Machine tool for machining turbine blades

A technology of blades and turbines, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of the final workpiece processing accuracy, inconvenient operation, etc., and achieve the effect of reducing space interference and iron filings splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

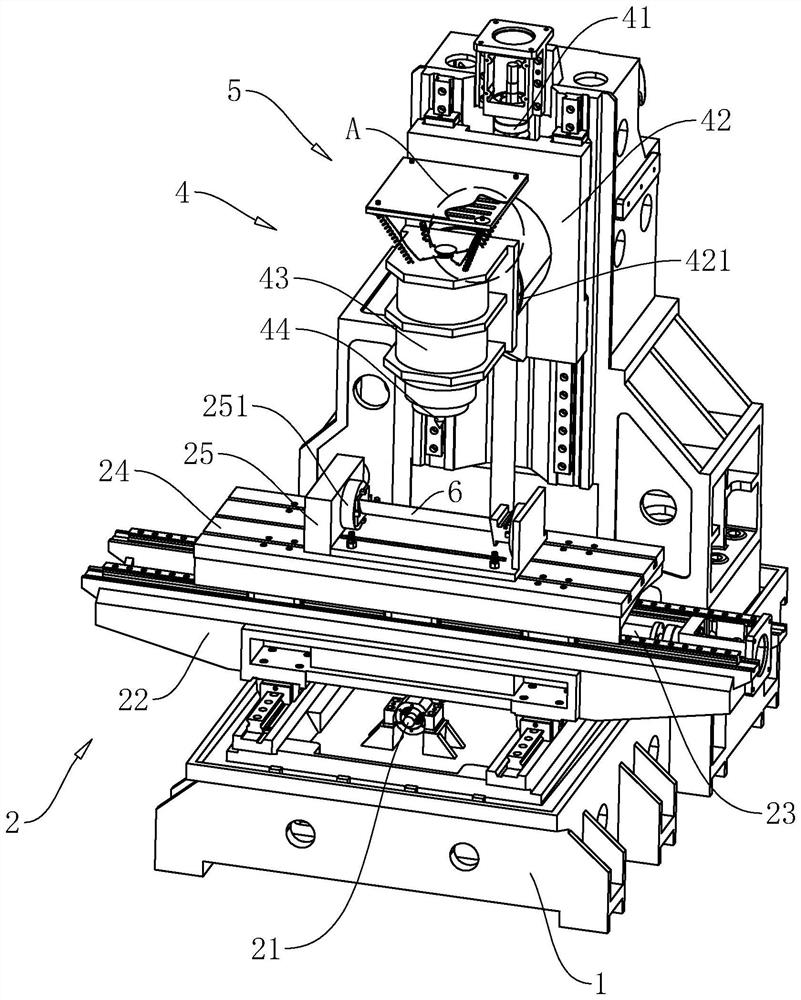

[0033] The following is attached Figure 1-5 The application is described in further detail.

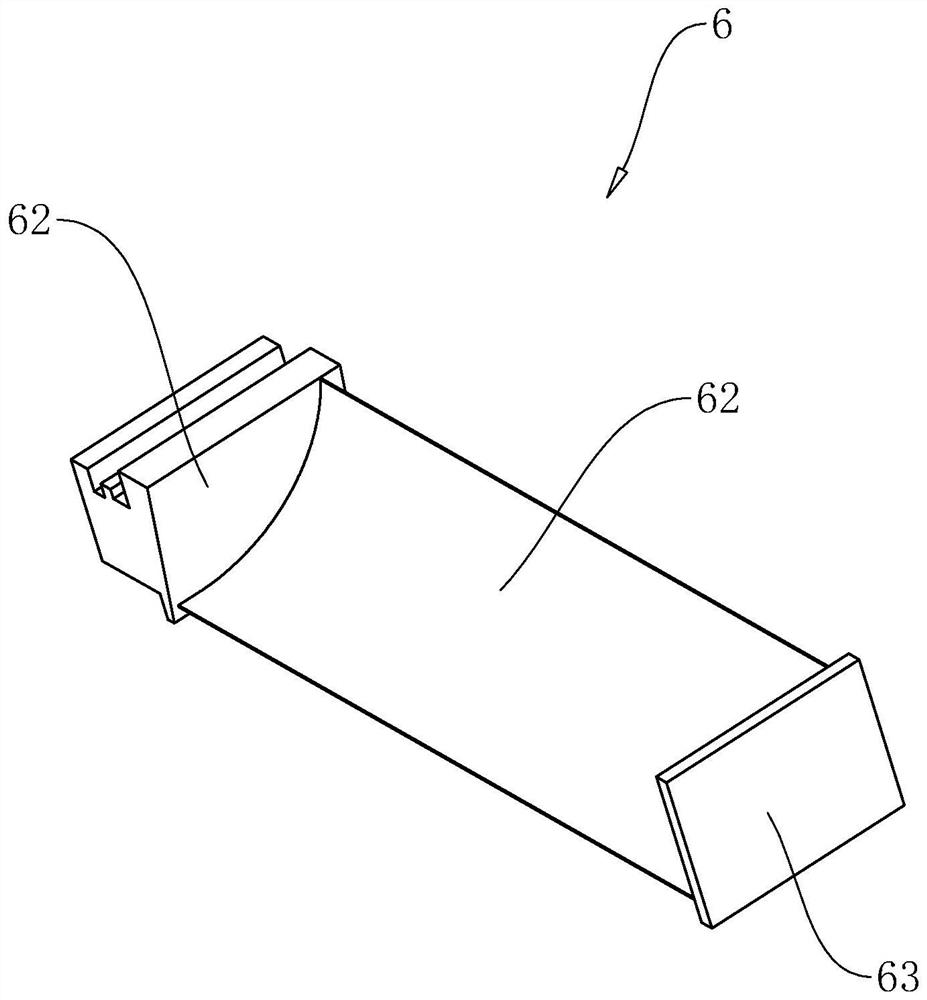

[0034] The embodiment of the present application discloses a machine tool for turbine blade processing, such as figure 2 As shown, it includes a frame 1, and the frame 1 is provided with a placement mechanism 2, a cutting mechanism 4 and a chip removal mechanism 5; the placement mechanism 2 is used to fix and adjust the attitude of the blade workpiece 6, and the cutting mechanism 4 includes a processing tool 44, It is used for milling the blade workpiece 6 , the machining tool 44 is a milling cutter, and the chip removal mechanism 5 is used for cleaning the iron filings generated during processing.

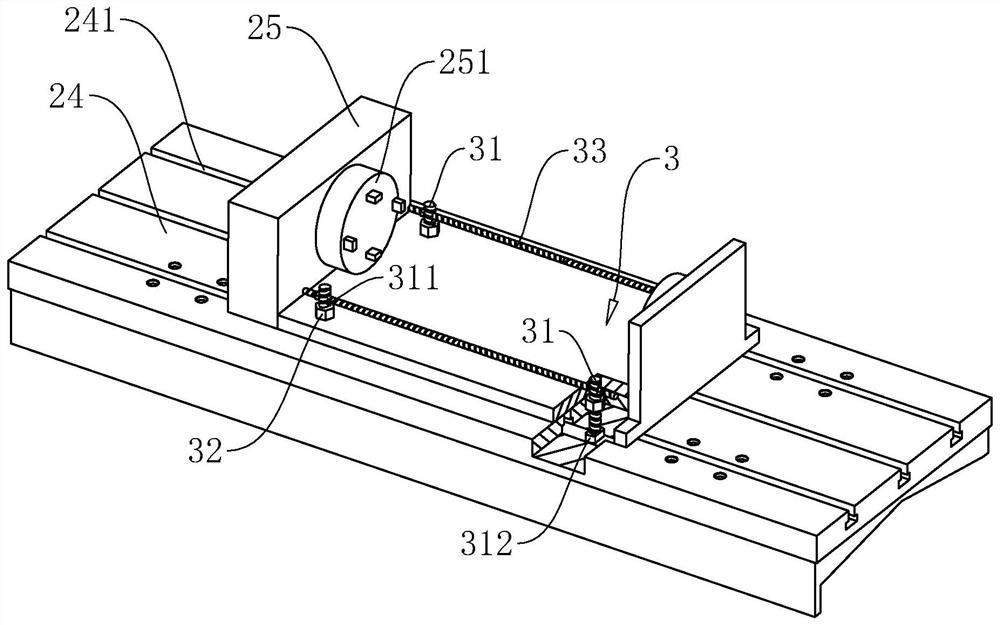

[0035] like figure 2 As shown, the placement mechanism 2 includes a first screw mandrel 21, a mounting base 22, a second screw mandrel 23 and a placement table 24, the mounting base 22 is slidably connected to the frame 1, and the first screw mandrel 21 is rotationally connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com