Polyurethane/epoxy sliding ring damping coating and preparation method thereof

A damping coating and polyurethane technology, applied in the field of damping materials, can solve the problems of high permanent deformation rate of coatings, stress concentration, poor mechanical properties of coatings, etc., and achieve the effect of reducing fracture and reducing permanent deformation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

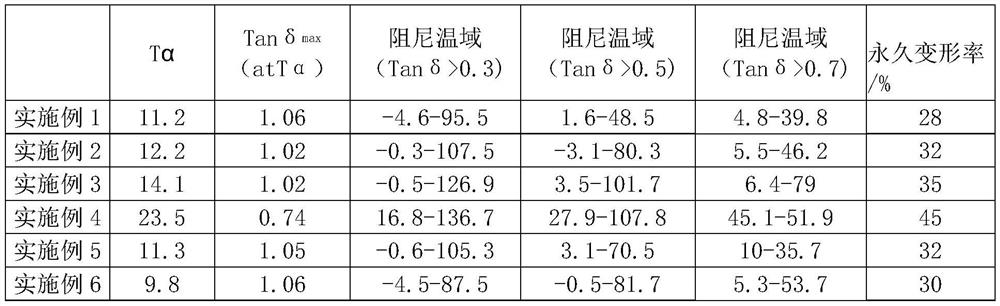

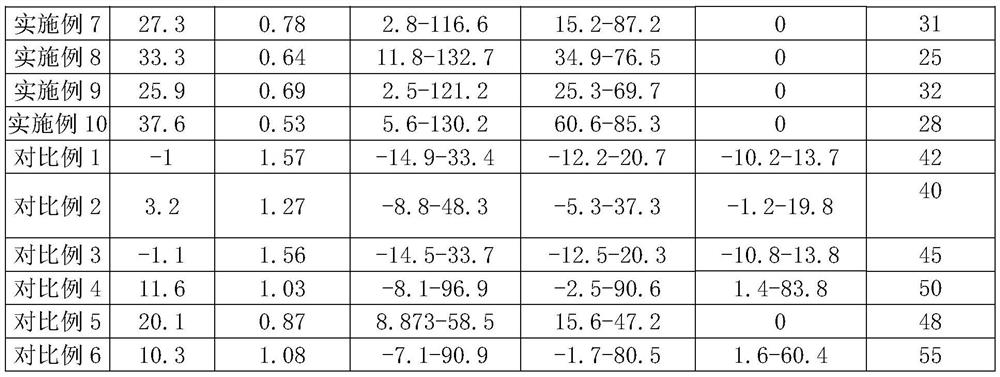

[0045] Experimental example: Damping coating obtained by the above-described Examples 1-10 and Comparative Examples 1-6, using DMA equipment to measure the damping value of the coating at each temperature, as shown in Table 3.

[0046] Table 3 is the damping performance of Examples 1-10 and the contrast 1-6 coating

[0047]

[0048]

[0049] In the above Table 3, the units of each data are ° C, wherein the Tα represents the temperature corresponding to the maximum damping value, and TANΔmax (attα) represents the maximum damping value of the coating.

[0050] From the above Table 3, the coating of Examples 1-10 can be obtained, with excellent damping properties and mechanical properties, and the temperature range of the coating tan δ> 0.3 of Example 1-4 is 99.1 ° C, 107.8 ° C, 127.4 ° C, respectively. 119.9 ° C. The permanent deformation rate of the coating can be as low as 28%. In Comparative Example 1-6, the temperature range of the coating tan δ> 0.3 is 48.3 ° C, 57.1 ° C, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com