Aviation single crystal blade non-metal contact unshelling tool

A single crystal blade, non-metallic technology, applied in the field of non-metallic contact shelling tooling for aviation single crystal blades, can solve problems such as disorderly placement of single crystal blades, recrystallization, bumps, and scratches of single crystal blades, and achieve shortening Hulling time, improved shelling efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

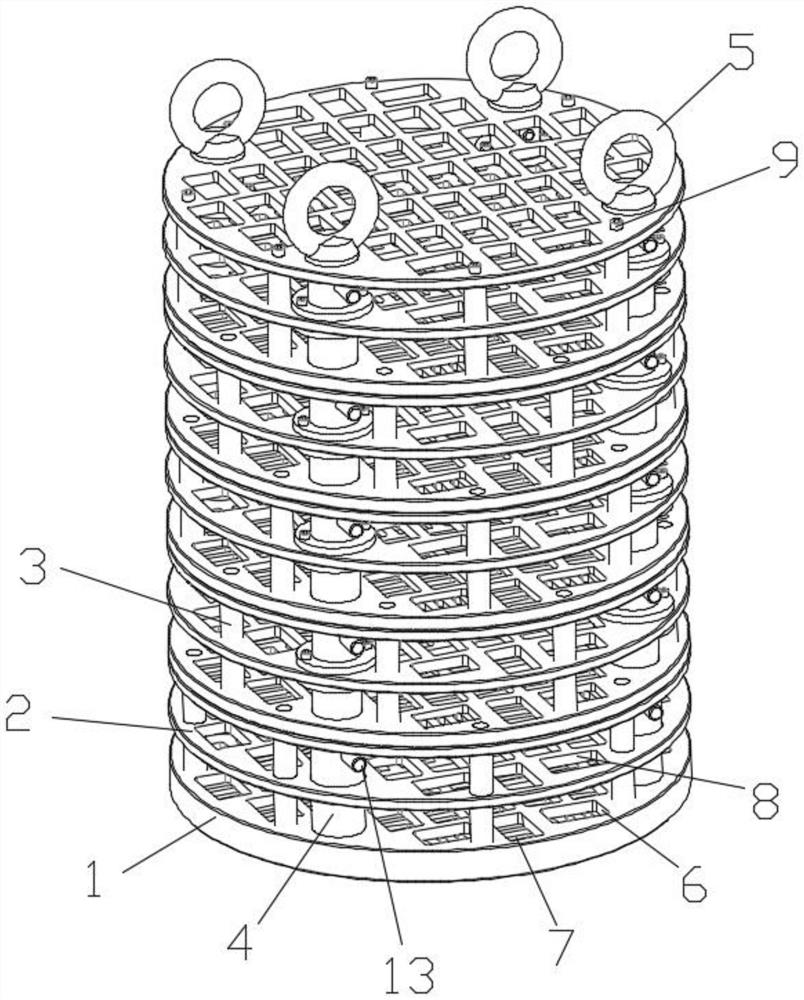

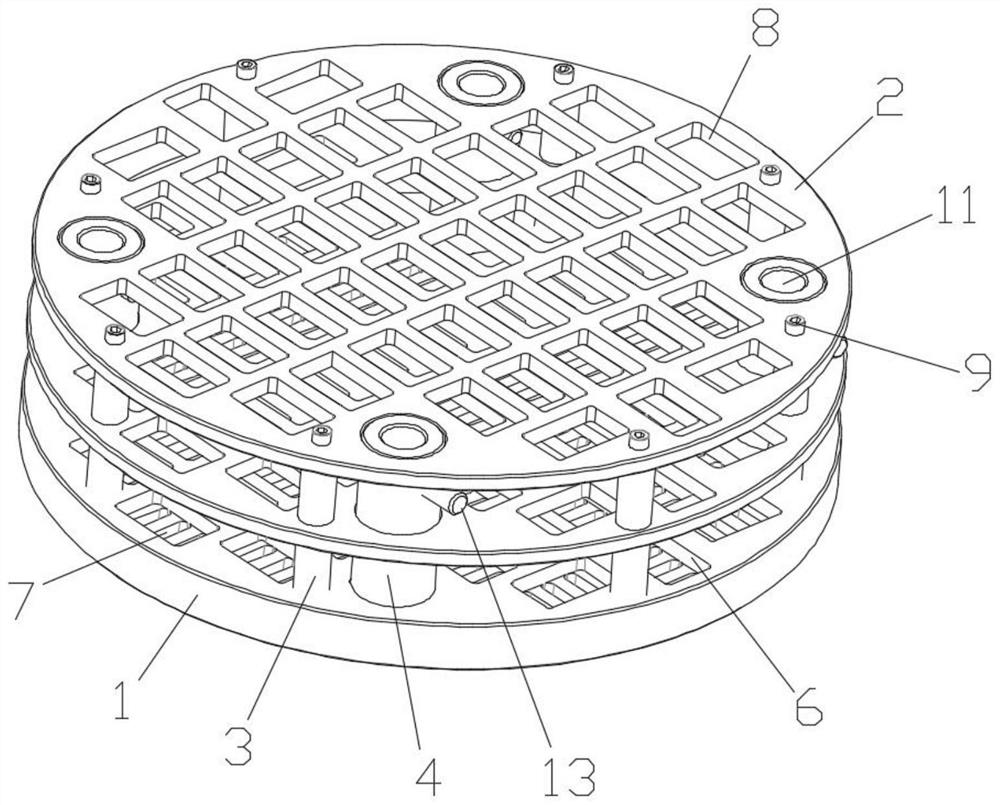

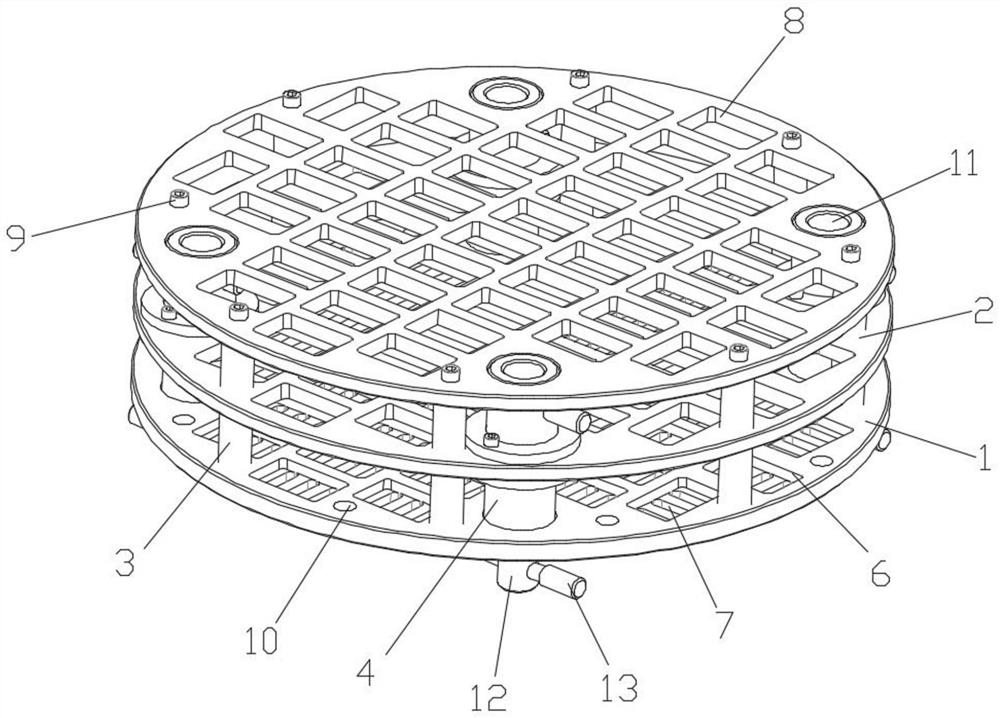

[0019] Such as Figure 1-3 As shown, a non-metallic contact shelling tool for aviation single crystal blades includes several stacked unit placement racks, and the unit placement racks include a base 1, at least one positioning plate 2, connecting rods 3 and lifting columns 4. The base 1 and the positioning plate 2 are fixedly connected by connecting rods 3, the adjacent unit placement frames are connected by lifting columns 4, the ends of the uppermost lifting columns 4 are fixedly connected to the lifting ring 5, and the base 1 and the positioning plate 2 are made of non-metallic materials.

[0020] In this embodiment, the upper end surface of the base 1 is provided with a plurality of placement grooves 6, the bottom of the placement groove 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com