Calibration device for underground bit pressure and torque measurement short section

The technology of torque measurement and calibration device is applied in the direction of measurement, automatic control system of drilling, earthwork drilling, etc. It can solve the problems of inconvenient handling of heavy weights, easy deformation of lever arm, and easy error of calibration device, etc. Achieve the effect of improving calibration accuracy and calibration efficiency, improving control precision and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

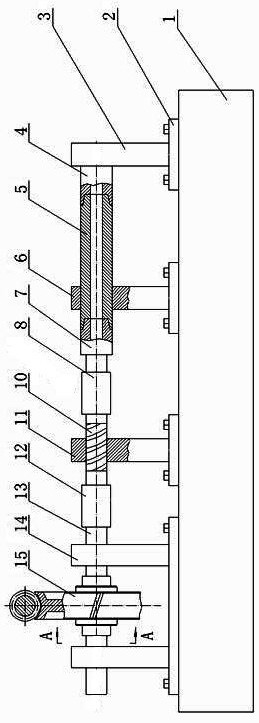

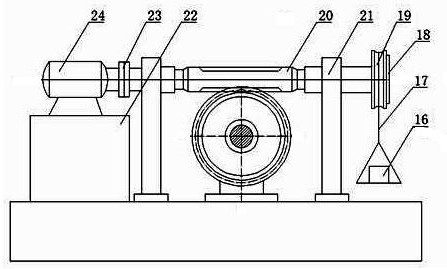

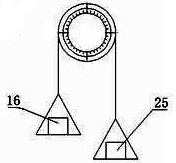

[0040] see Figure 1-Figure 3 , a calibration device for downhole drilling pressure torque measurement pup, including a base 1, the base 1 is fixedly connected with a pup fixed support 3, a pup righting support 6, a screw support 11, and a worm gear support 14 , worm support 21 and motor support 22, the short joint fixed support 3 is connected with a short joint fixed head 4, and a measuring pup joint 5 is arranged between the short joint fixed support 3 and the short joint righting support 6, A short joint conversion head 7 is connected to the measuring pup joint 5, and a lead screw 10 is arranged between the screw support 11 and the pup joint righting support 6, and the lead screw 10 is connected to the lead screw support 11 by threads. One end of the bar 10 is connected with a variable connection sleeve 8, the nipple conversion head 7 is connected with the variable connection sleeve 8, a worm gear shaft 13 is arranged between the worm gear support 14 and the lead screw supp...

Embodiment 2

[0043] see Figure 1-Figure 3 , a calibration device for downhole drilling pressure torque measurement pup, including a base 1, the base 1 is fixedly connected with a pup fixed support 3, a pup righting support 6, a screw support 11, and a worm gear support 14 , worm support 21 and motor support 22, the short joint fixed support 3 is connected with a short joint fixed head 4, and a measuring pup joint 5 is arranged between the short joint fixed support 3 and the short joint righting support 6, A short joint conversion head 7 is connected to the measuring pup joint 5, and a lead screw 10 is arranged between the screw support 11 and the pup joint righting support 6, and the lead screw 10 is connected to the lead screw support 11 by threads. One end of the bar 10 is connected with a variable connection sleeve 8, the nipple conversion head 7 is connected with the variable connection sleeve 8, a worm gear shaft 13 is arranged between the worm gear support 14 and the lead screw supp...

Embodiment 3

[0047] see Figure 1-Figure 3 , a calibration device for downhole drilling pressure torque measurement pup, including a base 1, the base 1 is fixedly connected with a pup fixed support 3, a pup righting support 6, a screw support 11, and a worm gear support 14 , worm support 21 and motor support 22, the short joint fixed support 3 is connected with a short joint fixed head 4, and a measuring pup joint 5 is arranged between the short joint fixed support 3 and the short joint righting support 6, A short joint conversion head 7 is connected to the measuring pup joint 5, and a lead screw 10 is arranged between the screw support 11 and the pup joint righting support 6, and the lead screw 10 is connected to the lead screw support 11 by threads. One end of the bar 10 is connected with a variable connection sleeve 8, the nipple conversion head 7 is connected with the variable connection sleeve 8, a worm gear shaft 13 is arranged between the worm gear support 14 and the lead screw supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com