Liquid crystal conical lens, driving method thereof and imaging device based on liquid crystal conical lens

A technology of conical lens and liquid crystal, applied in the field of conical lens, can solve the problems of complex structure of liquid crystal conical lens, and achieve the effect of simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

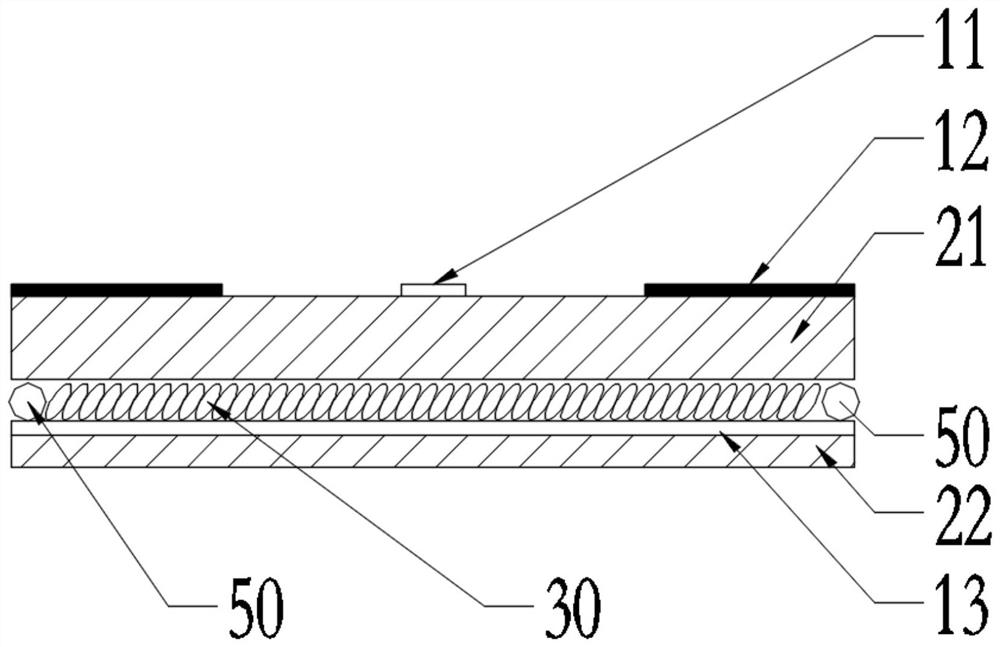

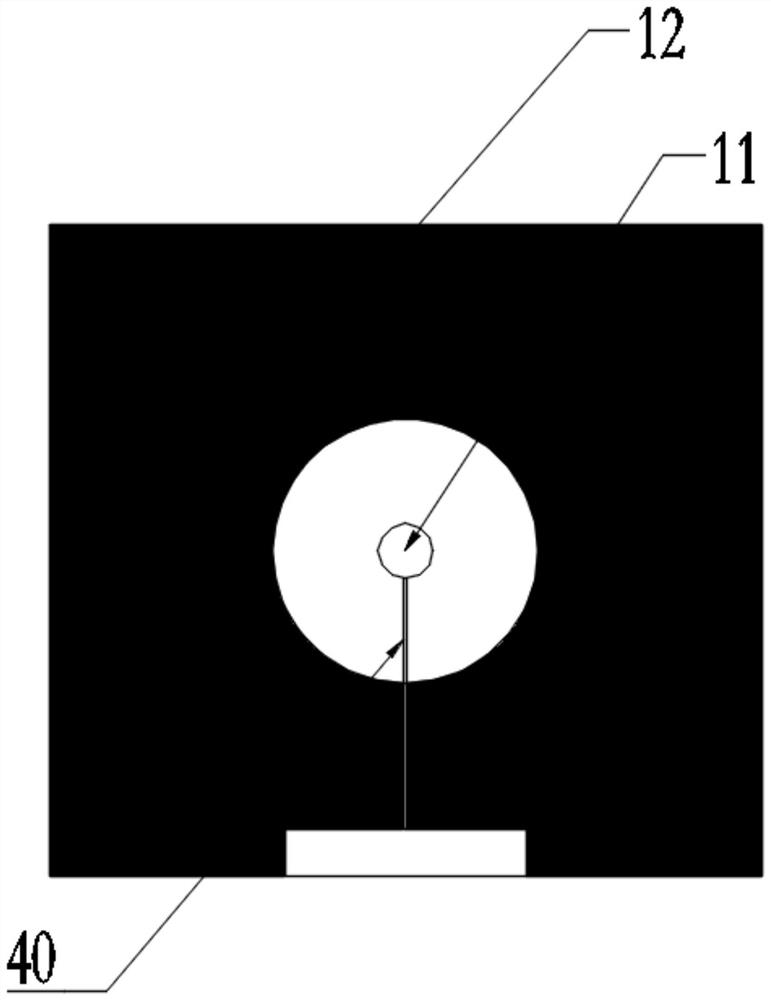

[0038] Such as figure 1 As shown, the present embodiment provides a liquid crystal axicon, which includes a circular transparent electrode 11, a circular hole electrode 12, a first transparent substrate 21, a liquid crystal layer 30, a first transparent electrode 13 and a second transparent electrode 12 arranged in sequence. Transparent substrate 22, the circular transparent electrode 11 and the circular hole electrode 12 are located on the side of the first transparent substrate 21 facing away from the liquid crystal layer 30, the center of the circular transparent electrode 11 and the circular hole electrode 12 The projections of the centers of the circular holes on the same reference plane coincide, and the reference plane is a plane perpendicular to the central axis of the circular hole electrode 12 .

[0039]The circular transparent electrode 11 can be in the shape of a small disc, and the electrode can be a circular ITO electrode, IZO electrode, FTO electrode, AZO electr...

Embodiment 2

[0047] Such as image 3 As shown, the present embodiment provides another liquid crystal axicon, which includes a circular transparent electrode 11, a circular hole electrode 12, and a first transparent substrate 21, a liquid crystal layer 30, and a first transparent electrode arranged in sequence. 13 and a second transparent substrate 22, the circular transparent electrode 11 and the circular hole electrode 12 are located on the side of the first transparent substrate 21 facing away from the liquid crystal layer 30, the center of the circular transparent electrode 11 and The projections of the center of the circular hole of the circular hole electrode 12 on the same reference plane coincide, and the reference plane is a plane perpendicular to the central axis of the circular hole of the circular hole electrode 12 . The liquid crystal axicon also includes a third transparent substrate 23, the third transparent substrate 23 is located on the side of the hole electrode 12 facing...

Embodiment 3

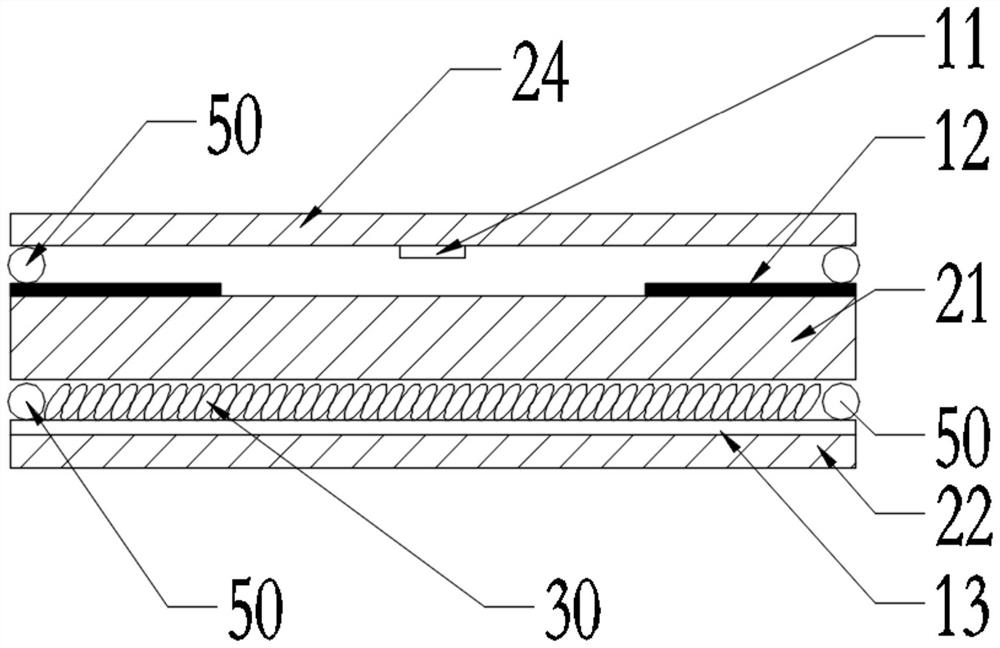

[0057] Such as Figure 5 As shown, the present embodiment provides another liquid crystal axicon, which includes a circular transparent electrode 11, a circular hole electrode 12, and a first transparent substrate 21, a liquid crystal layer 30, and a first transparent electrode arranged in sequence. 13 and a second transparent substrate 22, the circular transparent electrode 11 and the circular hole electrode 12 are located on the side of the first transparent substrate 21 facing away from the liquid crystal layer 30, the center of the circular transparent electrode 11 and The projections of the center of the circular hole of the circular hole electrode 12 on the same reference plane coincide, and the reference plane is a plane perpendicular to the central axis of the circular hole of the circular hole electrode 12 . In order to apply the second driving voltage to the circular electrodes, in this embodiment, the liquid crystal axicon further includes an electrode lead-out line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com