Auxiliary device for maintenance of luffing mechanism and gantry crane

A technology of luffing mechanism and auxiliary device, which is applied in the direction of crane, load block, transportation and packaging, etc., and can solve the problems of dispatching external equipment and arranging auxiliary structures, a large number of tooling and welding work, more labor and maintenance time, etc. Achieve the effects of reducing space interference, improving efficiency, and saving cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

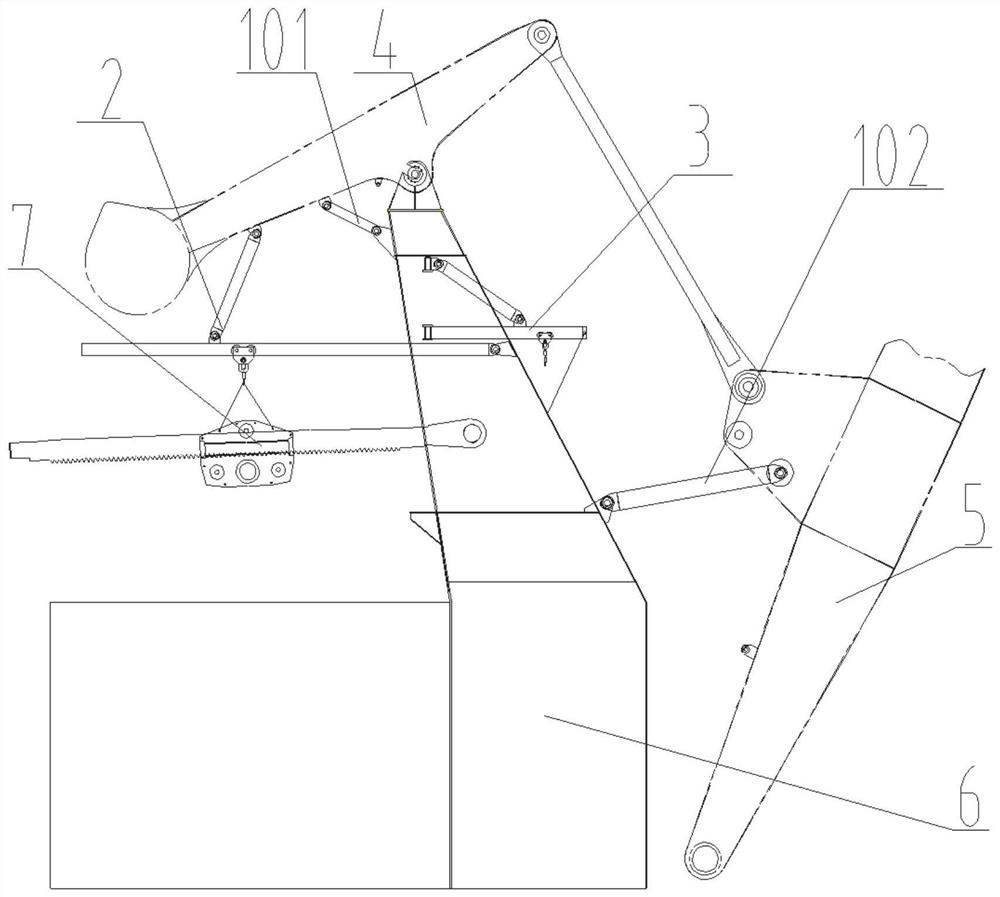

[0035] In a typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown, an auxiliary device for the maintenance of the luffing mechanism is proposed.

[0036] The auxiliary device mainly includes a binding assembly, a first assembly and a second assembly. The binding assembly is used to constrain the movement of the four-link balance structure of the crane so that the four-link balance structure of the crane is in a fixed state. Through the first assembly and the second assembly Suspension maintenance hoist, wire rope, sling and other lifting maintenance tools, maintenance and transfer of parts of the dismantled luffing mechanism;

[0037] The first component is a rotating maintenance crane component, which is used for maintenance, short-distance transfer and movement of various parts of the luffing mechanism; the second component is a four-link maintenance crane component, which is used for maintenance and transfer of various parts of the luffing me...

Embodiment 2

[0082] In another typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown, a working method using the auxiliary device in embodiment 1 is proposed.

[0083] Include the following steps:

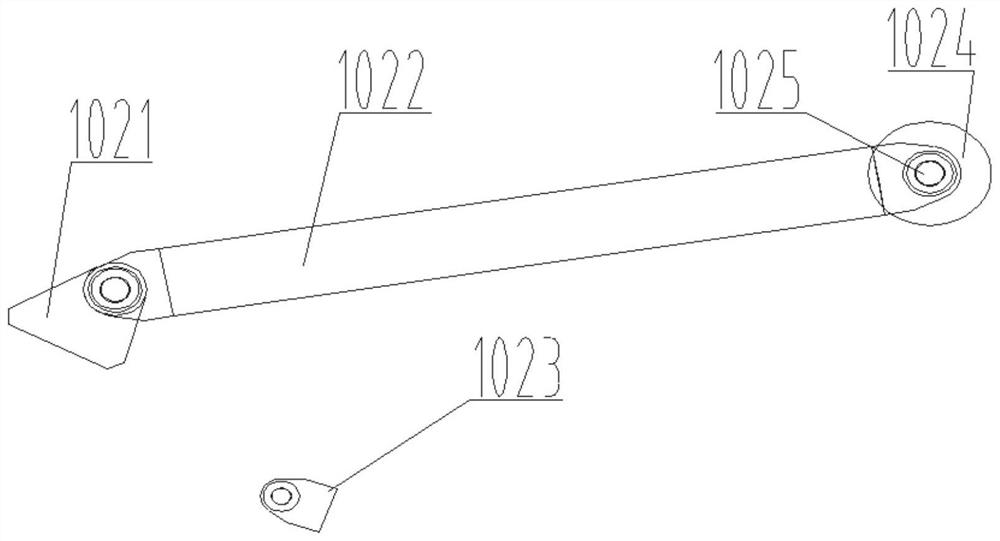

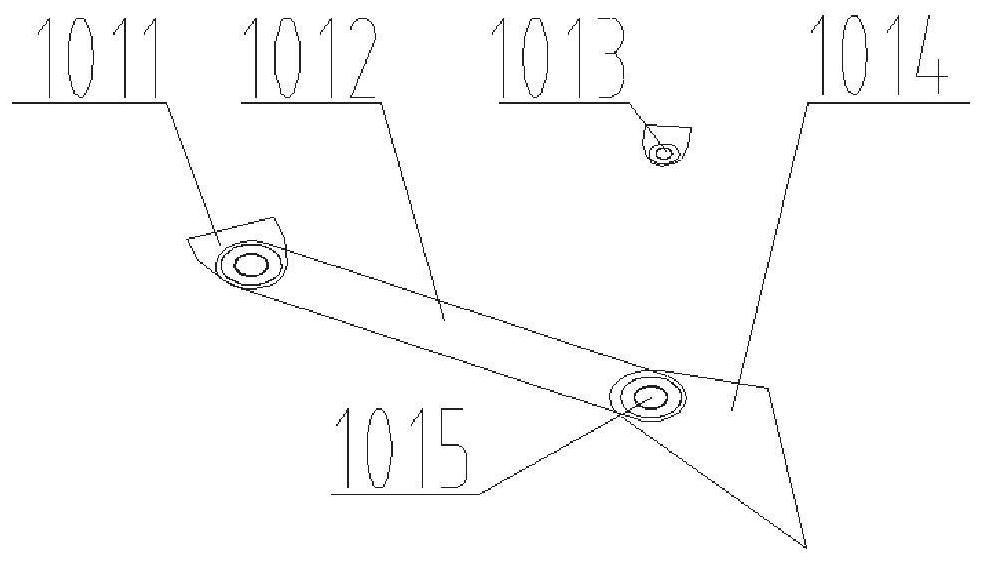

[0084]When the door machine is working normally, the front pull rod 1022 in the binding assembly 1 is fixed on the second fixing seat 1023, and swings with the arm frame 5, and the rear strut 1012 in the binding assembly 1 is fixed on the first fixing seat 1013, and moves with the balance Beam 4 swings;

[0085] The four-link maintenance crane assembly 2 forms a four-bar linkage mechanism with the balance beam 4 and the column 6, and the movable link 202 and the second slide bar 203 move with the flapping of the balance beam 4; the rotating maintenance crane assembly 3 passes through the traction chain 304 Be fixed on one side wall of column 6.

[0086] During the maintenance of the luffing mechanism, the rear strut 1012 in the strapping assembly 1 is fixed on...

Embodiment 3

[0092] In yet another typical implementation of the present disclosure, such as Figure 1-Figure 6 As shown, a portal crane is proposed, utilizing an auxiliary device for luffing mechanism maintenance as described in Example 1.

[0093] It includes the frame, the four-link balance structure of the crane and the auxiliary device for the maintenance of the luffing mechanism as described in Embodiment 1; the four-link balance structure of the crane is installed on the frame, and the auxiliary device is correspondingly installed on the four-link crane In terms of balance structure, the luffing mechanism is maintained;

[0094] The specific cooperation relationship between the crane's four-bar linkage balance structure and the auxiliary mechanism is as described in Embodiment 1, and the arrangement is made with reference to the description in Embodiment 1, and will not be repeated here.

[0095] By arranging the auxiliary device directly on the four-link balance structure of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com