5G antenna shell integrated punching device

A technology for antenna shells and stamping equipment, which is applied in the field of presses, can solve the problems of waste of machining precision shell materials, troublesome steps, large errors, etc., and achieve the effects of saving manual zeroing time, improving efficiency, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

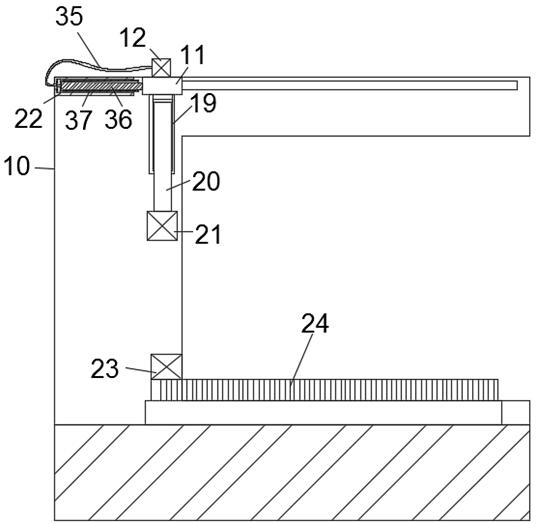

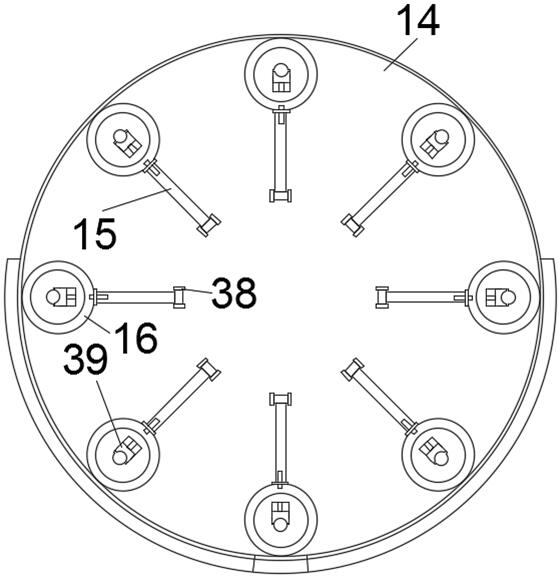

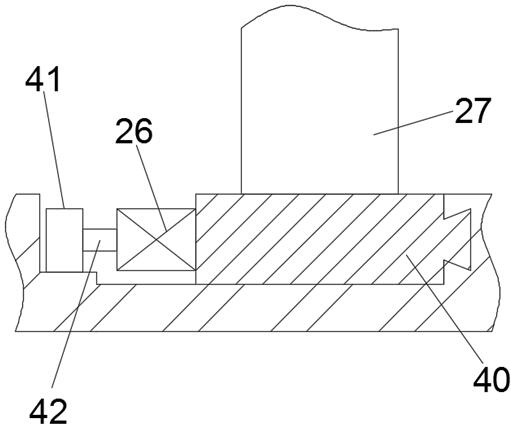

[0024] refer to Figure 1-6 , according to an embodiment of the present invention, a 5G antenna casing integrated stamping equipment includes a casing 10, a moving cavity 65 communicating with the outside is provided in the casing 10, and a sliding connection is slidably connected to the right end surface of the casing 10. block 11, the lower end surface of the sliding block 11 is fixedly connected with a sleeve 19, and the sleeve 19 is slidably connected with a sealing rod 20, and the sealing rod 20 is fixedly connected with a conversion motor 21, and the conversion motor 21 is power connected with a conversion shaft 18, the conversion shaft 18 is fixedly connected with a tool conversion frame 14, and the tool conversion frame 14 is fixedly connected with eight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com