Breakage-proof logistics box for medical instrument logistics

A technology of medical equipment and logistics boxes, applied in the field of logistics boxes, can solve the problems of corrugated box tearing damage, affecting the compression resistance of the carton, bending deformation, etc., to ensure the compression and load-bearing capacity, improve the normal use performance, and reduce the large area Spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

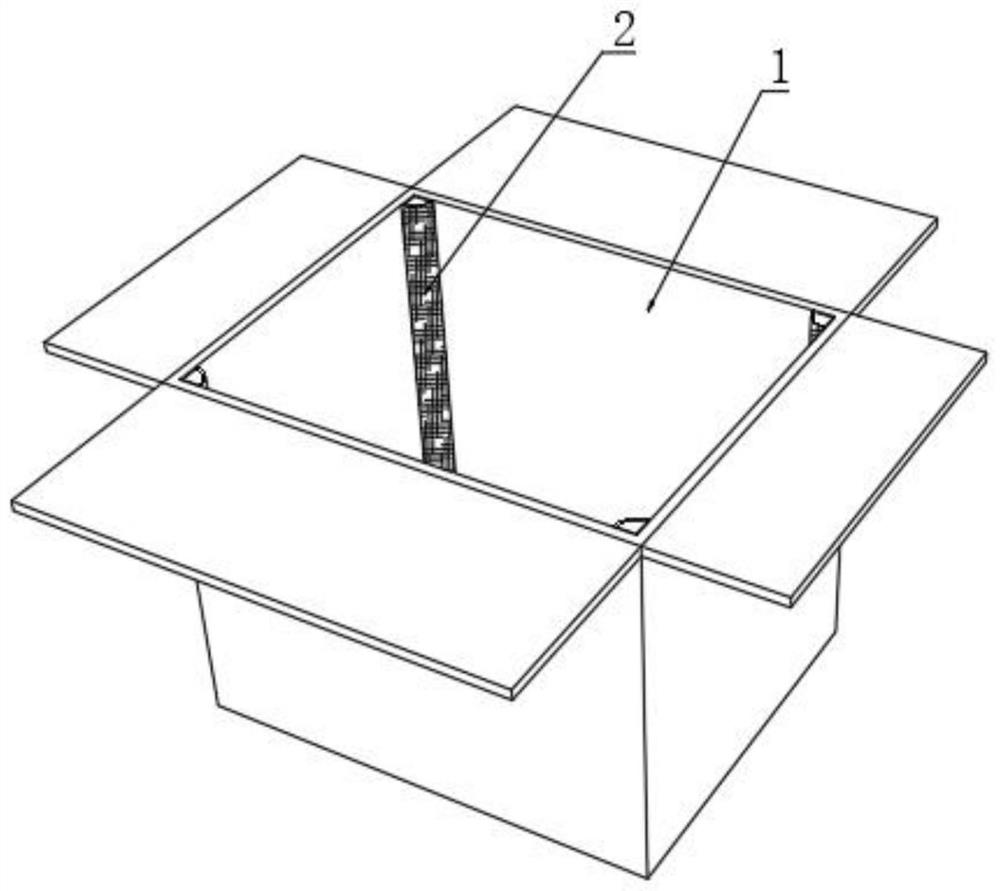

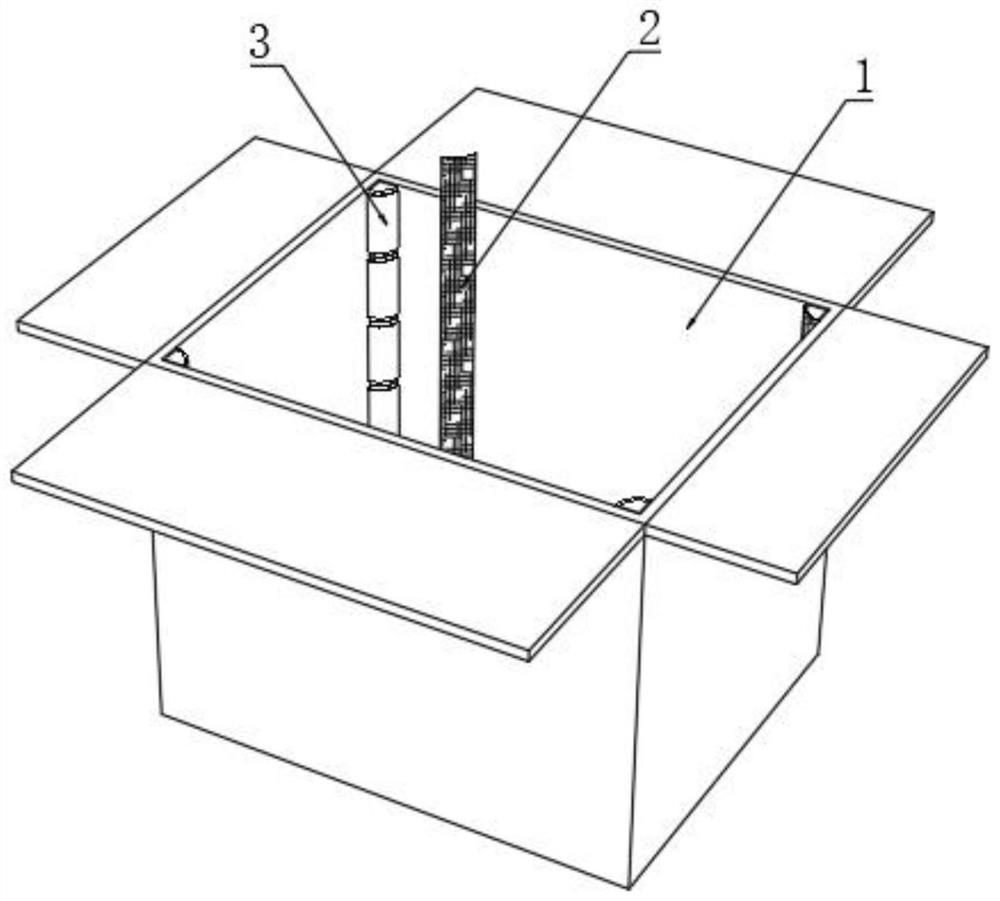

[0040] see figure 1 and figure 2 , an anti-damage logistics box for medical device logistics, comprising a corrugated box 1, a plurality of pressing cloths 2 are arranged inside the corrugated box 1, and the plurality of pressing cloths 2 are respectively located at multiple side corners of the corrugated box 1, and A pair of side ends of the press cloth 2 are respectively fixedly connected with a pair of inner walls of the corrugated box 1, and a plurality of dehumidification and pressure-resisting columns stacked up and down are arranged between the edges and corners of the press cloth 2 and the corrugated box 1 .

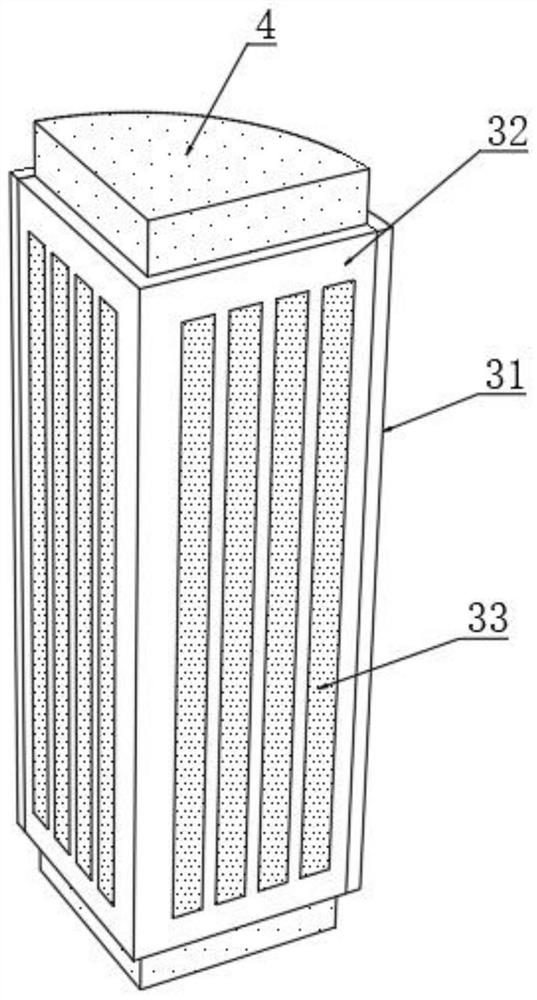

[0041] see image 3 and Figure 4, the dehumidification and anti-pressure column includes a hollow hard cover 3, the interior of the hollow hard cover 3 is fixedly connected with water storage cotton 4, the hollow hard cover 3 includes an arc-shaped sheet 31 and a right-angle plate 32, and the arc-shaped sheet 31 and the right-angle plate 32 form a quarter On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com