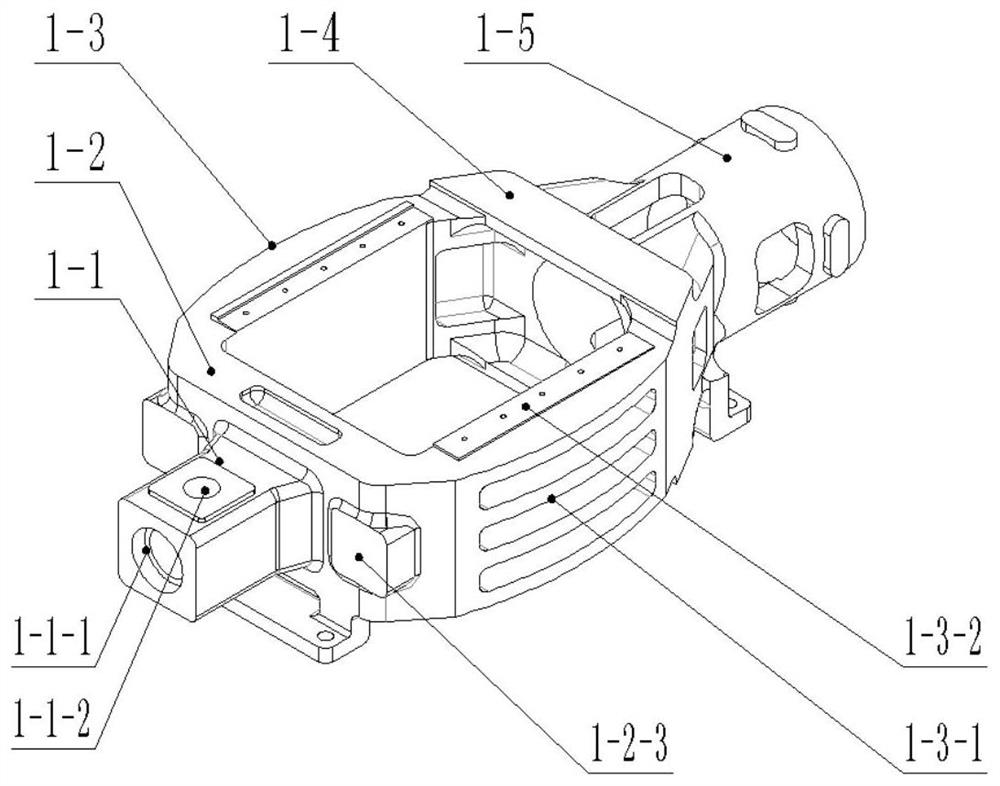

[0024] see Figure 1-Figure 4 As shown, an injection molding direct-drive injection structure includes an injection platform main body 1 and an injection linear guide rail 9. The four corners of the bottom of the injection platform main body 1 are fixedly provided with an injection support 6, and the injection platform main body 1 is provided with two parallel guide rails. One and located at the bottom of the shooting platform main body 1, the shooting platform main body 1 is set by sliding between the shooting platform bracket 6 and the shooting linear guide rail 9, the shooting platform main body 1 is fixedly provided with shooting oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com