Microwave ferrite material for third-order intermodulation circulator and preparation method thereof

A ferrite material, third-order intermodulation technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, inorganic materials, etc. It can solve the problems of deterioration of communication system performance, affecting network coverage and capacity, and reducing Loss of the device, optimized sintering process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] This embodiment provides a microwave ferrite material for a third-order intermodulation circulator and a preparation method thereof, and the preparation method includes the following steps:

[0086] (1) Weighing: According to the composition chemical formula of microwave ferrite material is Y 3-a Ca a sn a In b mn c Fe 5-a-b-c o 12 (a=0.27, b=0.01, c=0.05) Weigh the corresponding raw materials, where Y 2 o 3 The purity is 99.95%, CaCO 3 The purity is 99.5%, SnO 2 The purity is 99.5%, In 2 o 3 The purity is 99.99%, MnCO 3 The purity is 99%, Fe 2 o 3 The purity is 99.5%;

[0087] (2) One-time ball milling: Pour the raw materials weighed in step (1) into a ball mill tank and mix them with a ball mill. According to the mass ratio, raw materials: deionized water: zirconia balls = 1:1:6, and add acetone as a dispersion dispersant, the rotating speed of ball milling is 60rpm, the time is 35h, and the first slurry is obtained after ball milling; the mass proporti...

Embodiment 2

[0094] This embodiment provides a microwave ferrite material for a third-order intermodulation circulator and a preparation method thereof, except that the composition chemical formula of the microwave ferrite material is Y 3-a Ca a sn a In b mn c Fe 5-a-b-c o 12 (a=0.26, b=0.01, c=0.02), and change the concentration of co-solvent in step (4) in the second slurry to 100ppm in the preparation method, and the rest of the conditions are the same as in Example 1, so in I won't go into details here.

Embodiment 3

[0096]This embodiment provides a microwave ferrite material for a third-order intermodulation circulator and its preparation method, except that the temperature of the third sintering in step (6) in the preparation method is changed to 1510°C, and the other conditions are the same as those in Embodiment 1. are the same, so I won’t repeat them here.

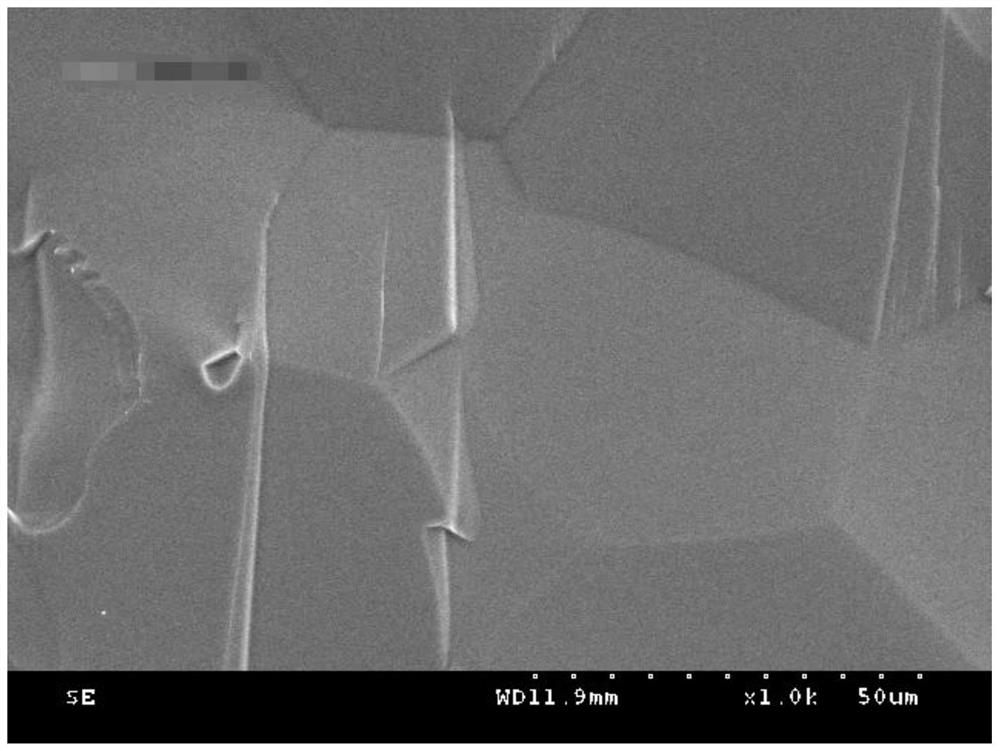

[0097] The sintered crystal image of the microwave ferrite material obtained in this embodiment is shown in figure 2 .

[0098] Depend on figure 2 It can be seen that compared with Example 1, the third sintering temperature of this example is too high, resulting in more defects on the crystal surface of the obtained microwave ferrite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com