Precision machining process for hole system of main motor supporting plate of numerical control mine rope sawing machine

A technology of precision machining and main motor, applied in the direction of metal processing equipment, manufacturing tools, accessories of toolholders, etc., to achieve high precision, improve dimensional accuracy, and ensure high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

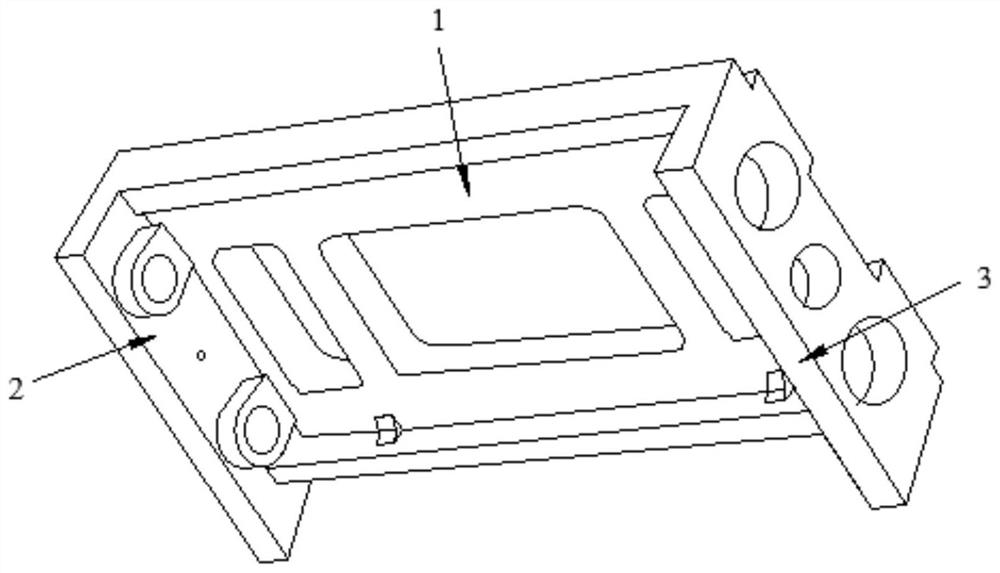

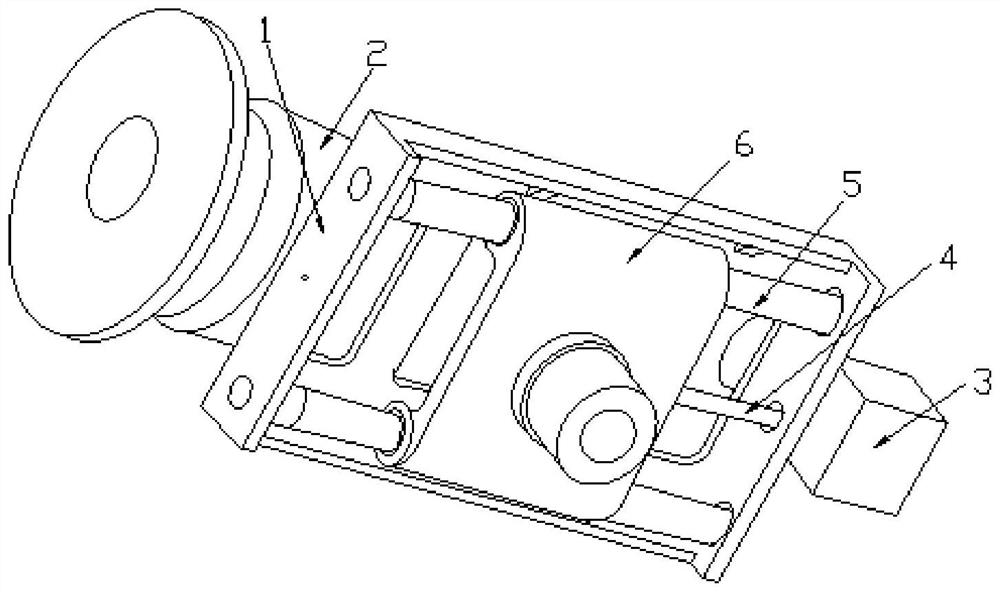

[0027] as attached figure 1 to attach image 3 Shown:

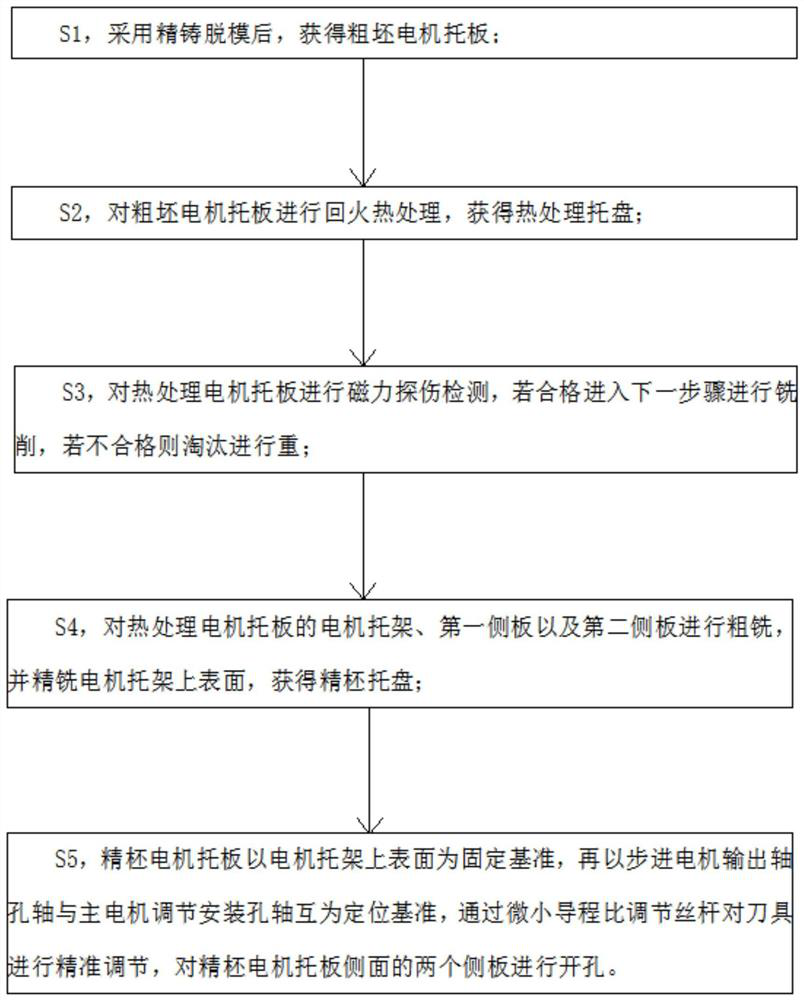

[0028] The present invention provides a precision machining process for the 1-hole system of the main motor support plate of a numerically controlled mine wire saw machine, which includes the following steps:

[0029] S1, after precision casting is used for demoulding, a rough motor pallet 1 is obtained;

[0030] S2, performing tempering heat treatment on the rough motor pallet 1 to obtain a heat treatment tray;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com