Contaminated object microwave disinfection conveying cabin for biosafety

A biosafety and microwave disinfection technology, applied in the field of sewage treatment, can solve the problems of insignificant effect, environmental and personnel pollution, pathogen leakage, etc., and achieve the effects of convenient operation, reduced pollution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

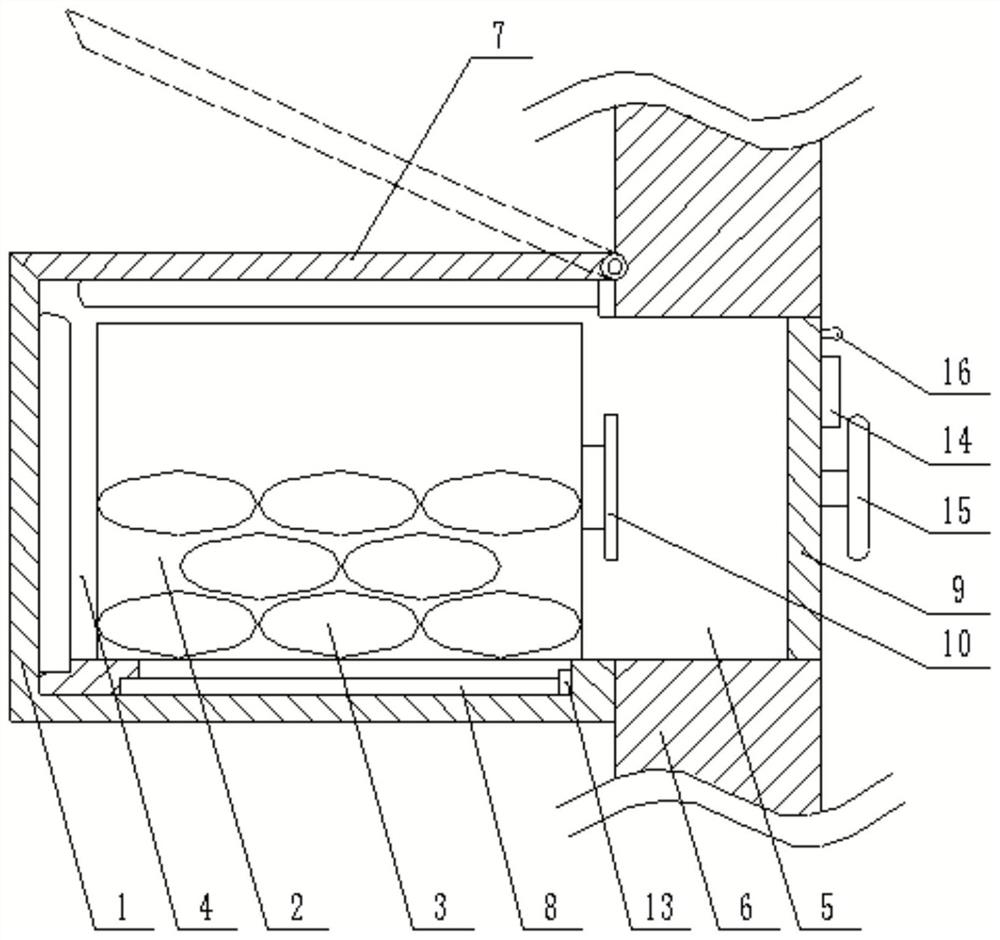

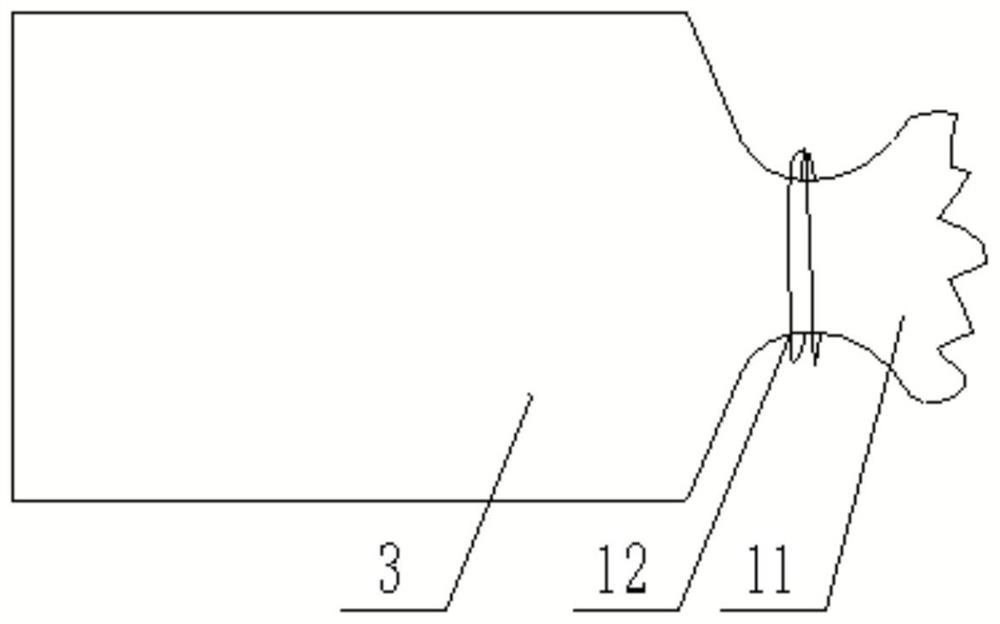

[0030] refer to Figure 1-2 , the present embodiment provides a microwave disinfection transmission cabin for biological safety, including a transmission cabin main body 1, a storage basket 2 is slidingly arranged inside the transmission cabin main body 1, and a plurality of dirt sealing bags 3 are contained in the storage basket 2; The dirt sealing bag 3 collects the dirt produced in the polluted area, and then puts it uniformly in the storage basket 2 and waits for disinfection treatment.

[0031] The main body 1 of the transfer cabin includes a storage chamber 4 and a sliding chamber 5 that communicate with each other. The storage basket 2 is located in the storage chamber 4, and the storage chamber 4 is located in the polluted area. The cavity 5 runs through the wall body 6 and is located in the wall body 6. The top cover 7 that can be lifted is installed on the top of the storage cavity 4, and a disinfection component is fixedly arranged in the storage cavity 4; Steriliz...

Embodiment 2

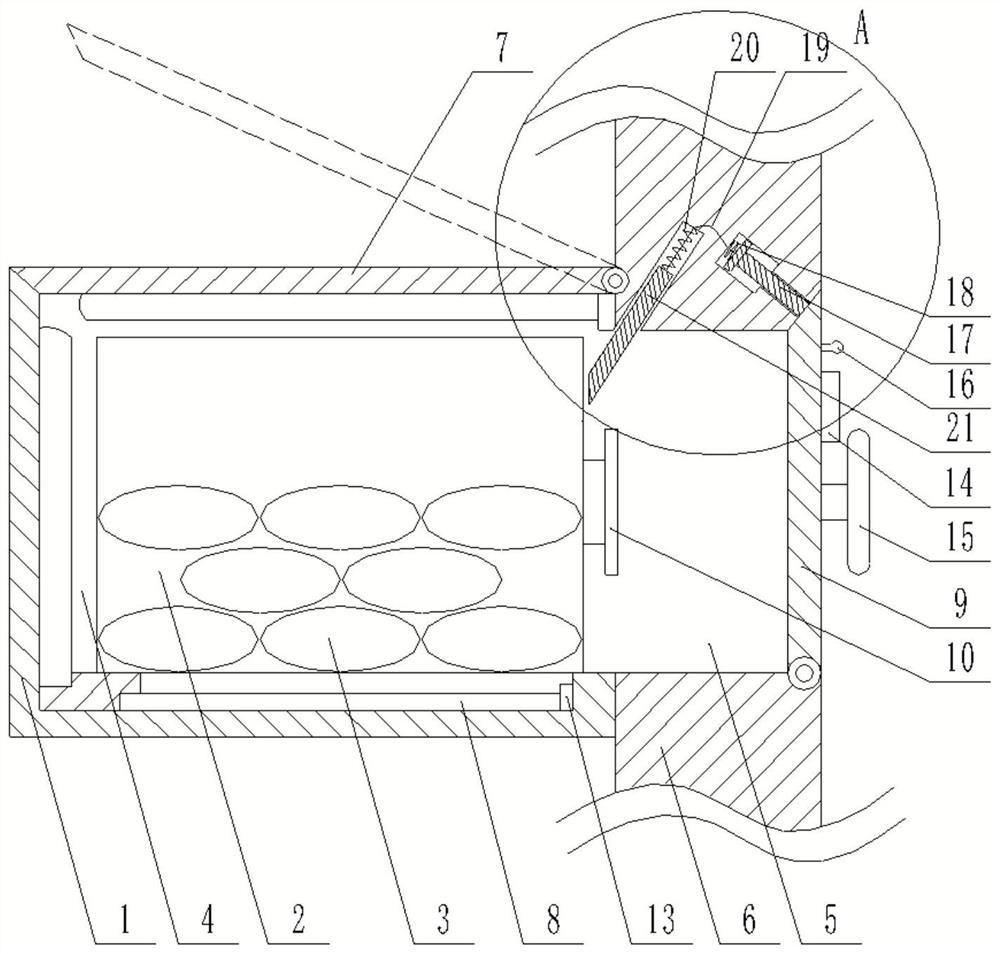

[0044] refer to Figure 3-4 , this embodiment provides a microwave disinfection transfer cabin for biological safety. The difference between this embodiment and Embodiment 1 is that the bottom end of the airtight hatch door 9 is hinged to the wall 6, and the wall at the top of the sliding chamber 5 6 is provided with a first chute and a second chute, a limit rod 21 is slidingly arranged in the first chute, one end of the limit rod 21 is in contact with the storage basket 2, and the other end of the limit rod 21 is in contact with the groove of the first chute. The first spring 20 is fixedly connected between the bottoms, the second chute is T-shaped, and a T-shaped block 17 is slidably arranged in the second chute, and one end of the T-shaped block 17 abuts against the airtight hatch 9, and the other end of the T-shaped block 17 A second spring 18 is fixedly connected between one end and the bottom of the second chute, the elasticity of the second spring 18 is greater than tha...

Embodiment 3

[0046] refer to Figure 5-8 , the present embodiment provides a microwave disinfection delivery cabin for biological safety. The difference between this embodiment and Embodiment 1 is that several handles 10 are provided on the basket 2, and the height of the basket 2 is smaller than that of the sliding chamber 5. Height, the bottom of the storage basket 2 is provided with a rotating disk 22, the side wall of the rotating disk 22 is slidingly connected with the wall 6 and the side wall of the main body of the transmission cabin 1, and two trapezoidal chutes 23 are provided in parallel on the rotating disk 22, and the bottom of the storage basket 2 is fixed A trapezoidal projection 24 matching the trapezoidal chute 23 is connected, the trapezoidal projection 24 is slidably connected with the trapezoidal chute 23, the bottom of the rotating disc 22 is fixedly connected with the output shaft of the drive motor 25, and the drive motor 25 is detachably provided with The sealing cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com