Multifunctional pressure plate assembly for cutting machine

A cutting machine, multi-functional technology, applied in the cutting of textile materials, textile and papermaking, metal processing and other directions, can solve the problem that the single platen assembly cannot be accurately set, affecting the cutting efficiency and the quality of the cutting piece, the platen and the cutter head. Easy to fall off and other problems, to achieve the effect of improving cutting effect, preventing falling off and offset, and simplifying and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

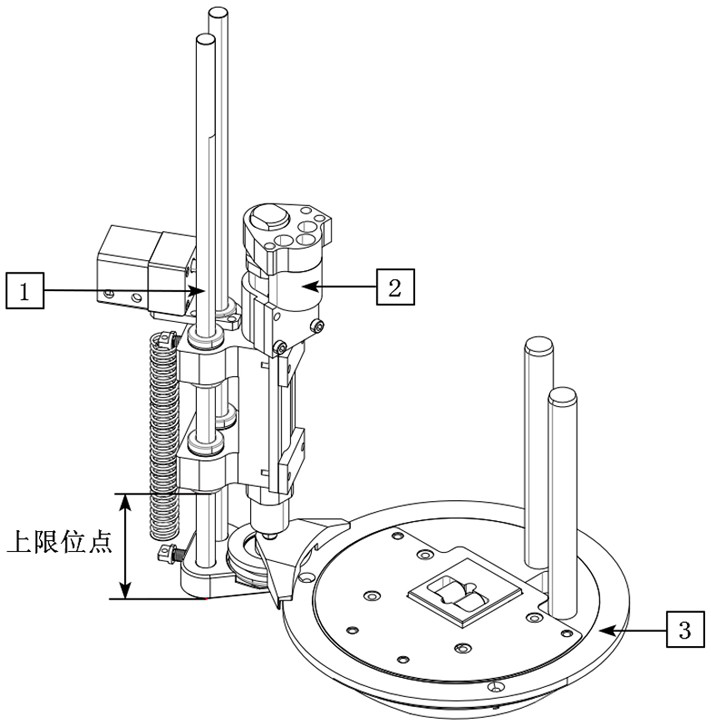

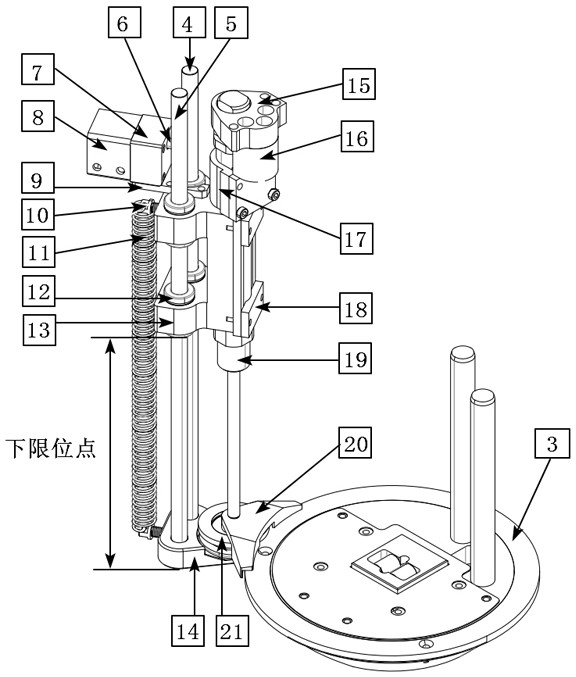

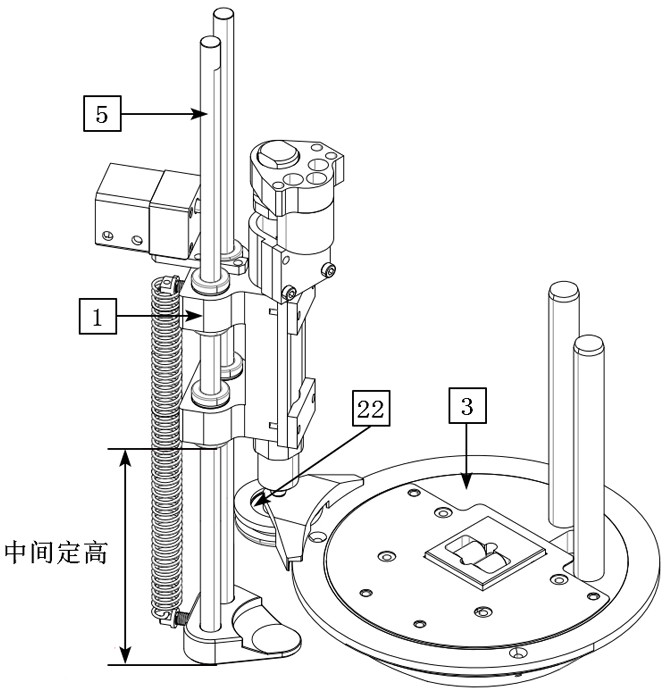

[0024] combined with Figures 1 to 4 , a multi-functional platen assembly for a cutting machine, which includes a height-fixing assembly 1 and a main platen assembly 2, the lower part of the main platen assembly 2 is provided to ensure that the cutter head assembly 3 of the cutting machine can rotate and cut smoothly The position-limiting mechanism; the height-fixing component 1 and the pressure plate main component 2 are installed side by side, the height-fixing component 1 is equipped with a supporting plate for supporting the position-limiting mechanism, and the supporting plate is connected on the supporting plate. A height-fixed telescopic device; after the height setting of the supporting plate, the working height of the limit mechanism and the cutter head assembly 3 is synchronized by supporting the limit mechanism.

[0025] As a preference, said plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com