Hook piece and manufacturing method thereof

A U-shaped, lug-plate technology, applied to building components, cladding/lining, walls, etc., can solve problems such as poor fit of main beams, unstable components, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Please refer to Figure 1-Figure 5 , is shown as an embodiment of the invention.

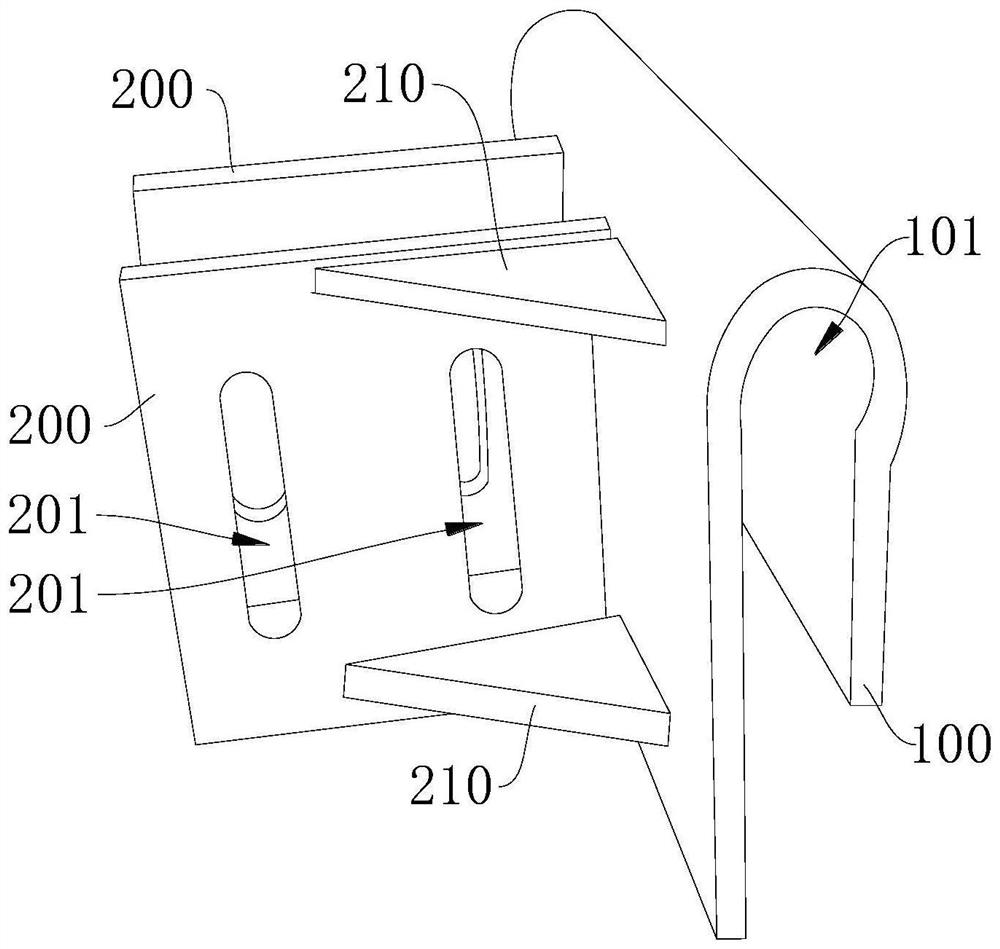

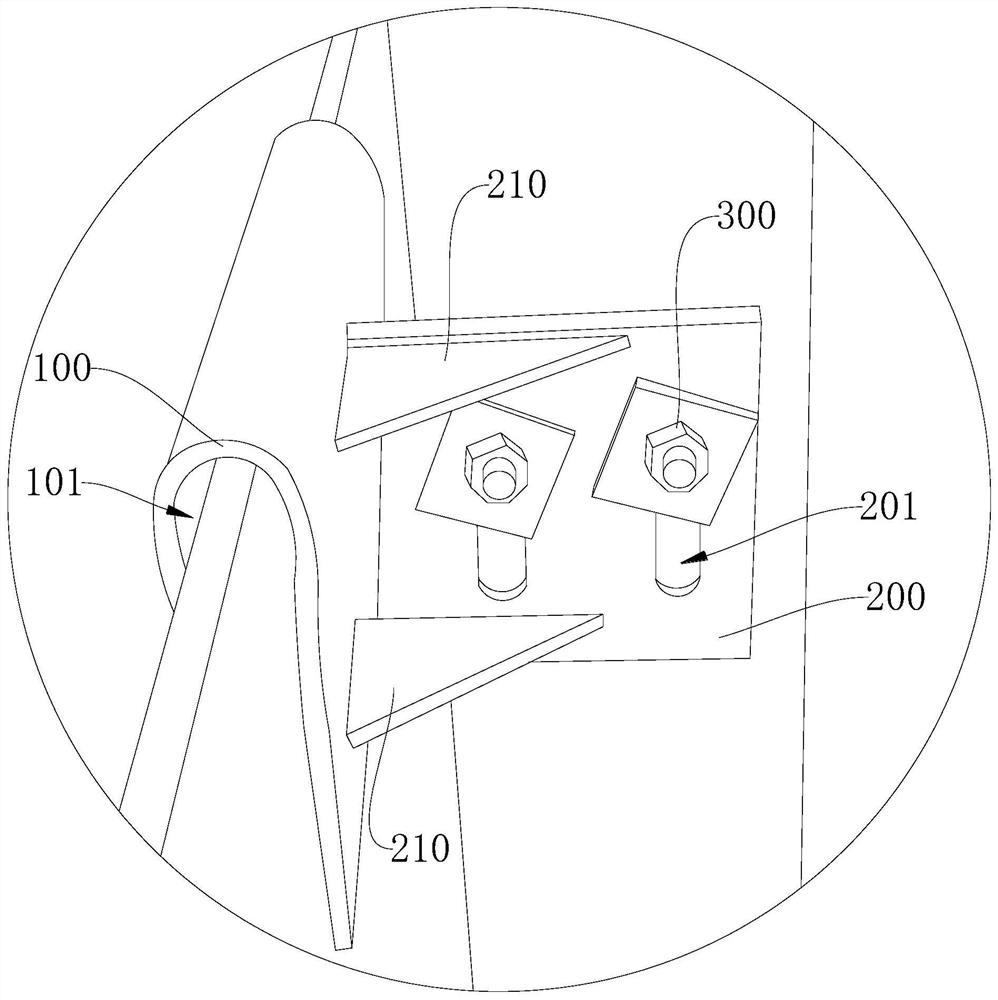

[0049] like figure 1 , 2 As shown, the embodiment of the present application provides a hook piece, which includes a U-shaped piece 100 connected to each other and two lugs 200 , the U-shaped piece 100 has a slot 101 , and the two lugs 200 are arranged alternately.

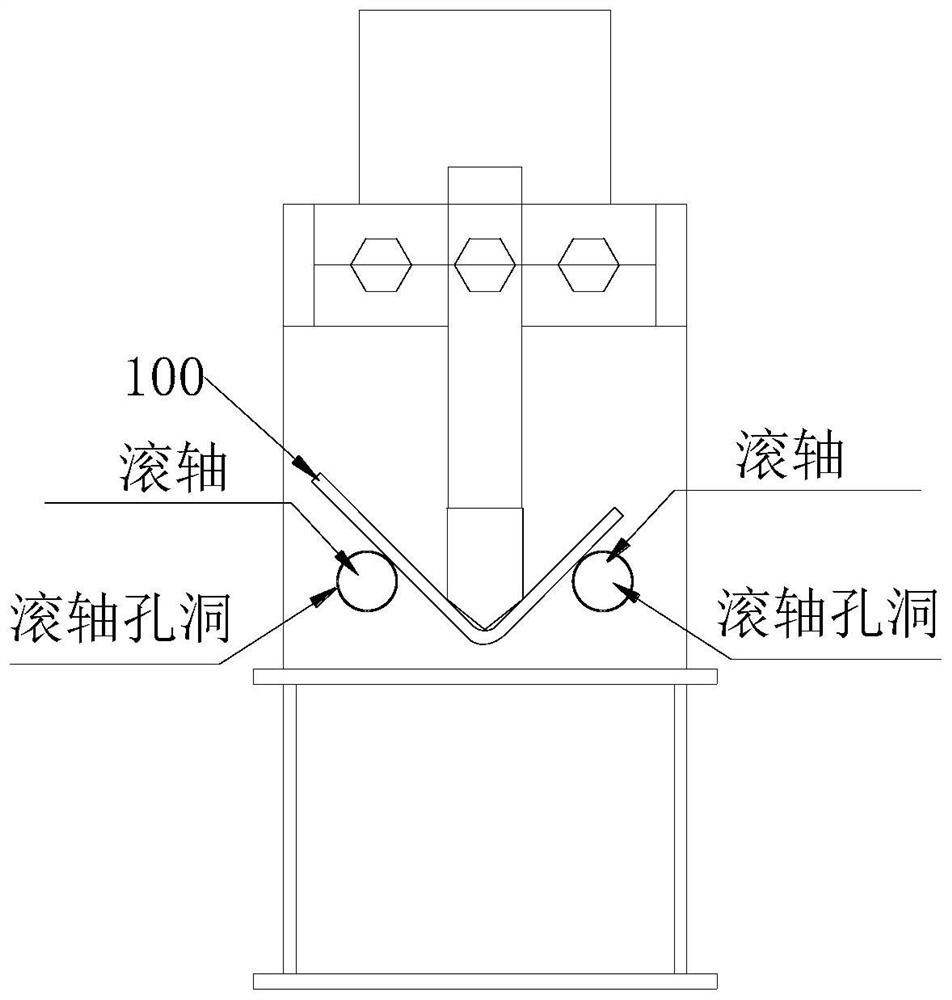

[0050] In this embodiment, the U-shaped piece 100 is fixedly connected to the two ear plates 200 . The U-shaped piece 100 is used for inserting the main beam skewer therein. At this time, the bending part of the U-shaped piece 100 is located on the upper side of the main beam, and the two sides of the U-shaped piece 100 are respectively located on both sides of the main beam. The ear plates 200 are used to be fixed on the main column of the keel, and the two ear plates 200 are respectively located on both sides of the main column of the keel.

[0051] In this embodiment, the embedding groove 101 of the U-shaped member 100 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com