Heat dissipation shell, processing method thereof and conduction heat dissipation module

A technology of a heat dissipation shell and a processing method, which is applied in the direction of modification, cooling/ventilation/heating transformation, and support structure installation through conduction and heat transfer. High efficiency, low cost, and the effect of improving contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

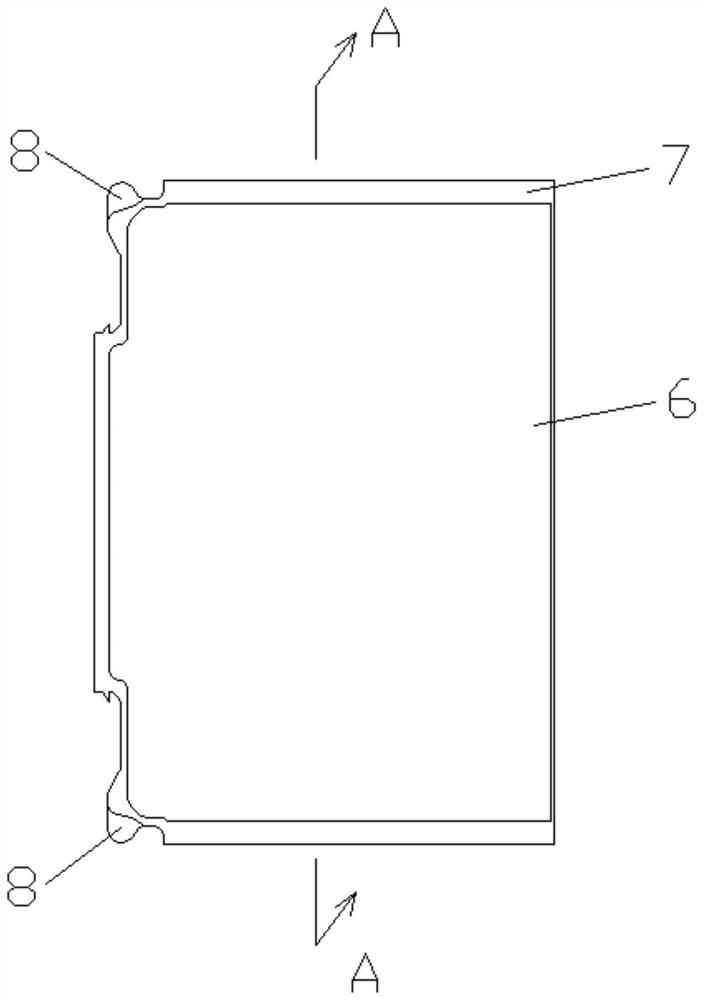

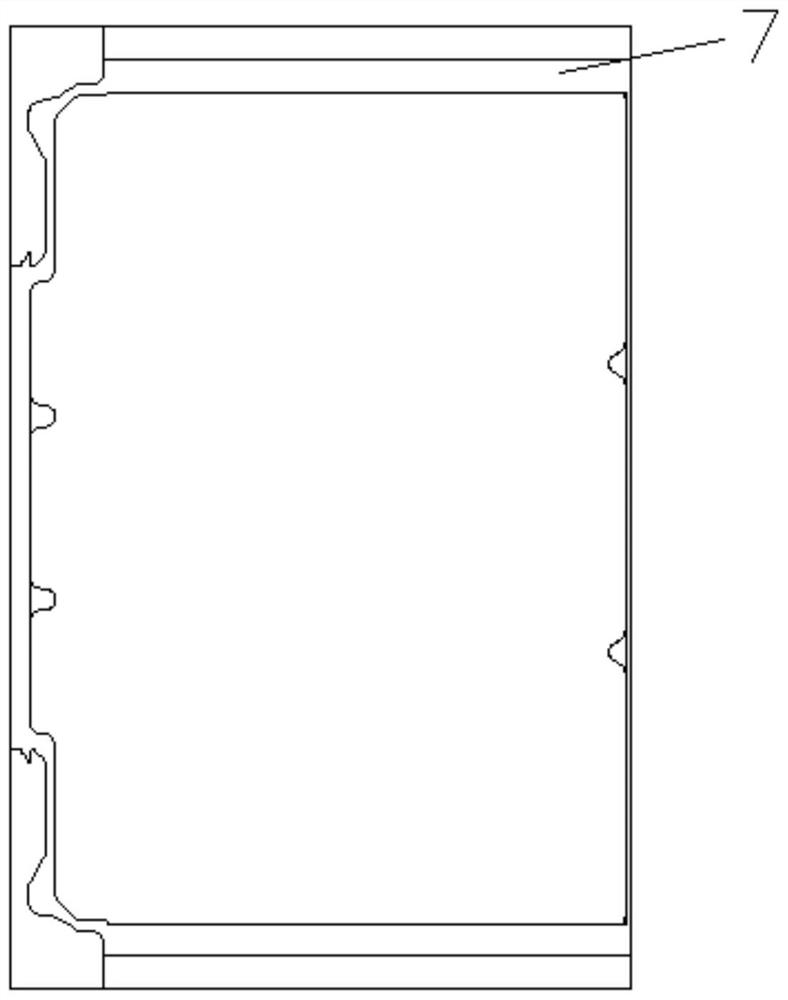

[0046] On the basis of the above structure, in this embodiment, the other side of the frame 7 is fixedly connected with an extension part, and the extension part is used for fixing the PCB board 3 . The solution is simple in structure and reasonable in design, and the extension part is integrally formed with the frame 7 to increase the internal space of the frame 7 and facilitate the installation of the PCB board 3 .

Embodiment 2

[0048] On the basis of Embodiment 1, in this embodiment, the extension part is preferably a frame-shaped structure that matches the shape of the frame 7 , which facilitates the fixed installation of the PCB 3 during installation and ensures the stability of the installation of the PCB 3 .

[0049] Based on the above solution, the thickness of the extension part can be equal to the thickness of the frame 7 or smaller than the thickness of the frame 7, preferably the latter, which is convenient for installing the PCB board 3 and saves space.

Embodiment 3

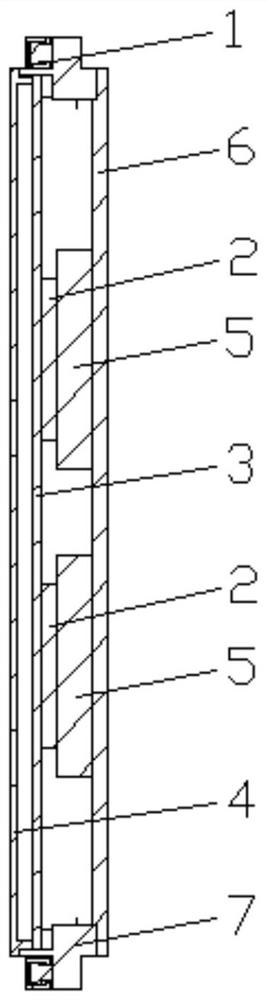

[0051] On the basis of any one of Embodiment 1 to Embodiment 2, in this embodiment, the extension part is covered with a cover plate 4 . The cover plate 4 forms a closed shell with the frame 7 and the heat transfer bottom plate 6, which facilitates the subsequent installation of the PCB board 3 and the chip 2 and forms a suitable working environment.

[0052] Based on the solution of Embodiment 1, the cover plate 4 is directly fixed on the other side of the frame 7 at this time.

[0053] Based on the solution of Embodiment 2, the cover plate 4 is fixedly installed on the extension of the frame 7 at this time, so that the space enclosed between the cover plate 4, the heat transfer bottom plate 6 and the frame 7 is larger, and it is convenient to install the PCB board 3 and chip 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com