Magnetic suspension bearing-based thrust vectoring nozzle for rocket projectile

A magnetic levitation bearing and thrust vectoring technology, which is applied in the field of vector nozzles, can solve the problems such as the difficulty of designing the control actuation system to be light, the cost and the weight of the aircraft, and achieve high utilization of axial space, high critical rotor speed, and improved performance. The effect of changing direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described with reference to the accompanying drawings.

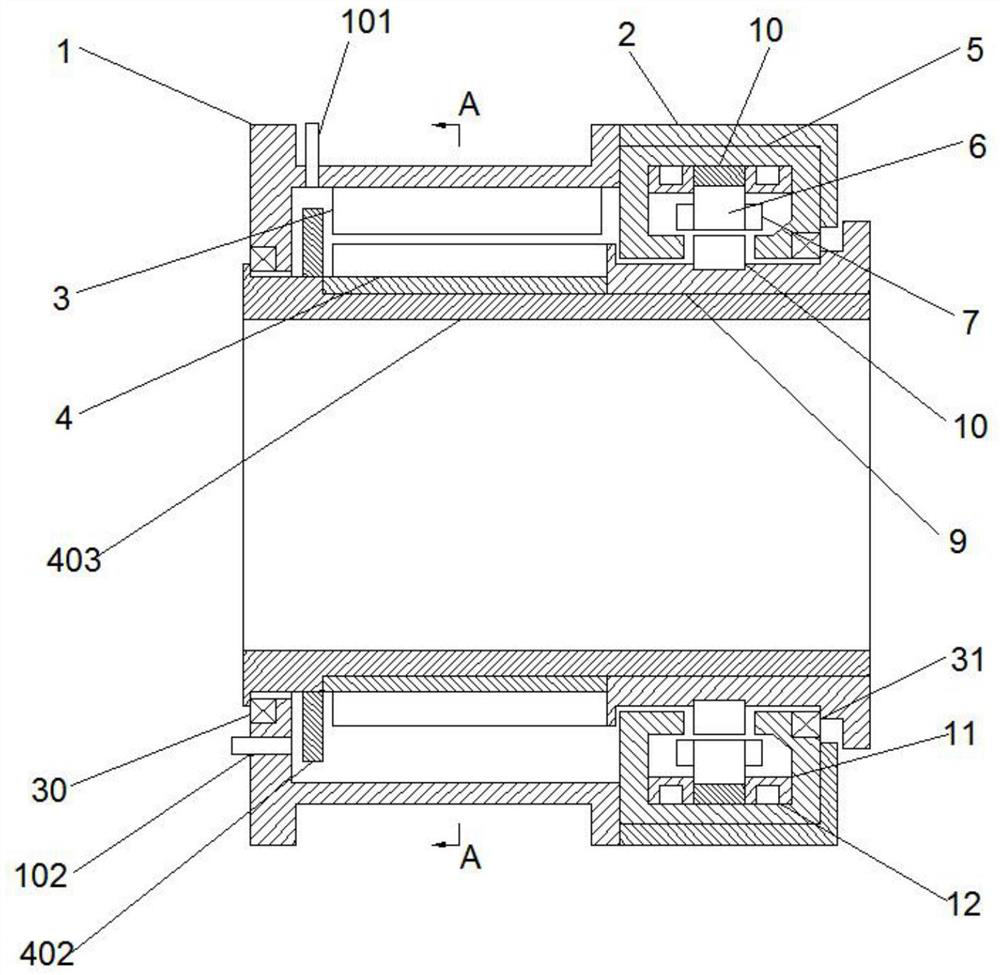

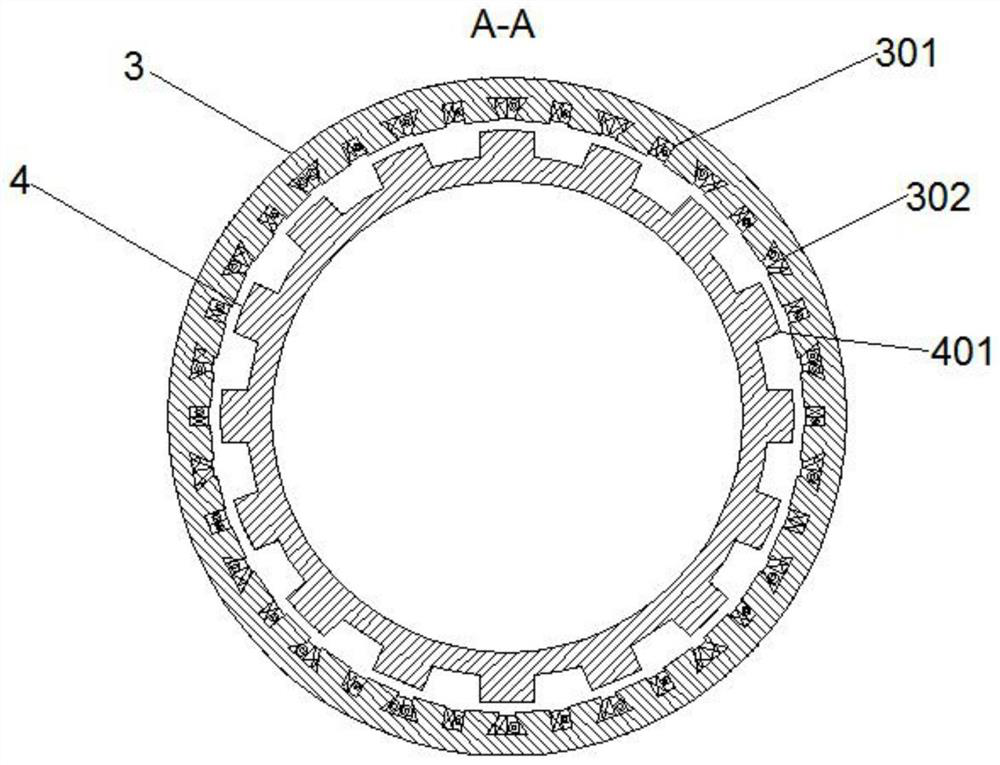

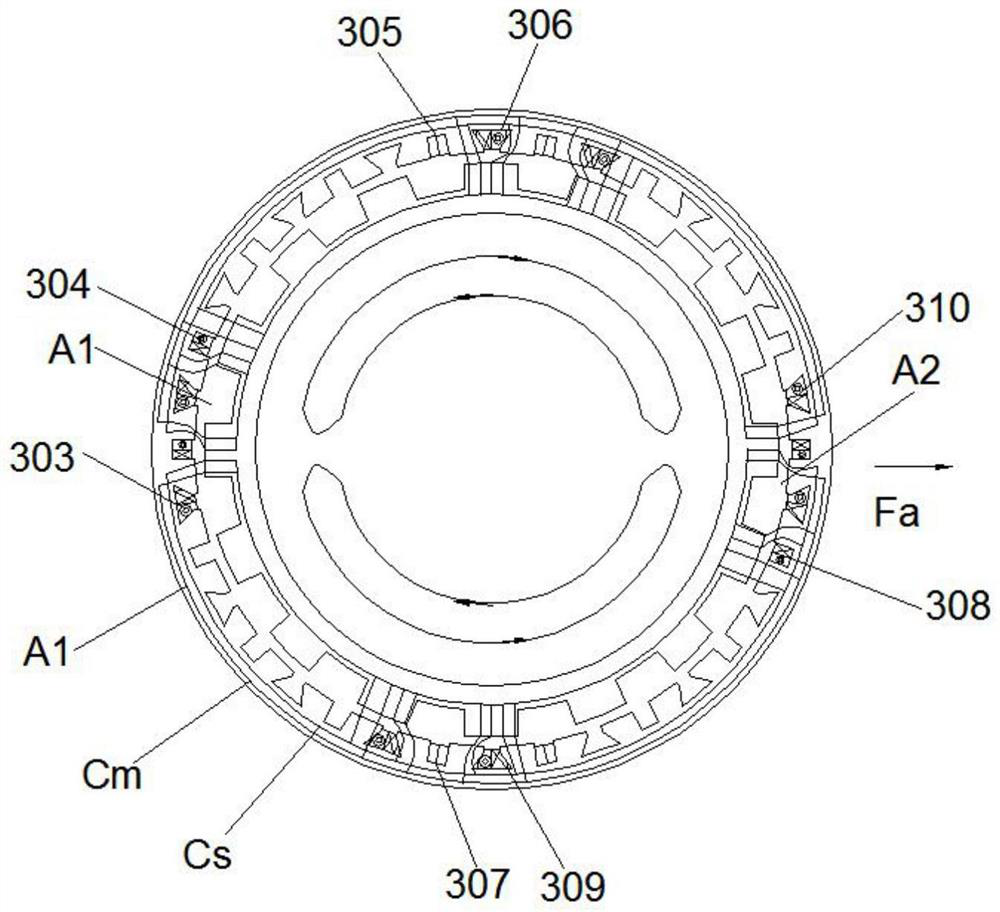

[0029] A thrust vectoring nozzle for rockets based on magnetic suspension bearings, including a secondary motor 1, the secondary motor 1 includes two parts: a motor body and a magnetic suspension bearing, the motor body includes two parts: a motor stator 3 and a motor rotor 4, and the motor stator is divided into three parts It consists of two parts, the suspension tank 301 and the rotation tank 302. The suspension coils represented by the first suspension wire package 304, the second suspension wire package 305, the third suspension wire package 307 and the fourth suspension wire package 308 are installed in the suspension tank 301. The suspension wire package is composed of two rectangular coils in series, and the two adjacent suspension wire packages are connected by the connection method of "head joint, tail to tail". The first rotating wire package 303 and the second ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com