Offshore wind turbine floating transportation and installation system

An offshore wind turbine and installation system technology, which is applied in the direction of wind turbine transportation, transportation and packaging, and installation/support configuration of wind turbines, can solve the problems of difficulty in the installation process, high transportation and installation costs, and reduce transportation and installation costs. The effect of improving installation efficiency and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

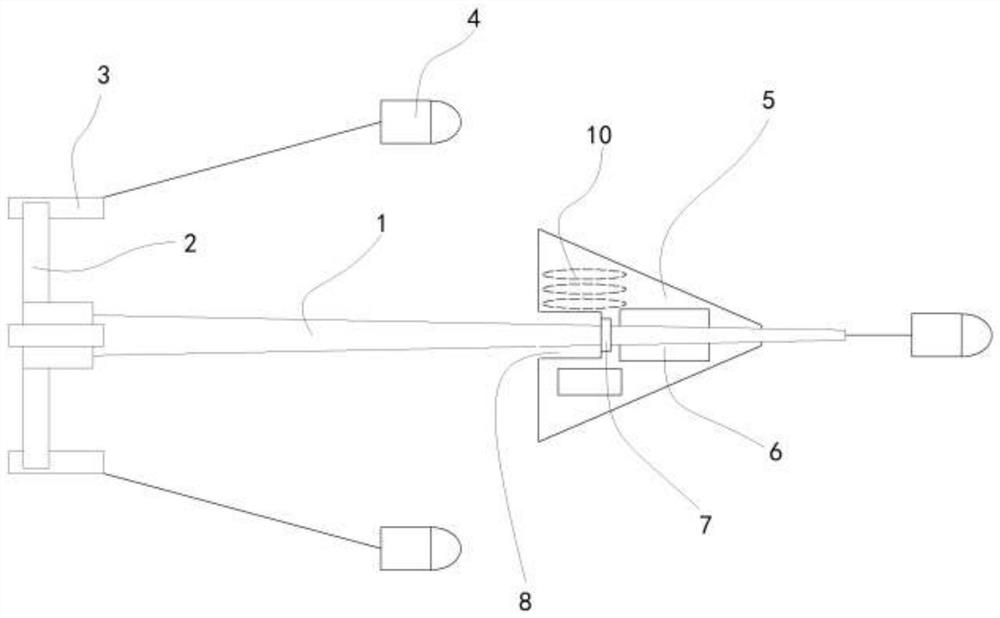

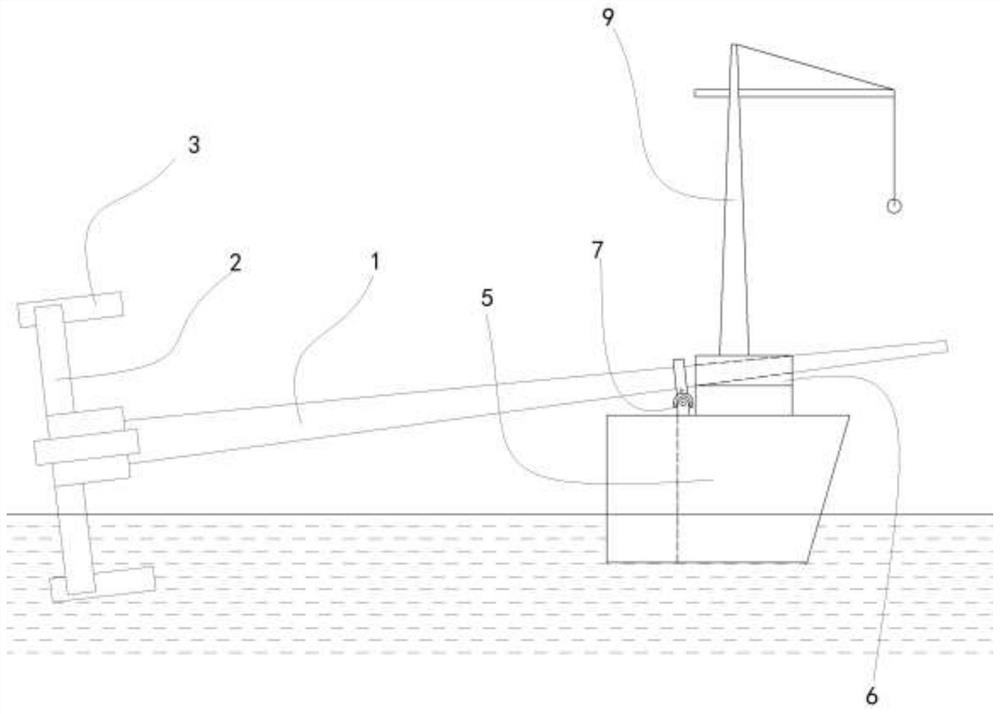

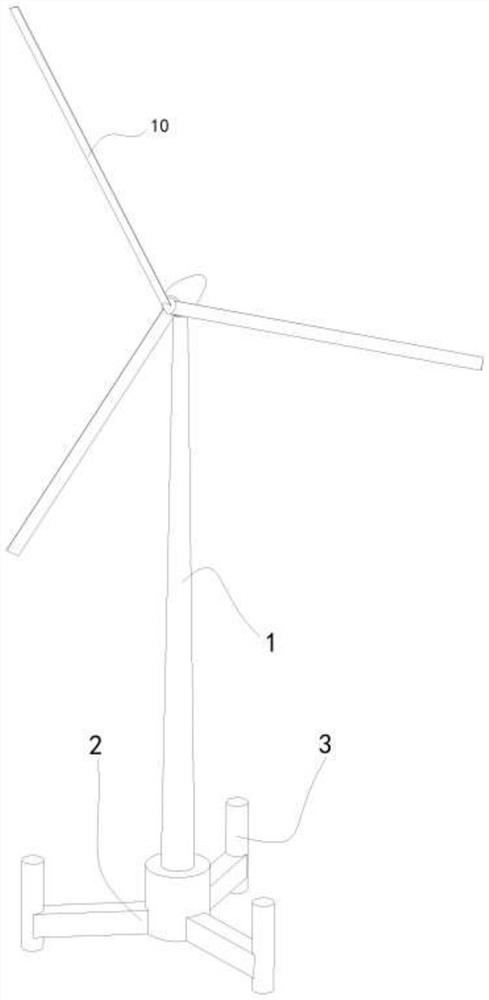

[0027] Such as figure 1 As shown, the offshore wind turbine floating transportation installation system includes a buoyancy base 2 , an operation and maintenance platform and a tugboat 4 .

[0028] The buoyancy base 2 is arranged at the bottom of the wind turbine tower 1, a ballast water tank is arranged inside the buoyancy base 2, the submersible pump and the water level sensor are arranged inside the ballast water tank, and the submersible pump It communicates with the water inlet and outlet of the ballast water tank.

[0029] The middle of the superstructure of the operation and maintenance platform 5 is provided with a tower groove 6 adapted to the side wall of the fan tower 1, the rear end of the tower groove 6 is fixed to one end of the universal joint 7, and the universal joint 7 The other end of the section 7 is provided with a hoop collar sheathed on the fan tower 1 .

[0030] The three tugboats 4 are respectively connected to both sides of the buoyancy base 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com