Full-automatic platform gauge measuring method based on laser radar

A technology of laser radar and measurement method, which is applied to measurement devices, radio wave measurement systems, and re-radiation of electromagnetic waves, etc., can solve problems such as unfavorable unification, automated surveys, ordinary cameras have no depth information, and measurement time is limited, etc. Achieve the effect of improving the overall measurement accuracy, wide scanning coverage, and improving segmentation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

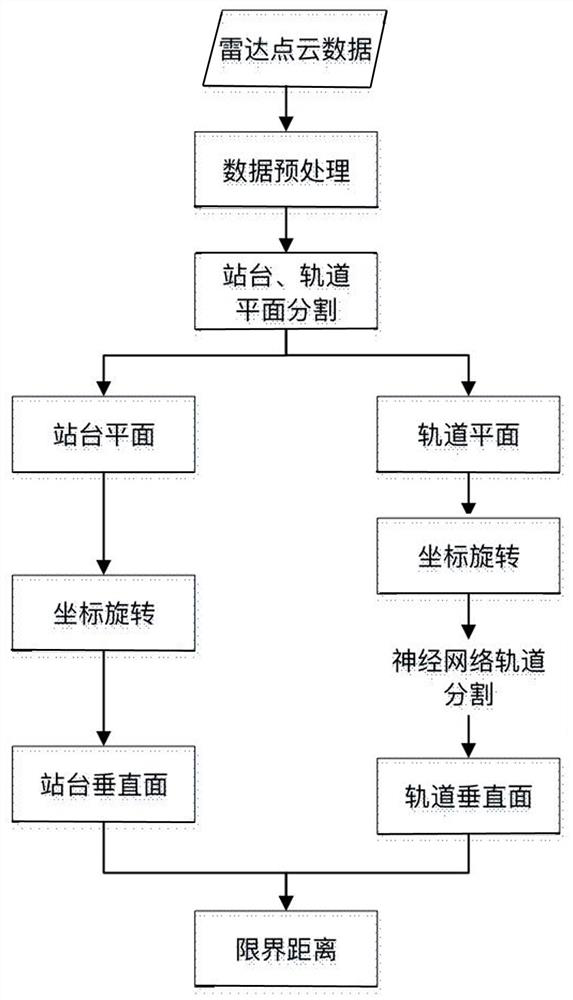

[0060] This embodiment is a fully automatic platform boundary measurement method based on laser radar, which specifically includes the following steps:

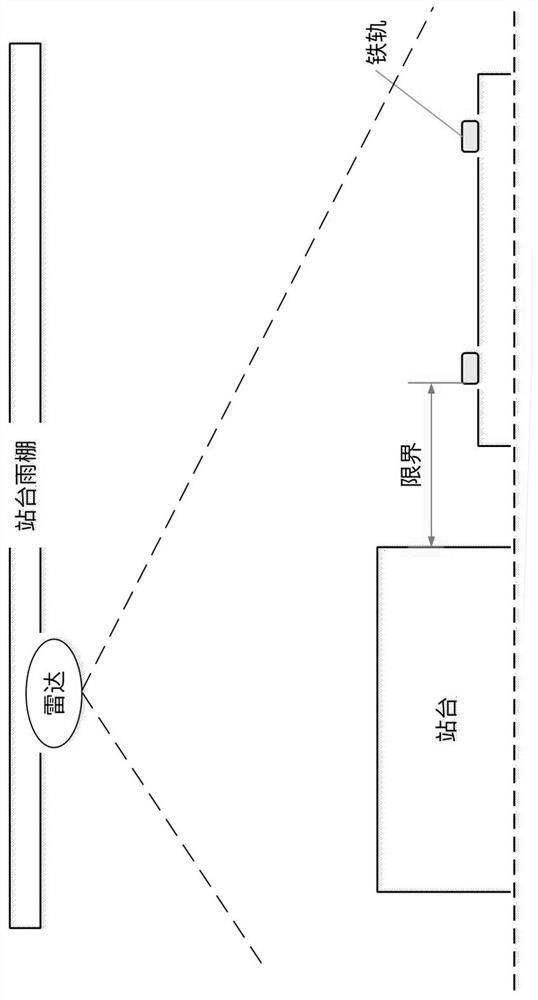

[0061] S1. Obtain the point cloud data of the station and track area; scan the station and track area with laser through the laser radar installed on the top of the platform, obtain point cloud data through calculation, and filter the 3D point cloud data to remove noise .

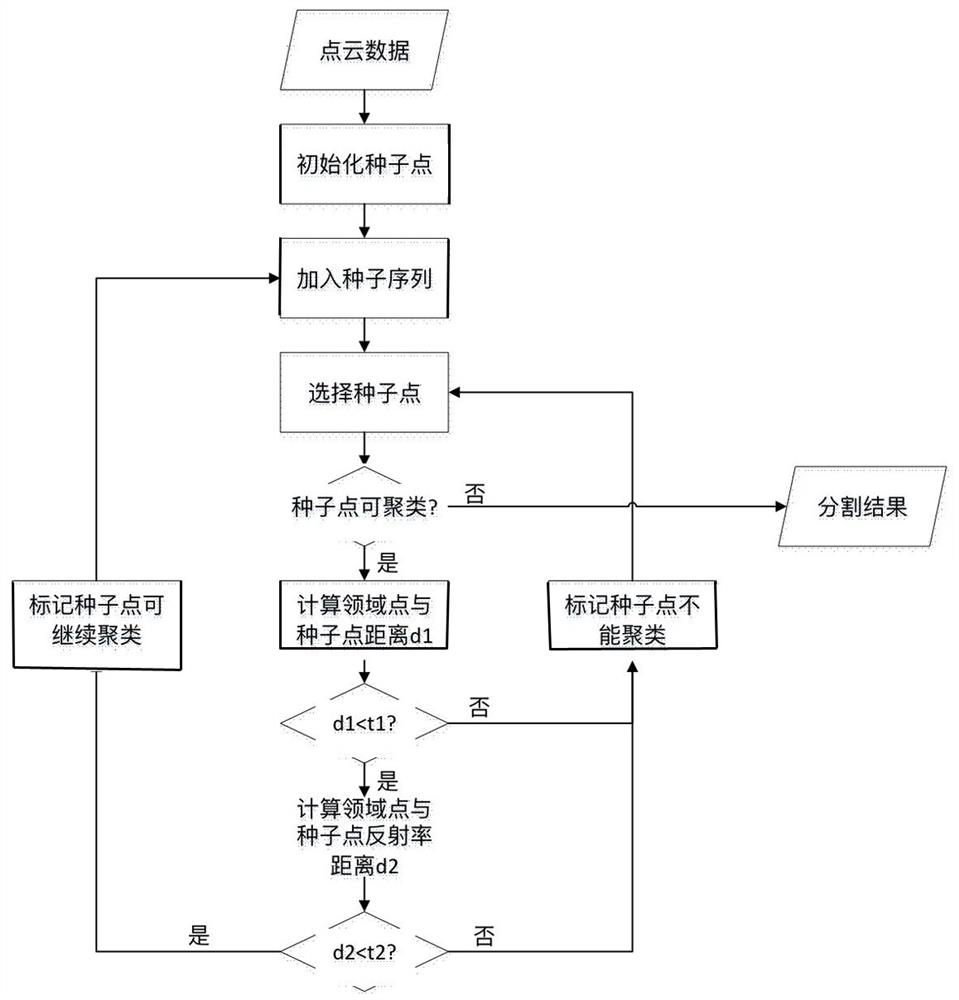

[0062] S2. Using a traditional segmentation algorithm based on region growing, segment the platform plane and the track plane. Since the reflectivity of the platform and the track plane are different, the reflectivity information is added to the region growing segmentation, and the specific steps are as follows:

[0063] (1) Obtain point cloud data, initialize seed points, and add them to the seed sequence

[0064] (2) Select the seed points marked as clusterable, and if the seed points are marked as non-clusterable, exit the process and obtain the segme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap