Fabricated external wall insulation board and installation method thereof

An external wall insulation board and assembly technology, which is applied in the direction of insulation, walls, building components, etc., can solve the problems of the outer surface of the insulation board, such as wear, uneven distribution of adhesives, and affect the appearance, so as to achieve convenient and accurate docking and follow-up Adjust, reduce the contact area, avoid the effect of friction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

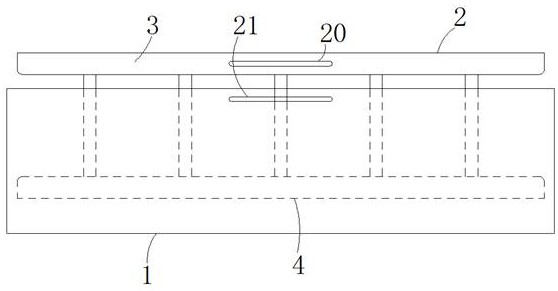

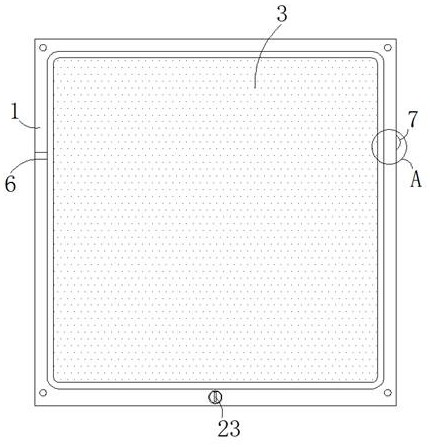

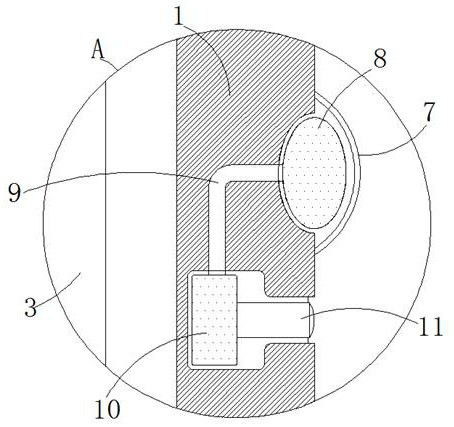

[0036] The assembled external wall insulation board includes an outer frame 1 and an insulation part 2, and the insulation part 2 includes an outer panel 3 and an inner panel 4, and also includes a connecting piece, which is used to connect the inner surfaces of the outer panel 3 and the inner panel 4, The outer frame 1 is fixed with partitions 5 distributed horizontally, the outer panel 3 and the inner panel 4 are respectively located on the upper and lower sides of the partition 5, and the connecting piece vertically runs through the partition 5, and the partition 5 and the connecting piece are in a sliding connection structure , the initial position of the outer plate 3 is located above the top of the outer frame 1, the initial position of the inner plate 4 is located inside the outer frame 1, and the inner part of the outer frame 1 is provided with grooves matching the outer plate 3 and the inner plate 4 respectively , and the outer surface of the inner plate 4 is a rubber ...

no. 2 example

[0041] In this embodiment, different from Embodiment 1, the connecting piece is a sliding rod 14, which is fixed at the center of the outer plate 3 and the inner plate 4, and the outer side of the sliding rod 14 is surrounded by a third air bag 15, The top of the third airbag 15 is fixed on the bottom of the dividing plate 5, and the bottom of the third airbag 15 is fixedly connected with the inner surface of the inner plate 4, and the outer plate 3 is pushed to drive the inner plate 4 to move downward through the slide bar 14. The three airbags 15 expand under tension to achieve heat preservation effect, and the inside of the third airbag 15 is also provided with a connecting rope 16, the two ends of the connecting rope 16 are all fixed in the inner wall of the third airbag 15, and the inside of the third airbag 15 is filled with down Part 17, the third airbag 15 is stretched and expanded so that the down piece 17 fills the inside of the third airbag 15, so that the third airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com