High-bearing-capacity semi-submersible type drilling platform sea wave compensation device and control method

A technology of drilling platform and compensation device, which is applied in the direction of transportation and packaging, equipment for increasing the stability of ships, ships, etc., can solve the problems that the deck level of the drilling platform cannot be achieved, and achieve high motion control precision, good stability, and accurate compensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

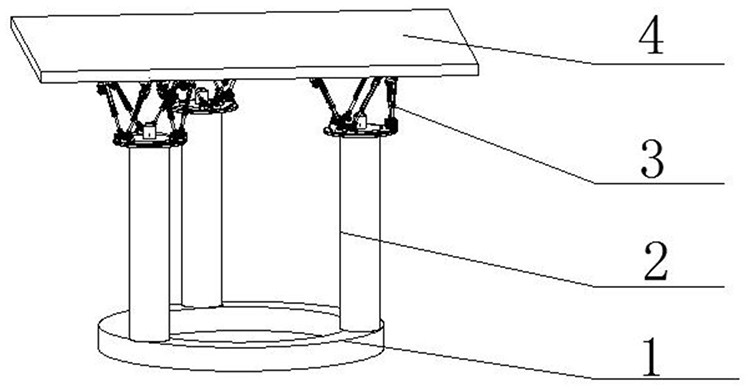

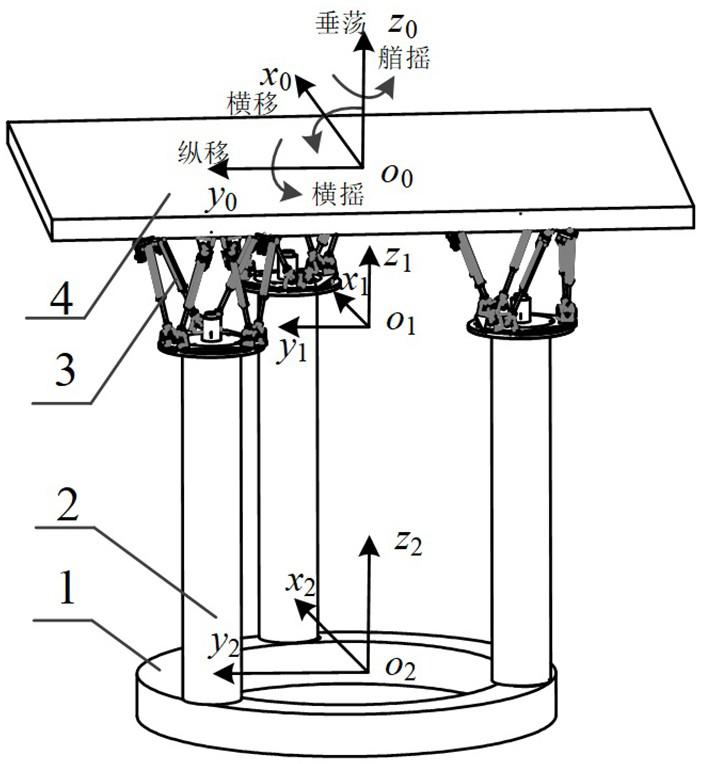

[0048] Embodiment one, such as figure 1 , 2 As shown, a high-load semi-submersible drilling platform sea wave compensation device includes a buoyancy tank 1, a load-bearing pillar 2, a parallel attitude adjustment module 3, a wave recognition module, a data processing module 13, a control and drive module 14, and a drilling platform deck 4.

[0049] The buoyancy tanks 1 are ring-shaped, arranged under the semi-submersible drilling platform and suspended below the sea surface. The function of the buoyancy tanks 1 is to keep the drilling platform floating on the sea surface by buoyancy.

[0050] The load-bearing pillar 2 is cylindrical, and the load-bearing pillar 2 is located above the annular buoyancy tank. The axis of the load-bearing pillar 2 is located on the circumference of a specific circumscribed circle.

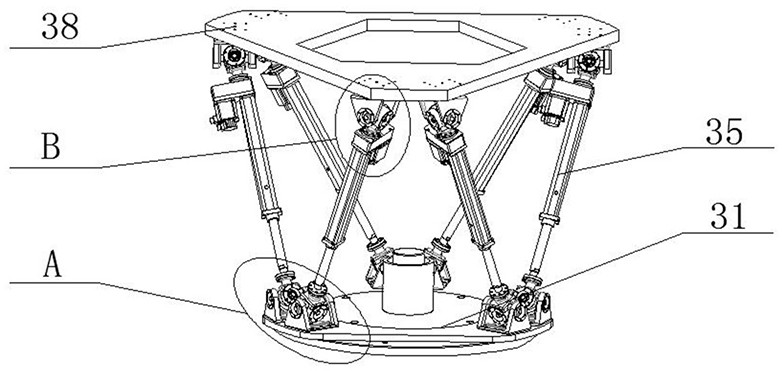

[0051] Such as image 3 , 4 As shown in and 5, the parallel attitude adjustment module 3 is located between the supporting pillar 2 and the drilling platform deck...

Embodiment 2

[0068] Embodiment two, such as Figure 11 As another embodiment of the present invention, the number of bearing pillars 2 and parallel attitude adjustment modules 3 is 6, and the sea wave compensation device and its control method for a high-load semi-submersible drilling platform provided by this embodiment are similar to those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com